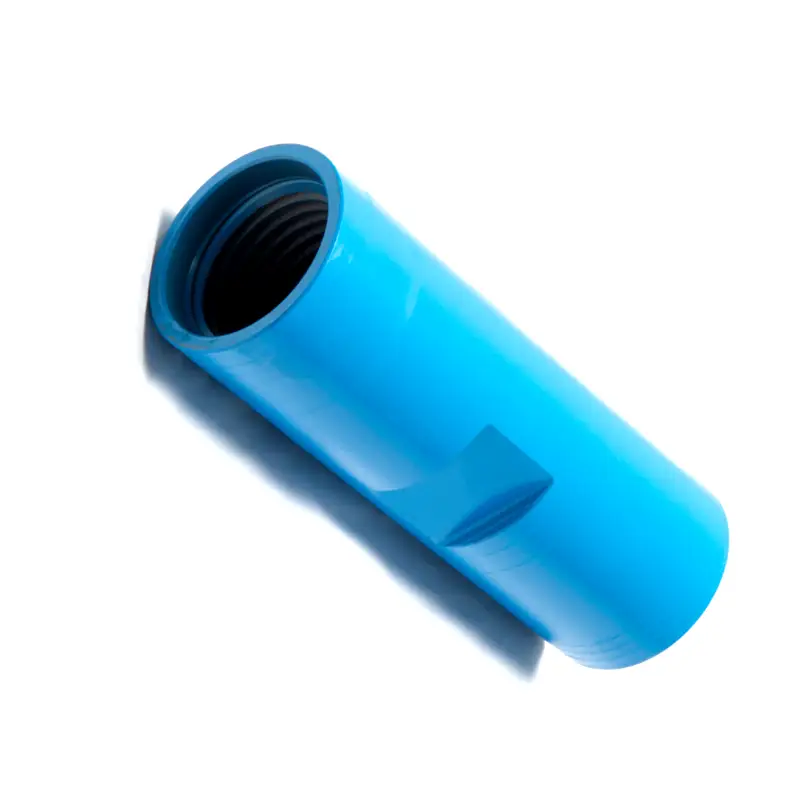

Custom Semi Bridge Coupling Sleeve Manufacturer in China

We specialize in high-performance Full Bridge Coupling Sleeves for maximum drilling rigidity and durability. Featuring continuous internal threading, they ensure solid, metal-to-metal rod contact, eliminating thread creep under extreme torque and percussion. Choose our robust sleeves for a consistently secure, jam-free connection in the most demanding rock drilling environments, maximizing energy transfer.

Sinodrills - Your Trusted Semi Bridge Coupling Sleeve Manufacturer from China

We offer superior quality rock drilling tools. Our Semi Bridge Sleeves feature a central unthreaded stop, ensuring precise rod-butting for effective energy transfer and quick make-up/break-out. Rely on our heat-treated, high-torque couplings for reliability and efficiency in all your mining and construction project

Semi Bridge Coupling Sleeve Benefits

Easier Make-up and Break-out: The central, non-threaded “bridge” section prevents over-screwing of the drill rods. This significantly speeds up the process of adding or removing rods, improving overall operational efficiency and reducing downtime on site.

Precise Rod-Butting: The unthreaded center acts as a stop, ensuring the ends of the two connecting rods precisely butt together. This critical metal-on-metal contact is vital for optimal energy transfer and tool string integrity.

Suitable for High-Torque Machines: The design, which includes the central stop, makes these couplings highly effective for use with powerful, high-torque drilling equipment. They manage rotational stress well, particularly in trapezoidal (T) and rope (R) threads.

Semi Bridge Coupling Sleeve Applications

Underground Mining: Links drill rods for face drilling and bolting in tunnels, allowing quick make-up/break-out to boost operational efficiency.

Civil Construction: Used for foundations, infrastructure, and site prep, offering a strong connection and faster rod changes in diverse ground conditions.

Bench Drilling/Quarrying: Ideal for creating blast holes in quarries using high-torque percussive drills, being the most popular type for Rope (R) and Trapezoidal (T) threads.

Shank Adapter Connection: Joins the drill rig’s shank adapter to the first rod, ensuring efficient transmission of all percussive and rotational energy down the string.

Customize Your Desired Semi Bridge Coupling Sleeve

Thread Type and Size

We precisely machine the internal threads to match your specific drill rods and shank adapter threads (e.g., R32, T38, T45, T51). This ensures a perfect, tight fit for optimal energy transmission from the hammer, preventing tool string failure and maximizing penetration rates.

Material Grade and Heat Treatment

We select alloy steel and apply customized heat treatments, including carburization, based on your rock formation’s hardness and abrasiveness. This process enhances surface hardness and core toughness, significantly boosting resistance to shock and wear for longer life.

Length and Diameter

We adjust the coupling sleeve’s overall length and outside diameter to fine-tune energy wave transmission and accommodate your equipment’s limits. A customized length helps maintain the optimal rod-to-rod contact geometry, which is crucial for efficient power transfer and minimizing thread fatigue.

Corrosion Protection/Coating

We apply specialized coatings or surface finishes to protect the sleeve from environmental corrosion and rust, especially for underground or wet drilling. This defense against harsh drilling fluids and moisture maintains thread integrity and facilitates easier make-up and break-out over the tool’s lifespan.

All-in-one Semi Bridge Coupling Sleeve Solutions for Your Project

We offer reliable semi bridge coupling sleeve solutions engineered for top-hammer drilling efficiency. Featuring the unthreaded central stop, our sleeves ensure a perfect, butt-to-butt rod connection, optimizing energy transfer while allowing for quick make-up and break-out. Choose our quality sleeves for superior operational convenience and longevity in high-torque applications.