Choosing the Right Insert for Rock Formation is essential for achieving efficient drilling performance. Selecting the right insert type helps reduce wear, improve penetration rates, and extend bit life. Different rock formations demand different inserts, and understanding these variations ensures cost-effective drilling operations.

When drilling through soft, medium, or hard formations, using the proper insert maximizes productivity and minimizes downtime. Each insert type is engineered to handle specific challenges like abrasiveness, compressive strength, and fracture toughness of rocks. By learning how inserts work with formations, drillers can achieve optimal results in diverse conditions.

What are Rock Drill Bit Inserts?

Rock drill bit inserts are specialized cutting elements mounted on roller bits or button bits to crush, cut, and penetrate rock formations during drilling. They are typically made from durable materials like tungsten carbide, engineered to withstand extreme pressure, abrasion, and impact. Inserts play a crucial role in determining drilling efficiency, bit life, and penetration rate.

Different insert shapes and grades are designed for various rock hardness and conditions. Conical inserts, for example, perform well in hard formations, while chisel or spherical inserts are better suited for medium or softer rocks. By selecting the correct insert type, drillers can improve performance, reduce costs, and ensure consistent results across drilling operations.

Roller Drill Bit Insert Types

Roller drill bit inserts are engineered to handle varying rock hardness and formations. Each insert type is designed to provide maximum penetration, durability, and efficiency under specific conditions. From soft to ultra-hard formations, selecting the right insert ensures consistent drilling performance, lower operational costs, and extended bit service life.

Chisel Insert

Chisel inserts are designed for soft rock formations ranging between 100–120 MPa. Their flat, sharp edges allow for efficient cutting and high penetration rates in softer materials. They reduce torque while drilling, which helps in maintaining stability and smoother operations without excessive stress on equipment.

These inserts are commonly used in shallow drilling operations where speed is prioritized. By offering a balance of efficiency and durability, chisel inserts minimize wear and ensure consistent performance. They are best suited for formations that do not generate excessive heat or abrasion during drilling.

Conical Insert

Conical inserts are ideal for medium rock formations with compressive strengths of 120–140 MPa. Their pointed design allows for effective penetration into moderately hard rocks while reducing wear on the cutting edge. They are a versatile choice, providing a mix of penetration and durability.

Drillers often choose conical inserts for operations requiring adaptability across varying conditions. Their structure helps distribute stress evenly, preventing premature insert breakage. Conical inserts deliver reliable results in construction, mining, and energy projects where medium-hard formations are encountered.

Ballistic Insert

Ballistic inserts are specially engineered for hard rock formations ranging from 130–180 MPa. Their sharp, protruding design provides fast penetration, making them highly efficient in demanding drilling tasks. They are best suited for high-impact drilling where breaking through hard surfaces is critical.

These inserts deliver high drilling speed but may wear faster under extremely abrasive conditions. They are widely used in mining and quarrying, where hard and abrasive formations are common. Ballistic inserts balance penetration with manageable wear, providing excellent results in controlled conditions.

Spherical Insert

Spherical inserts are the strongest option, designed for ultra-hard rock formations with strengths between 150–250 MPa. Their rounded shape ensures maximum durability and resistance to breakage under extreme pressure. Though they penetrate slower than other inserts, they excel in longevity and reliability.

These inserts are ideal for drilling in highly abrasive and fractured formations. They provide consistent performance and resist wear even in the most challenging geological environments. Spherical inserts are preferred when durability outweighs penetration rate, making them essential in critical drilling projects.

Here is the table showing you the different types of roller cone drill bit inserts.

| Insert Type | Rock Formation | Strength Range (MPa) | Features | Applications |

|---|---|---|---|---|

| Chisel | Soft | 100–120 | Flat cutting edge, fast penetration | Shallow drilling, soft formations |

| Conical | Medium | 120–140 | Pointed shape, balanced durability | Construction, mining, energy projects |

| Ballistic | Hard | 130–180 | Sharp protrusions, fast penetration | Mining, quarrying, hard formations |

| Spherical | Ultra-hard | 150–250 | Rounded, high durability | Abrasive and fractured formations |

