When it comes to drilling, the efficiency and durability of your equipment can make all the difference. DTH (Down-The-Hole) hammers are essential tools in mining, construction, and quarrying, designed to deliver powerful impact energy directly to the drill bit. Choosing the right hammer design can significantly affect drilling speed, energy consumption, and overall operational costs.

DTH hammers come in various designs, each tailored for specific drilling needs and ground conditions. Understanding the key differences between these designs helps operators select the most suitable hammer for their project, ensuring optimal performance, longer equipment life, and improved drilling precision.

What are DTH Hammers?

Recommended DTH Hammers

DTH (Down-The-Hole) hammers are specialized drilling tools used in mining, construction, and quarrying to efficiently break through hard rock and soil. Unlike conventional drilling methods, a DTH hammer delivers percussive energy directly to the drill bit at the bottom of the hole, minimizing energy loss and maximizing drilling speed. This makes them ideal for deep drilling projects where precision and efficiency are critical.

A DTH hammer consists of a piston, hammer body, and drill bit, powered by compressed air. The piston strikes the drill bit repeatedly, while the surrounding air helps remove cuttings from the hole. This design allows for faster penetration, reduced wear on the drill string, and more consistent hole quality, making DTH hammers a preferred choice for both small- and large-scale drilling operations.

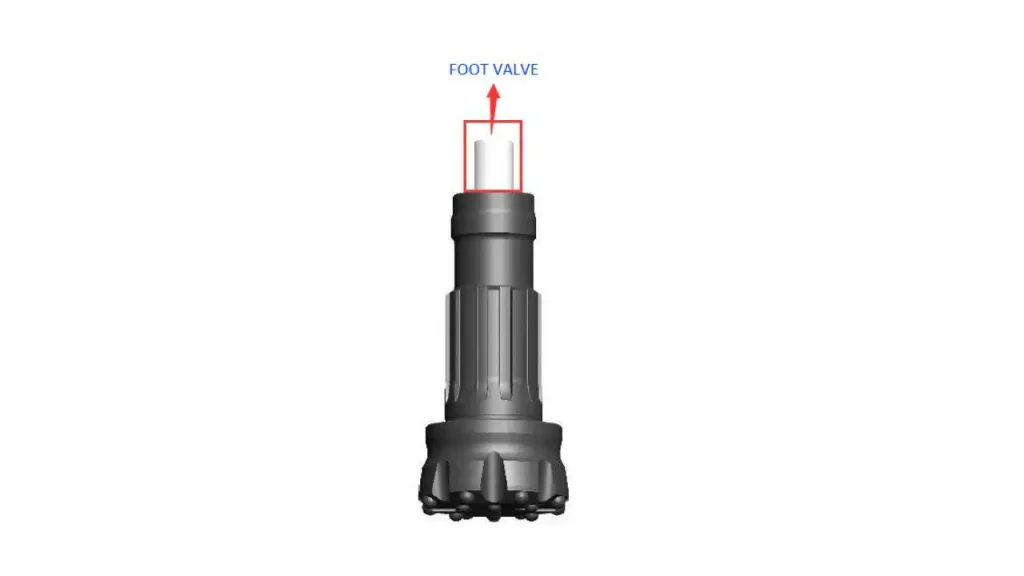

DTH hammers designed for DTH bits with foot vavle V.S DTH hammers designed for DTH bits without foot valve

DTH drill bits and hammers use compressed air to generate impact energy, driving the drill bit to perform drilling operations. The DTH hammer contains a precise air distribution system consisting of an air distributor , internal cylinder, piston, and piston case. Its working principle involves entering compressed air into the DTH hammer, causing the piston to reciprocate within this system, converting air energy into mechanical energy, and ultimately transmitting it to the drill bit to break the rock.

1. DTH Hammers for DTH Bits with Foot Valve:

Blow tube, plastic tube, tube, foot valve, all refer to the same item.

Regular DTH product series with foot valve include:

DHD series: DHD3.5, DHD340, DHD350, DHD360, DHD380

QL series: QL40, QL50, QL60, QL80

SD series: SD4, SD5, SD6, SD8

COP series: COP34, COP44, COP54, COP64, COP84

In these DTH hammers, the foot valve works in conjunction with the piston based on a sealing principle, acting as a valve within the hammer to control air distribution. Typically, these DTH hammers have a heavier and shorter piston with more space in their air distribution system. This configuration allows for a lower impact frequency yet greater force per impact under the same air pressure, making them suitable for very hard rock formation.

Additional advantages of DTH hammers for DTH bits with foot valve include:

1. Airflow Control:

The foot valve adjusts the flow of compressed air entering the hammer. As the piston moves down, it allows air into the hammer, thus forming a high-pressure zone. This high-pressure air is then released through the drill bit, producing the necessary impact force to break rock.

2. Pressure Maintenance:

The foot valve helps maintain the necessary pressure inside the hammer. Proper pressure control ensures efficient operation of the hammer and provides the required impact energy to the drill bit. It also prevents pressure overloads, which can damage equipment or reduce drilling efficiency.

3. Directional Control:

In some DTH hammers, the foot valve also acts as a directional control. It directs airflow to different parts of the hammer, allowing the piston to move and ensuring the correct transference of impact energy to the drill bit.

2. DTH Hammers for DTH Bits without Foot Valve:

Regular DTH product series without foot valve include:

Mission series: Mission 30, Mission 40, Mission 50, Mission 60, Mission 80.

COP series: COP32, COP42, COP52, COP62.

BR series: BR2, BR3, BR4.

DHD-N series, improved series based on DHD : DHD2.5N, DHD3.5N, DHD340N, DHD350N, DHD360N, DHD380N.

QL-N series, improved series based on QL: QL50N, QL60N, QL80N.

In these hammers, the smaller lower end of the piston interacts with a guide sleeve, taking on the role of the foot valve. Unlike the DTH hammers with a foot valve, these have a longer piston and a more compact air distribution system, resulting in a shorter piston stroke, faster impact frequency, and less force per impact. Therefore, non-foot valve DTH hammers are more suited to soft or medium soft rock formation.

Additional advantages of DTH hammers for DTH bits without a foot valve include:

- High drilling speeds, the drilling speed is 15%-30% higher than that one with a foot valve.

- Out of issues due to foot valve breakage, damage, thermal expansion, and contraction.

- Lower air Consumption, reduced fuel consumption: over 10% savings compared to DTH hammers with foot valves.

- Simpler internal structure, lower overall failure rate, less frequent dismantling, and reduced downtime for clients.

Clients should choose the most suitable DTH product series based on the rock conditions they need to drill, and can also consult the Sinodrills sales team in advance.

We not only provide reliable products, but also offer professional guidance and suggestions!

Conclusion

Choosing the right DTH hammer design directly impacts drilling efficiency, equipment longevity, and overall project costs. Conventional hammers offer durability and reliability, while high-speed hammers excel in faster penetration and specialized applications. Understanding their differences ensures your operations run smoothly and effectively.

Proper selection and maintenance of DTH hammers can significantly improve drilling productivity. By matching hammer design to specific rock conditions, operators reduce energy waste, minimize bit wear, and achieve better hole quality. This knowledge empowers drilling teams to work smarter and more efficiently.

For businesses seeking quality equipment, Sinodrills offers a wide range of DTH hammers and drill bits at wholesale prices. Partnering with us ensures access to reliable, high-performance drilling tools that enhance your project outcomes and maximize operational value.