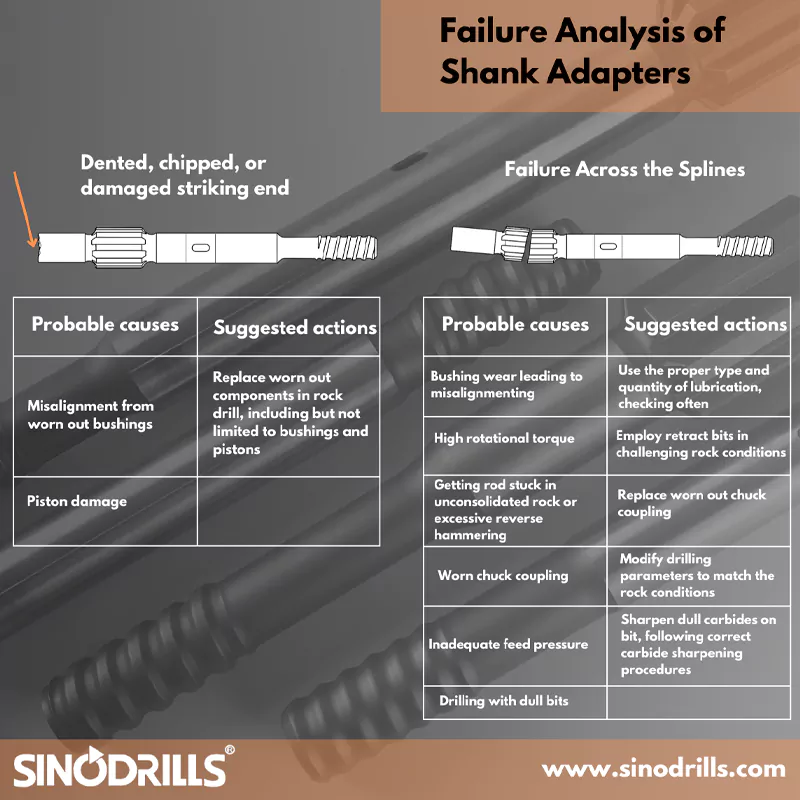

1. Dented, chipped, or damaged striking end

Probable causes:

– Misalignment from worn out bushings

– Piston damage

Suggested actions:

– Replace worn out components in rock drill, including but not limited to bushings and pistons

2. Failure Across the Splines

Probable causes:

– Bushing wear leading to misalignment

– High rotational torque

– Getting rod stuck in unconsolidated rock or excessive reverse hammering

– Worn chuck coupling

– Inadequate feed pressure

– Drilling with dull bits

Suggested actions:

