CPT (Cone Penetration Testing) drilling is an in-situ geotechnical investigation technique used to determine the engineering properties of soils and delineate soil stratigraphy. Unlike traditional drilling methods that remove soil, CPT involves pushing an instrumented cone into the ground at a controlled rate while recording continuous measurements.

As the cone penetrates the subsurface, sensors within the probe collect data on tip resistance, sleeve friction, and pore water pressure. These real-time measurements provide a detailed and continuous profile of the soil layers and their characteristics with depth. This data is crucial for assessing soil strength, density, and potential behavior under various loading conditions, making it invaluable for foundation design and other geotechnical analyses.

What is CPT Drilling

What does CPT stand for in drilling?

CPT (Cone Penetration Testing) drilling is an in-situ geotechnical investigation technique used to determine the engineering properties of soils and to delineate soil stratigraphy.

It involves pushing an instrumented cone-tipped probe into the ground at a constant rate using hydraulic rams. As the cone penetrates the soil, sensors within the cone continuously measure parameters such as cone tip resistance, sleeve friction, and pore water pressure, providing a detailed and real-time profile of the subsurface conditions without the need for soil sampling and laboratory testing.

What is a CPT Boring?

While “CPT boring” isn’t a standard term, it essentially refers to the process of conducting a Cone Penetration Test (CPT). Instead of traditional drilling methods that remove soil to create a borehole for sampling, CPT involves pushing an instrumented cone-tipped probe directly into the ground.

This continuous pushing action allows for real-time, in-situ measurement of soil properties like tip resistance, sleeve friction, and sometimes pore water pressure, providing a detailed subsurface profile without generating soil cuttings like conventional boring techniques.

How is a Cone Penetration Test Undertaken?

Undertaking a Cone Penetration Test (CPT) is a systematic process that yields valuable in-situ geotechnical data. This efficient method involves specialized equipment and precise procedures to continuously assess subsurface soil characteristics.

Here’s how a CPT is typically conducted:

CPT Procedure

A Cone Penetration Test (CPT) is conducted to assess subsurface soil conditions by pushing an instrumented cone into the ground. This process provides valuable data for geotechnical engineering analysis.

Equipment Setup and Cone Preparation

The process begins with the preparation of the CPT equipment. This typically involves a specialized hydraulic pushing rig, which can be truck-mounted or track-mounted, providing the necessary force to advance the cone.

