Custom DTH Hammer With Foot Valve Manufacturer in China

We offer DTH hammers with foot valves, designed to deliver superior drilling performance in mining, construction, and quarrying projects. Featuring efficient air circulation and enhanced impact energy, our hammers ensure faster penetration, reduced bit wear, and longer service life. Trust us for reliable, durable, and high-performance DTH hammer solutions.

Sinodrills - Your Trusted DTH Hammer With Foot Valve Manufacturer from China

Your trusted DTH hammer with foot valve manufacturer from China, we specialize in producing durable, and efficient drilling tools. Our hammers deliver superior impact energy, faster penetration, and longer service life, making them ideal for mining, construction, and quarrying projects. Rely on us for reliable, performance-driven DTH hammer solutions at competitive prices.

DTH Hammer With Foot Valve Benefits

Improved Airflow Control The foot valve precisely regulates pressurized air entering the hammer body. This maintains the necessary pressure to achieve maximum impact force on the drill bit, optimizing rock fragmentation efficiency.

Enhanced Energy Transfer By regulating the air flow, the foot valve ensures effective energy delivery. This results in faster penetration rates and more efficient operation, reducing overall drilling time and resource consumption significantly.

Valveless Air Distribution Foot valve designs often facilitate more reliable valveless air distribution within the hammer structure. This design simplifies the internal mechanism, leading to fewer points of failure and superior long-term reliability.

Reduced Internal Wear The control over airflow and pressure maintenance helps to protect internal components. This minimizes wear on critical parts like the piston, extending the overall service life of the DTH hammer assembly.

Easier Maintenance Structure Hammers with foot valves often feature a simpler, more robust internal structure with fewer moving parts. This makes the hammer easier to disassemble, inspect, and maintain, reducing downtime and repair costs.

DTH Hammer With Foot Valve Applications

Water Well Drilling: The foot valve prevents water and cuttings from flowing back up into the hammer when the air supply is momentarily stopped, increasing efficiency.

Mineral Exploration: Ideal for deep drilling in fractured or broken ground formations, ensuring better sample recovery and cleaner borehole walls during operation.

Geothermal Drilling: Effective in high-temperature environments, as the foot valve maintains optimal operational pressure within the hammer despite water presence.

Foundation Drilling (Piling): Essential for drilling anchor holes and micro-piles in unstable or loose soil conditions, minimizing the risk of hole collapse.

Quarrying and Mining: Used for production blastholes where fractured or heavily jointed rock is common, leading to straighter holes and better fragmentation results.

Construction Blasting: Suitable for controlled blasting operations in urban or sensitive areas, ensuring precision drilling and reduced vibration levels nearby.

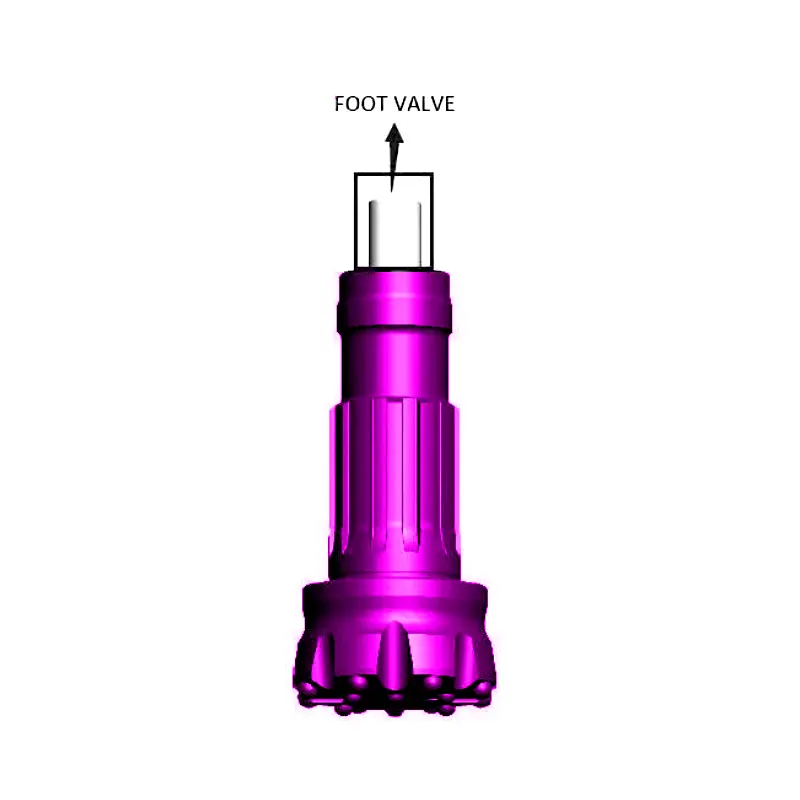

Foot Valve of DTH Hamer

Optimizes Air Consumption: The foot valve efficiently controls the flow of compressed air into the hammer’s piston chamber, minimizing wasted air and improving the overall energy efficiency of the drilling operation.