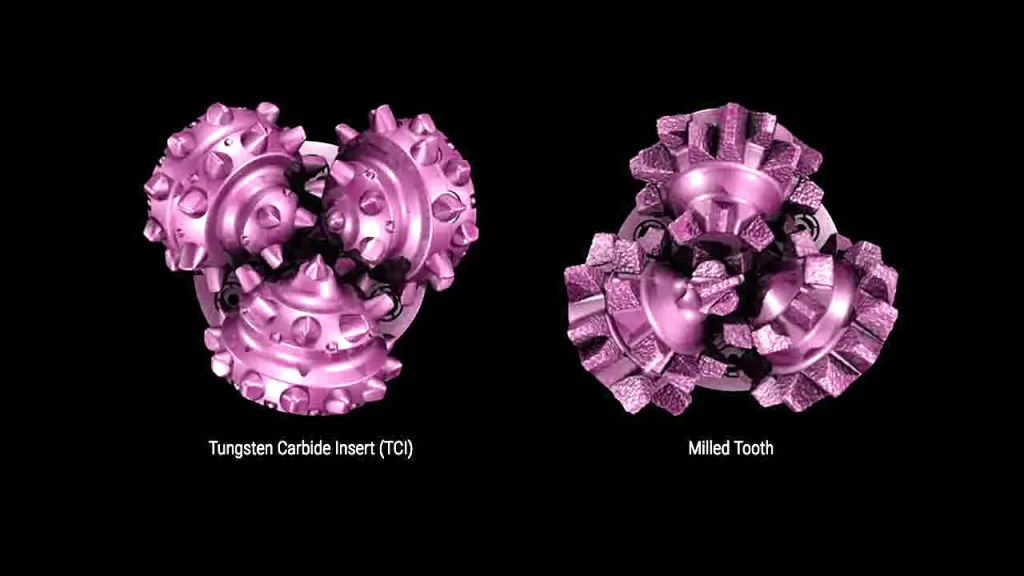

Milled Tooth Bit vs Insert Bit

Milled tooth bits and insert bits are two primary types of roller drill bits used in rock drilling. Each type has unique cutting mechanisms, durability, and efficiency, making them suitable for specific rock formations and drilling conditions. Choosing the right bit ensures optimal performance and cost-efficiency.

Milled Tooth Bit

Milled tooth bits feature steel teeth directly machined from the bit body. These teeth gradually wear down, providing a consistent cutting action. They are ideal for softer to medium-hard formations, allowing fast penetration rates and relatively low drilling costs. We provide milled tooth bits for a variety of drilling applications.

These bits are easier to maintain and can be refurbished by re-machining the teeth. Their simple design reduces the risk of mechanical failure under moderate loads. However, they are less effective in very hard or abrasive rock, where tooth wear can significantly reduce efficiency.

Insert Bit

Insert bits use tungsten carbide inserts embedded into the bit body. These inserts offer extreme hardness and wear resistance, enabling drilling through hard and abrasive formations. We supply insert bits suitable for both soft and very hard rocks, ensuring long-lasting performance.

Insert bits provide stable drilling with lower wear rates, making them cost-effective in the long term for tough formations. While initial costs are higher than milled tooth bits, their durability and reduced maintenance often offset this, especially in hard rock operations.

| Aspect | Milled Tooth Bit | Insert Bit |

|---|---|---|

| Cutting Mechanism | Steel teeth machined from bit body | Tungsten carbide inserts embedded |

| Formation Suitability | Soft to medium-hard rocks | Medium to very hard rocks |

| Durability & Wear | Moderate, wears faster | High, resists wear |

| Maintenance | Can be refurbished by re-machining | Limited, inserts may need replacement |

| Cost Efficiency | Lower initial cost | Higher initial cost, lower long-term |

Conclusion

In conclusion, understanding roller drill bit insert types is key to successful drilling across varied geological conditions. Choosing the right insert minimizes equipment strain, enhances drilling speed, and lowers operational costs. Careful selection allows drillers to achieve consistent results, making operations more efficient and reliable in the long run.

We encourage drillers and contractors to evaluate insert designs carefully before selecting bits for specific formations. Whether it’s hard, medium, or soft rock, matching the right insert ensures both performance and durability. Knowledge-backed decisions help avoid costly replacements while maximizing drilling efficiency for different applications.

If you are searching for reliable, high-quality inserts, get wholesale rock drill bits from our Sinodrills. We provide a wide range of roller drill bit inserts engineered for different formations. With proven performance, durability, and wholesale pricing, our products support your drilling projects with the efficiency and reliability you need.