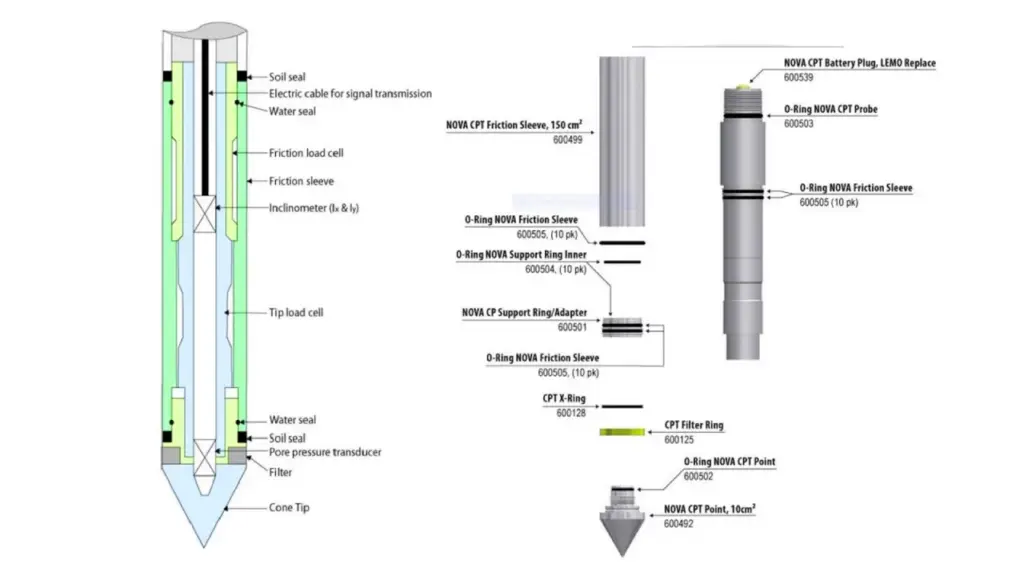

The cone itself is a precisely engineered instrument, usually made of steel, containing electronic sensors to measure soil resistance, friction, and pore water pressure. The cone is attached to a series of rods that will be pushed into the ground. Calibration of the cone’s sensors is crucial to ensure the accuracy of the measurements.

Penetration and Data Acquisition

The core of the CPT involves pushing the cone into the soil at a controlled, constant rate, typically around 2 cm/s. The hydraulic pushing rig provides the force to advance the cone and rods. As the cone penetrates the soil, the sensors continuously measure the resistance encountered by the cone tip (tip resistance) and the friction along the cone sleeve (sleeve friction).

In some cases, pore water pressure is also measured. These measurements are transmitted to a data acquisition system at the surface in real-time, where they are recorded and displayed.

Data Interpretation and Reporting

The data collected during the penetration is then analyzed by geotechnical engineers. The measurements of tip resistance, sleeve friction, and pore water pressure (if available) are used to infer soil type, strength, and other relevant properties.

Empirical correlations and established geotechnical principles are applied to interpret the data. The results are typically presented in a report that includes graphs of the measured parameters versus depth, soil stratigraphy, and estimated soil properties. This report provides crucial information for foundation design, settlement analysis, and other geotechnical engineering applications.

CPT Geotechnical Drilling

CPT (Cone Penetration Testing) geotechnical drilling is a method used to investigate subsurface soil conditions by pushing an instrumented cone-tipped probe into the ground. Unlike traditional drilling methods that extract soil samples, CPT provides continuous, in-situ measurements of soil properties as the cone is advanced. This allows for a rapid and detailed assessment of the soil profile and its engineering characteristics.

Key aspects of CPT geotechnical drilling include the use of a specialized hydraulic pushing rig to advance the cone at a constant rate. Sensors within the cone measure parameters such as cone tip resistance (qc), sleeve friction (fs), and often pore water pressure (u).

These real-time measurements are recorded and used to infer soil type, strength, and other relevant geotechnical parameters without the need for sample retrieval and laboratory testing, offering efficiency and cost-effectiveness for many projects.

- In-Situ Testing: CPT provides direct, real-time measurements of soil properties in their natural state, minimizing disturbance compared to traditional drilling and sampling methods.

- Continuous Profiling: The continuous penetration of the cone allows for a detailed and high-resolution profile of the subsurface soil stratigraphy and variability with depth.

- Multiple Parameters: Standard CPT measures cone tip resistance and sleeve friction, while advanced piezocones (CPTu) also measure pore water pressure, providing a more comprehensive understanding of soil behavior.

- Efficiency and Speed: CPT is generally faster and more cost-effective than conventional drilling and sampling, allowing for more data to be collected in a shorter timeframe.

- Versatile Applications: CPT data is utilized in a wide range of geotechnical engineering applications, including foundation design, slope stability analysis, liquefaction assessment, and environmental investigations.

What is the Difference Between SPT and CPT?

While both the Standard Penetration Test (SPT) and the Cone Penetration Test (CPT) are in-situ geotechnical investigation methods, they differ significantly in their execution and the type of data they provide. Understanding these distinctions is crucial for selecting the appropriate test for a given project.

SPT Procedure

The Standard Penetration Test (SPT) involves drilling a borehole to the desired testing depth. A thick-walled split-spoon sampler is then lowered into the borehole and driven into the soil by repeatedly dropping a hammer of a specific weight from a fixed height.

The number of blows required to drive the sampler a specific distance (typically the last 30 cm or 12 inches) is recorded as the SPT N-value. This N-value provides an indication of the soil’s resistance to penetration, which is empirically correlated to various soil properties like density and strength. Soil samples are also retrieved within the split spoon for visual classification and laboratory testing.