Improves Impact Energy: By creating a sealed chamber, the valve ensures maximum pressure is built up behind the piston, leading to a more forceful and consistent strike for better penetration and faster drilling rates.

Reduces Piston Wear: It prevents cuttings and debris from entering the hammer mechanism from the bottom, significantly extending the service life of the piston and other internal components by reducing abrasion.

Enhances Hole Cleaning: A correctly functioning foot valve contributes to better air distribution for flushing, effectively removing drill cuttings from the borehole, which prevents re-drilling and maintains high ROP (Rate of Penetration).

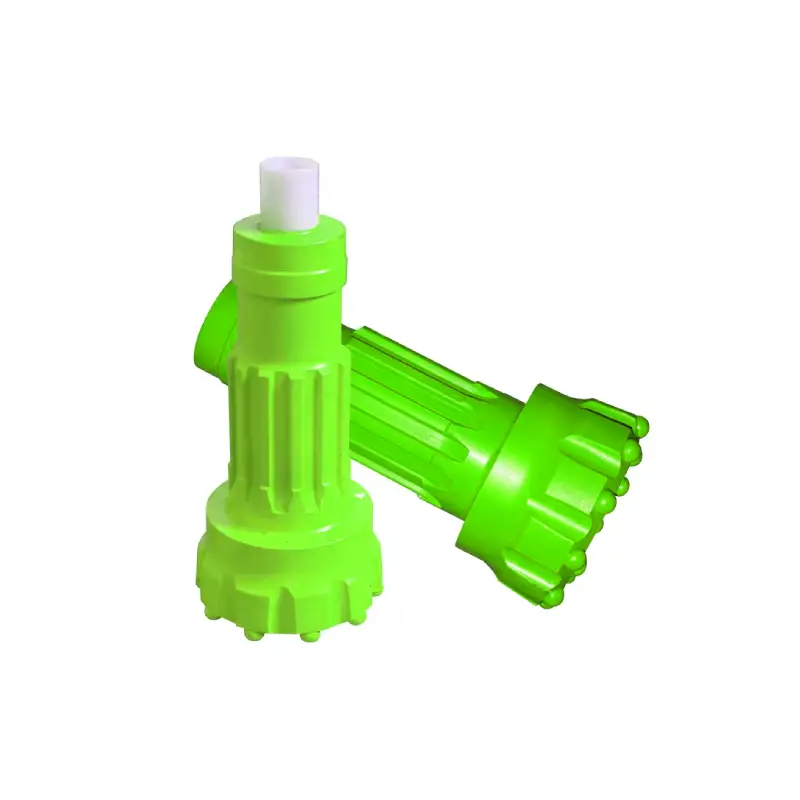

Various DTH Hammer With Foot Valve

button drill bit with foot valve

We offer premium DTH button drill bits specifically designed for seamless integration with a foot valve assembly. This combination ensures optimized airflow control, maximum impact energy transfer, superior hole cleaning, and significantly extended bit lifespan. Our durable, high-performance bits deliver faster penetration rates and lower cost-per-meter in demanding drilling environments, providing unmatched productivity for your operations.

