Tricone drill bits are indispensable tools in oil, gas, and mining, known for their versatility across various rock formations. They feature three rotating cones that effectively crush, chip, and grind rock. Understanding their mechanical action is key to optimizing drilling performance and efficiency in complex geological environments.

This blog post will demystify how these robust tools function at the bottom of the wellbore. We’ll explore the design of the roller cones and cutting structures, illustrating how the interplay of rotation and weight delivers unparalleled penetration rates and reliability in your drilling operations.

What are Tricone Drill Bits

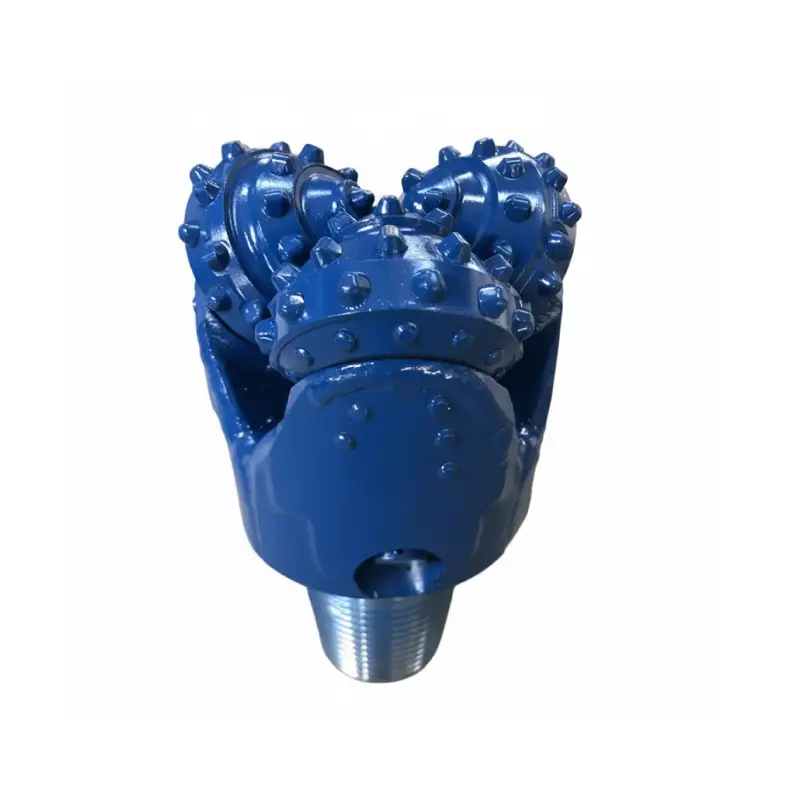

A Tricone drill bit is a type of rotary drilling tool characterized by its head being divided into three primary sections, each featuring a rotating, cone-shaped roller.

These three independent cones are fitted with robust cutting elements, which can be either milled steel teeth or durable tungsten carbide inserts (TCI). As the entire drill string rotates, the cones roll across the bottom of the wellbore, with their teeth continually crushing, chipping, and grinding the rock, a highly efficient mechanism for breaking up various geological formations.

How Tricone Drill Bits Work?

Tricone drill bits operate by combining three distinct mechanical actions to efficiently break and remove rock at the bottom of the wellbore. This simultaneous crushing, chipping, and scraping action allows them to penetrate a vast range of soft, medium, and hard geological formations. The overall effectiveness is determined by the applied weight-on-bit (WOB) and the rotary speed (RPM).

The primary drilling mechanisms utilized by these tools are:

- Impact Crushing The heavy downward force (WOB) transmitted through the drill string presses the cones’ teeth into the rock, which is then pulverized. This is the dominant action in harder, more brittle formations, causing the rock to fracture and crumble under high compressive stress.

- Gouging and Scraping The three cones are mounted with a slight offset from the bit’s central axis, ensuring they do not purely roll. This slipping motion generates a scraping action between the teeth and the rock surface, effectively shearing and tearing away softer formation material.

- Rock Chip Removal Drilling fluid (mud, water, or air) is jetted through nozzles on the bit face. This fluid stream cools the cones, cleans the space between the cutting structures, and most crucially, lifts the pulverized rock cuttings out of the borehole and to the surface.

Types of Tricone Drill Bits

Tricone drill bits are primarily classified by their cutting structure, which determines the rock formations they are best suited to drill. The two main types, Milled-Tooth and Tungsten Carbide Insert (TCI), offer different balances of cost, durability, and drilling speed, allowing operators to match the tool precisely to the geological challenge.

The main types based on cutting structure are:

- Milled-Tooth (MT) Bits: These bits feature long, aggressive teeth that are milled directly from the steel cone. Designed for soft to medium, non-abrasive formations like shale and clay, they maximize the gouging and scraping action for a high rate of penetration (ROP) but wear down quickly in hard rock.

- Tungsten Carbide Insert (TCI) Bits: TCI bits utilize extremely hard tungsten carbide “buttons” pressed into the cones. The inserts are highly durable and wear-resistant, making them the superior choice for drilling in medium-hard to extremely hard and abrasive rock types, relying mainly on a crushing mechanism.

Why Choose Our Tricone Drill Bits?

Selecting our tricone drill bits is a decision based on proven performance, superior material quality, and unmatched versatility across diverse geological environments. Their robust design, featuring three independently rolling cones, is specifically engineered to maximize rock destruction through crushing and chipping, leading to reliable and efficient drilling in soft, medium, and hard formations.

Exceptional Versatility: Tricone bits are adaptable across the entire spectrum of rock formations, unlike specialized tools. This makes them ideal for drilling through soft shales, interbedded layers, and even very hard, abrasive granite without needing a bit change.

Superior Durability and Longevity: Our bits are constructed with high-grade alloy steel bodies and advanced sealed journal bearings. When combined with Tungsten Carbide Inserts (TCI), this material technology provides a significantly extended service life and superior resistance to wear in challenging, high-pressure, and high-temperature downhole conditions.

Consistent High Rate of Penetration (ROP): The triple-cone design maximizes rock failure by crushing and chipping the formation with every rotation. This synergistic action maintains a stable and predictable drilling speed, reducing non-productive time and ensuring rapid advancement through most strata.

Cost-Effective Drilling Solution: Although initial costs may be higher for TCI models, the extended lifespan and reduced trip time for bit changes result in a lower overall cost per foot drilled. This makes our tricone bits an economical choice for both shallow and deep well drilling projects.

Conclusion

The power of the tricone bit lies in its mechanical advantage: three independent cones that work in tandem to break rock through crushing and shearing. This design minimizes wear, maximizes penetration, and provides the necessary stability for straight, deep wellbores. Whether you’re in a soft shale or hard granite, the right tricone selection ensures optimal drilling speed and reduced time spent changing out the bottom hole assembly (BHA).

Understanding the relationship between weight-on-bit (WOB), rotary speed, and the bit’s cutting structure is paramount to cost-effective drilling. By selecting the correct insert type (TCI) or milled teeth, you ensure the tricone bit is perfectly matched to the formation’s hardness, dramatically extending its lifespan and boosting the overall drilling rate of penetration (ROP).

When your project demands reliability and performance, choose Sinodrills. We offer a comprehensive range of wholesale tricone drill bits, including specialized TCI and milled tooth designs, manufactured to the highest API standards. Contact Sinodrills today to secure durable, high-efficiency bits that cut your drilling time and costs.