CPT Procedure

In contrast, the Cone Penetration Test (CPT) does not require pre-drilling a borehole. Instead, a cone-tipped probe, equipped with electronic sensors, is pushed directly into the ground at a constant rate using hydraulic rams.

As the cone penetrates the soil, it continuously measures the resistance encountered by the cone tip (tip resistance, qc) and the friction along the cone sleeve (sleeve friction, fs). Some CPT probes also measure pore water pressure (u). This continuous data acquisition provides a detailed and high-resolution profile of the subsurface soil stratigraphy and properties in real-time, without retrieving physical samples.

Key Differences

The primary differences lie in the method of penetration, the type of data collected, and the ability to obtain soil samples. SPT is a dynamic test involving hammering and yields disturbed soil samples, while CPT is a static test involving pushing and provides continuous, in-situ measurements of soil resistance and friction.

CPT is generally faster and more cost-effective for characterizing soil profiles and determining parameters in softer soils, offering a higher resolution of data. However, SPT provides actual soil samples for laboratory analysis and is often preferred in denser or coarser soils where penetration with CPT might be limited.

CPT Drilling Applications

CPT drilling is a versatile geotechnical investigation technique with numerous applications across various engineering disciplines. Its ability to provide continuous, real-time subsurface data makes it invaluable for site characterization and informed decision-making. Key application areas include:

- Foundation Design: CPT data is used to determine soil bearing capacity, settlement characteristics, and the identification of suitable bearing layers for various foundation types, including shallow footings and deep piles. The continuous soil profiling aids in optimizing foundation design and predicting structural performance.

- Slope Stability Analysis: By identifying weak zones and potential slip surfaces within soil masses, CPT data contributes to accurate slope stability assessments. Pore water pressure measurements obtained from piezocones (CPTu) are particularly critical in evaluating effective stress conditions and predicting slope behavior under different loading scenarios.

- Liquefaction Assessment: CPT is a widely accepted method for evaluating the potential for soil liquefaction in earthquake-prone regions. Correlations between CPT measurements (tip resistance and sleeve friction) and soil density, fines content, and plasticity allow engineers to assess a soil’s susceptibility to liquefaction under seismic loading.

Beyond these core geotechnical applications, CPT drilling also plays a significant role in other engineering fields, providing crucial subsurface information for diverse projects. These include:

- Environmental Site Assessment: CPT can be equipped with specialized sensors to detect contaminants in the soil and groundwater, allowing for efficient and cost-effective mapping of contamination plumes. This minimizes soil disturbance and reduces the generation of investigation-derived waste.

- Ground Improvement: CPT is used to evaluate the effectiveness of ground improvement techniques such as soil compaction, vibroflotation, and deep mixing. By performing CPT before and after treatment, engineers can quantify the improvement in soil strength and stiffness.

- Pavement Design: CPT data can be correlated with soil resilient modulus and other parameters relevant to pavement performance, aiding in the design of more durable and cost-effective road structures.

- ** трубопроводы and Underground Utilities:** CPT investigations can help identify suitable routes for pipelines and underground utilities by characterizing soil conditions and detecting potential obstructions or unstable zones.

Conclusion

In conclusion, CPT drilling offers a valuable and efficient method for in-situ geotechnical investigation. Its ability to provide continuous, real-time data on soil properties makes it a crucial tool for site characterization and foundation design. Understanding the principles and applications of CPT drilling is essential for successful geotechnical projects.

For those involved in geotechnical investigations, access to reliable drilling tools is paramount. Sinodrills, a drilling tool manufacturer from China, offers a range of wholesale drilling equipment. Partnering with a direct manufacturer can provide cost-effective solutions for your project needs.

By leveraging the benefits of CPT drilling and sourcing quality tools from manufacturers like Sinodrills, geotechnical professionals can enhance the efficiency and accuracy of their subsurface investigations, ultimately contributing to safer and more economical construction projects.