DTH drill bit with foot valve

We proudly offer a selection of DTH drill bits integrated with a foot valve, designed to maximize your drilling efficiency and tool longevity. This specialized combination significantly improves impact energy transfer, ensures superior hole cleaning by preventing debris backflow, and reduces air consumption. Choose our advanced bits for faster penetration rates and extended service life in various rock formations.

rock drill bit with foot valve

We offer premium Down-The-Hole (DTH) rock drill bits with foot valves (also known as exhaust tubes) designed for maximum efficiency. These components are vital for optimizing air consumption, maintaining impact pressure for faster penetration, and effectively clearing rock cuttings from the borehole. We stock a comprehensive range compatible with all major DTH hammer shanks, ensuring reliable performance and extended operational life.

skirt drill bit with foot valve

We offer high-performance skirt drill bits featuring an integrated foot valve design. This combination ensures superior flushing and hole cleaning by preventing cuttings backflow, leading to faster penetration rates and extended bit life. Our bits deliver optimized drilling efficiency in various rock formations for DTH applications.

speed drilling drill bit with foot valve

We offer high-performance Down-The-Hole (DTH) drill bits specifically designed for speed drilling applications. These bits feature a specialized foot valve design that is crucial for maximizing performance by ensuring optimal compressed air distribution, leading to faster penetration rates and efficient flushing of cuttings, which is ideal for mining, construction, and water well projects.

flat face drill bit with foot valve

We offer flat face DTH drill bits with Foot Valves for Down-The-Hole drilling. The flat face design excels in hard and abrasive rock formations, providing excellent durability and effective breaking power. Coupled with a foot valve, this combination ensures optimal air efficiency, maximum impact energy transfer, and superior flushing for reduced wear and higher penetration rates.

QL series drill bit with foot valve

We offer premium QL series DTH drill bits featuring a robust foot valve design. These bits deliver superior impact energy, ensuring faster penetration and exceptional performance in hard rock conditions. Their construction prevents backflow contamination, optimizes air usage for efficient hole cleaning, and significantly extends the tool’s lifespan. We supply various sizes for all major QL hammers.

customized drill bit with foot valve

We specialize in providing customized drill bits with foot valves tailored to your specific drilling needs. Our expertise ensures optimal compatibility with your DTH hammer, matching the exact shank and face design for maximum performance in your geological conditions. We offer durable, high-quality components to enhance your penetration rate and tool life.

DTH drill bit with foot valve

We offer high-performance Down-The-Hole (DTH) drill bits featuring an integrated foot valve. This design is crucial for optimizing air distribution, maximizing impact energy transfer, and ensuring superior hole cleaning by preventing rock debris backflow. Our specialized bits guarantee faster penetration rates and prolonged service life, especially in challenging, wet drilling conditions.

Customize Your Desired DTH Hammer With Foot Valve

Face Design Profile

We can customize the bit face profile to perfectly suit the rock formation you are drilling. Options include Concave for better hole straightness, Convex for maximum penetration speed in soft-to-medium rock, and Flat for abrasive or hard rock, ensuring the most efficient energy transfer from the foot valve-equipped hammer to the rock face.

Tungsten Carbide Button Configuration

We offer various arrangements of carbide buttons to match rock hardness and abrasiveness. This involves specifying the number, size, and shape (e.g., spherical for maximum life, ballistic for faster drilling) of the inserts, which directly impacts the bit’s aggression, wear resistance, and ability to fracture the formation efficiently.

Flushing Hole and Groove Optimization

We meticulously adjust the size and position of the flushing holes and grooves on the bit face. This ensures the high-pressure air and cuttings are optimally evacuated from the bottom of the hole, preventing re-drilling of material and bit-jamming. Proper flushing is essential for maintaining the high rate of penetration provided by the foot valve.

Material and Heat Treatment

We select specific grades of high-strength alloy steel for the bit body and fine-tune the heat treatment process, including carburization depth and surface hardness. This customization maximizes the core toughness and gauge button retention, providing superior resistance to fatigue and abrasive wear in the most challenging drilling environments.

what is foot valve for Drill Bits?

The “foot valve,” often referred to as a blow tube or exhaust tube, is a crucial internal component used primarily in Down-The-Hole (DTH) hammer drilling systems that utilize drill bits with this specific feature.

It is a mechanical part positioned at the bottom of the DTH hammer, typically fitted inside the shank end of the drill bit. Its main function is to control the flow of highly pressurized air within the hammer body. By directing the compressed air, it ensures the piston operates correctly and efficiently, delivering maximum impact energy directly to the bit face to fracture the rock, which is especially important for maintaining a high penetration rate in hard rock drilling applications.

what are the differences between drill bits with Foot valve and without foot valve?

The key differences between Down-The-Hole (DTH) drill bits with a foot valve and those without one lie primarily in the DTH hammer design they are paired with, which affects drilling efficiency, complexity, and maintenance.

Drill bits with a foot valve (also called a blow tube) operate with older, valved DTH hammers that have more internal components. The foot valve is a dedicated part that fits into the bit shank to mechanically control the air flow for the hammer’s piston cycle.