– Use the proper type and quantity of lubrication, checking often

– Employ retract bits in challenging rock conditions

– Replace worn out chuck coupling

– Modify drilling parameters to match the rock conditions

– Sharpen dull carbides on bit, following correct carbide sharpening procedures

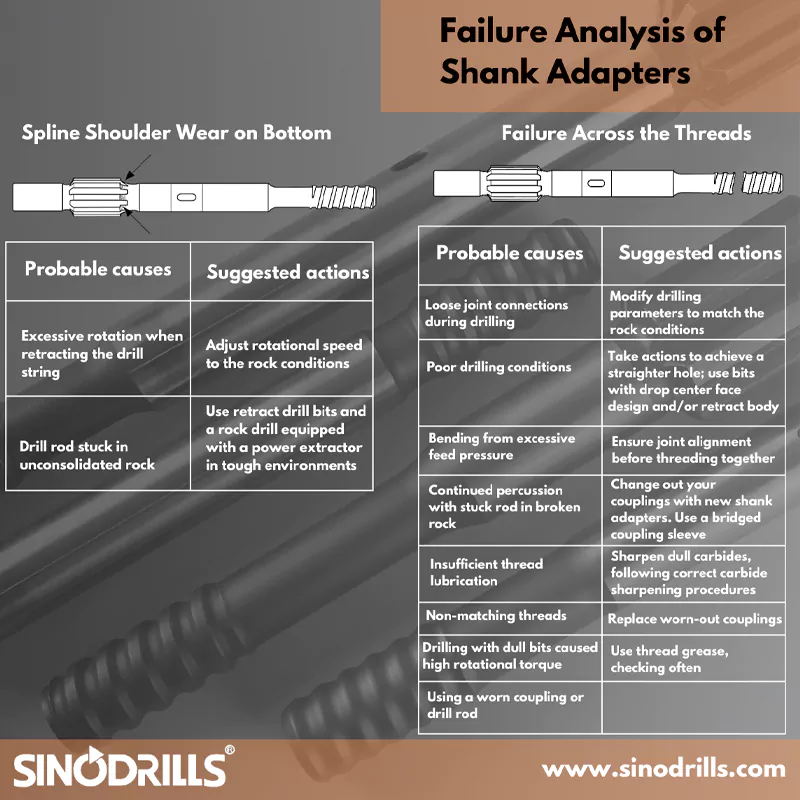

3. Spline shoulder wear on bottom

Probable causes:

– Excessive rotation when retracting the drill string

– Drill rod stuck in unconsolidated rock

Suggested actions:

– Adjust rotational speed to the rock conditions

– Use retract drill bits and a rock drill equipped with a power extractor in tough environments

4. Failure Across the Threads

Probable causes:

– Loose joint connections during drilling

– Poor drilling conditions

– Bending from excessive feed pressure

– Continued percussion with stuck rod in broken rock

– Insufficient thread lubrication

– Non-matching threads

– Drilling with dull bits caused high rotational torque

– Using a worn coupling or drill rod

– Hole deviation

Suggested actions:

– Modify drilling parameters to match the rock conditions

– Take actions to achieve a straighter hole; use bits with drop center face design and/or retract body

– Ensure joint alignment before threading together

– Change out your couplings with new shank adapters. Use a bridged coupling sleeve

– Sharpen dull carbides, following correct carbide sharpening procedures

– Use thread grease, checking often

– Replace worn-out couplings.

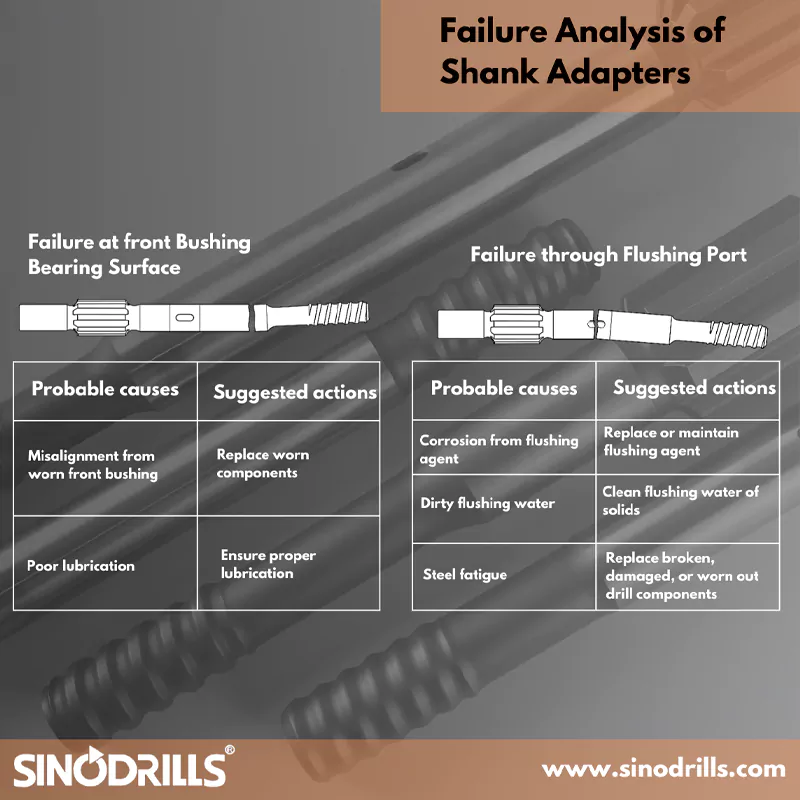

5. Failure at Front Bushing Bearing Surface

Probable causes:

– Misalignment from worn front bushing

– Poor lubrication

Suggested actions:

– Replace worn components

– Ensure proper lubrication

6. Failure through Flushing Port

Probable causes:

– Corrosion from flushing agent

– Dirty flushing water

– Steel fatigue

Suggested actions:

– Replace or maintain flushing agent

– Clean flushing water of solids

– Replace broken, damaged, or worn out drill components

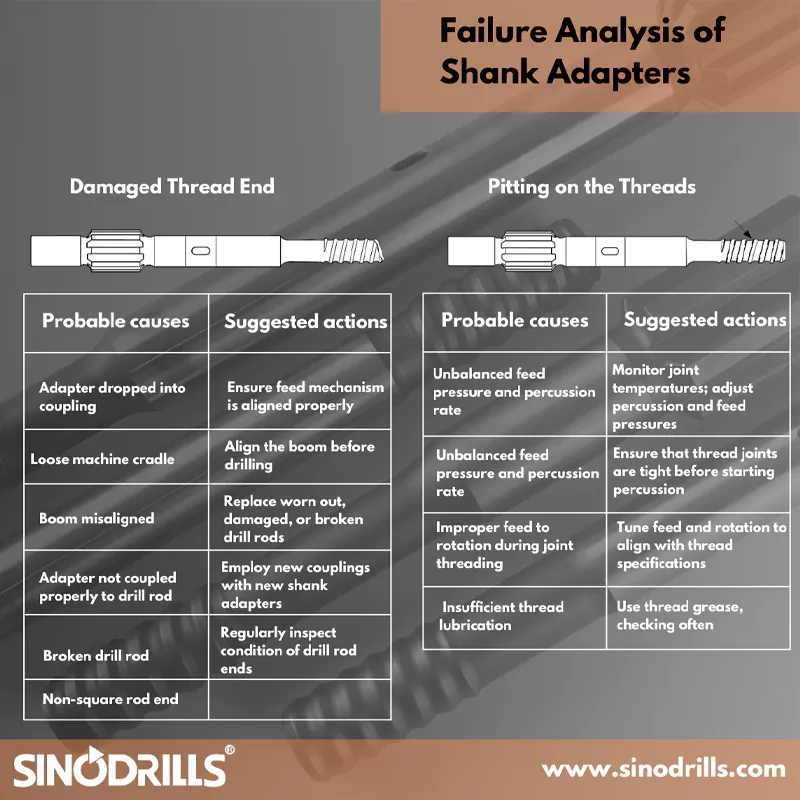

7. Damaged Thread End

Probable causes:

– Adapter dropped into the coupling

– Loose machine cradle

– Boom misaligned

– Adapter not coupled properly to the drill rod

– Broken drill rod

– Non-square rod end

Suggested actions:

– Ensure the feed mechanism is aligned properly

– Align the boom before drilling

– Replace worn-out, damaged, or broken drill rods

– Employ new couplings with new shank adapters

– Regularly inspect the condition of drill rod ends

8. Pitting on the threads

Probable causes:

– Unbalanced feed pressure and percussion rate

– Drilling with loose thread joints

– Improper feed to the rotation during joint threading

– Insufficient thread lubrication

Suggested actions:

– Monitor joint temperatures; adjust percussion and feed pressures

– Ensure that thread joints are tight before starting percussion.

– Tune feed and rotation to align with thread specifications

– Use thread grease, checking often