Hammer Complexity and Maintenance: The combination of a foot valve bit and a valved hammer means more internal parts that can fail, increasing the complexity of maintenance and raising the potential for wear and tear.

Vulnerability to Damage: The foot valve itself is often made of plastic, making it susceptible to breaking from excessive heat, physical impact, or stress, which leads to immediate drilling downtime.

Air Consumption Efficiency: This traditional system is generally less efficient in air usage because some compressed air energy is lost during the valve’s mechanical reversal action, consuming more power per meter drilled.

Drill bits without a foot valve are designed for use with modern valveless DTH hammers, which feature a simpler internal design where air distribution is controlled by the piston itself. This valveless system represents a significant evolution in DTH technology.

Drilling Speed and Frequency: Valveless hammers with these bits typically achieve a higher impact frequency and offer a 15-30% faster penetration rate by more efficiently utilizing the compressed air’s expansion energy.

System Reliability and Durability: By eliminating the delicate foot valve, the system removes a common point of failure and makes the overall hammer structure more reliable and robust, simplifying servicing and extending operational life.

Energy and Cost Savings: The design allows for a lower air and diesel consumption, as the more direct air-distribution system reduces energy loss, ultimately lowering the operational costs over the drilling lifespan.

what are benefits of drill bits with foot valve?

Drill bits that incorporate a foot valve, also known as a blow tube, are integral to the operation of a traditional valved Down-The-Hole (DTH) hammer. While newer valveless designs offer advancements, the foot valve system provides distinct benefits, especially for specific drilling conditions and operational preferences.

Effective Pressure Conservation: The foot valve acts as a check mechanism to efficiently maintain back pressure within the hammer’s air chamber when the piston cycles. This is particularly helpful in situations where the drilling area may contain water, preventing water from entering the hammer and slowing down operation.

Positive Airflow Directional Control: The mechanical action of the valve ensures precise regulation of compressed air as it enters and exhausts the hammer. This directional control ensures the maximum impact energy is consistently transferred directly from the piston to the drill bit for effective rock fragmentation.

Compatibility with Older Equipment: Foot-valved bits are crucial for compatibility with the large installed base of older valved DTH hammer models still in use globally. This allows operators to continue utilizing existing, durable equipment without the substantial capital investment required for a full valveless system upgrade.

Simple Piston Design and Longevity: The valved hammer system that uses these bits allows for a simpler, more robust piston design with fewer complex air ports compared to valveless systems. This design simplicity can contribute to a long service life for the piston itself, resisting high-pressure wear.

what are uses of drill bits with foot valve?

Drill bits equipped with a foot valve are primarily used in conjunction with valved Down-The-Hole (DTH) hammers for various percussive drilling applications.

The foot valve’s design, which assists in air management and water exclusion, makes these bits suitable for specific conditions within the mining, construction, and water well industries.

Water Well and Geothermal Drilling: The foot valve’s ability to minimize water backflow into the hammer’s piston chamber is highly advantageous when drilling in water-bearing or wet geological formations. This keeps the hammer dry and maintains its maximum impact energy for consistent and efficient deep hole drilling operations.

Mining and Quarry Blast Holes: These bits are widely employed in creating the deep, straight blast holes required in quarrying and open-pit mining of hard, abrasive rock types. Their use with valved DTH hammers ensures a high energy transfer rate, leading to effective rock fragmentation and rapid penetration.

Foundation and Construction Piling: In civil engineering and construction, foot-valved bits are utilized for drilling anchor and piling holes for infrastructure projects, especially where the ground consists of hard rock layers. Their compatibility with existing DTH rigs is crucial for these widespread construction applications.

Environments with Water Ingress: The bits are often preferred in drilling operations where there is an anticipated risk of water entering the drill hole, which could flood a valveless hammer. The simple mechanism of the foot valve helps to maintain a clean air channel and proper hammer function.

Send Your Inquiry Now

All-in-one DTH Hammer With Foot Valve Solutions for Your Project

Our DTH hammer with foot valve solutions guarantee high-performance drilling for your project. The foot valve maximizes impact energy, ensuring rapid penetration in hard rock formations. It also provides superior back-pressure resistance and efficient flushing, making it ideal for deep holes, wet conditions, and minimizing downtime in quarrying, mining, and water well applications.