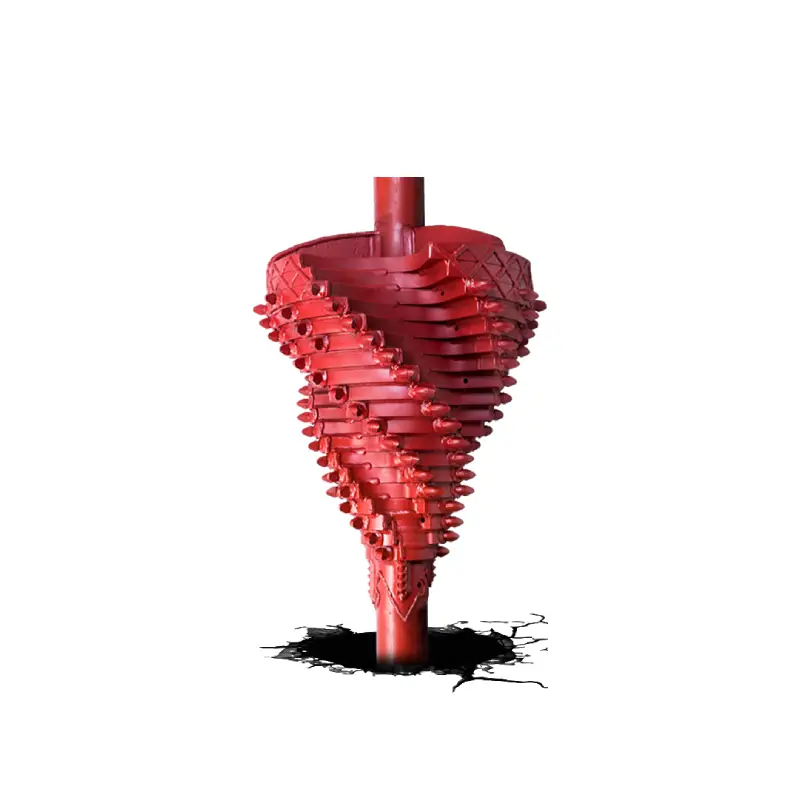

Custom Back Reamer Manufacturer in China

We offer back reamer DTH drill bits designed to stabilize and enlarge boreholes during pull-back, ensuring smooth, precise holes and reducing the risk of collapse. Ideal for unstable or fractured formations, these bits enhance drilling efficiency, improve hole cleanliness, and minimize stuck tool issues. Perfect for mining, quarrying, construction, and foundation drilling applications.

Sinodrills - Your Trusted Back Reamer Manufacturer from China

Sinodrills is your trusted back reamer manufacturer from China, delivering DTH drill bits designed for stable, precise, and efficient drilling. Our back reamers ensure smooth boreholes, prevent wall collapse, and improve overall drilling performance. With durable construction and reliable design, Sinodrills provides solutions for mining, quarrying, construction, and foundation projects worldwide, backed by expertise and quality assurance.

Back Reamer Benefits

Enhanced Hole Stability – Back reamer bits stabilize boreholes during pull-back, reducing the risk of wall collapse. This ensures safer and more reliable drilling operations in unstable or fractured formations.

Improved Hole Cleanliness – These bits effectively remove cuttings while enlarging the hole, resulting in cleaner boreholes. Cleaner holes reduce equipment wear and minimize the likelihood of stuck tools.

Precise Hole Enlargement – Back reamers enlarge boreholes to the desired diameter, providing uniform, smooth holes. This precision supports proper casing installation and consistent blasting or construction results.

Reduced Stuck Tool Risk – By reaming and clearing debris simultaneously, these bits lower the chance of drill rods or hammers becoming stuck, saving time and preventing costly delays.

Increased Drilling Efficiency – The dual function of stabilizing and reaming allows faster drilling cycles. This improves productivity, decreases downtime, and maximizes operational efficiency in mining and construction projects.

Back Reamer Applications

Unstable or Fractured Formations – Back reamers are perfect for drilling through unstable or fractured rock, preventing borehole collapse, maintaining hole integrity, and ensuring smooth operations in challenging geological conditions.

Casing Installation – They facilitate casing installation by enlarging the borehole during pull-back, allowing for easier placement of casings and liners without damaging the surrounding rock or borehole walls.

Water Well Drilling – Back reamer bits improve hole stability and cleanliness during water well drilling, ensuring precise diameters, minimizing sediment accumulation, and enhancing long-term well performance and water flow.

Construction and Foundation Projects – In construction and foundation drilling, back reamers help create stable and accurately sized holes for piles, anchors, or structural supports, improving safety and structural reliability.

Mining and Quarrying Operations – Back reamers are used in mining and quarrying to maintain borehole quality, prevent tool sticking, and enable efficient extraction by ensuring consistent hole geometry and smooth drilling progress.

Various Back Reamer

HDD reamer bits for directional drilling

We offer HDD reamer bits specifically designed for directional drilling, providing precise borehole enlargement and smooth wall finishes. These reamers enhance drilling accuracy, reduce torque and vibration, and ensure efficient pull-back operations. Ideal for utility installation, pipeline projects, and challenging subsurface conditions, our HDD reamer bits deliver reliable performance, extended tool life, and consistent directional control.

horizontal directional drilling Back reamers

We offer horizontal directional drilling (HDD) back reamers designed to enlarge and stabilize drilled paths while maintaining precise alignment. Ideal for utility installation, pipelines, and conduit projects, these reamers ensure smooth boreholes, reduce friction, and prevent collapse. Durable and efficient, they improve pull-back performance, minimize downtime, and enhance overall drilling productivity in challenging underground conditions.

Customize Your Desired Back Reamer

Bit Face Design

We customize the bit face design to match rock formations and drilling conditions. By adjusting the shape, button placement, and reaming angle, we optimize penetration rates, improve cuttings removal, and reduce wear. This ensures stable, smooth boreholes, fewer tool changes, and enhanced overall drilling efficiency for your projects.

Shank Type Selection

We select and customize shank types that ensure perfect compatibility with your hammer or drill rig. Tailoring shank dimensions, locking mechanisms, and material strength improves energy transfer, reduces stress concentration, and prevents misalignment, ultimately extending the tool’s lifespan and maintaining consistent drilling performance.

Material and Hardness Options

We offer customization of materials and hardness levels for reamer bodies and buttons. By choosing high-quality steel, carbide grades, or surface treatments, we enhance wear resistance, impact toughness, and thermal stability, providing a longer-lasting bit that performs reliably in abrasive or hard-rock conditions.

Diameter and Gauge Adjustments

We adjust reamer diameters and gauge sizes to match project specifications. Proper sizing ensures precise hole enlargement, reduces friction during pull-back, prevents borehole collapse, and improves drilling accuracy. Custom gauge design also supports stable operation and consistent results across various formations.

what are back reamers?

Back reamers are specialized DTH drill bits designed to enlarge and stabilize boreholes during the pull-back phase of drilling.

They help maintain precise hole diameter, improve borehole cleanliness, and prevent wall collapse or stuck tools. Commonly used in mining, construction, water well, and horizontal directional drilling projects, back reamers enhance overall drilling efficiency and reliability.

back reamer features

Back reamers are engineered to provide stability, efficiency, and precision in drilling operations. Their design enhances hole quality, prevents collapse, and supports smooth pull-back. By combining durability, optimized cutting geometry, and robust construction, back reamers deliver superior performance for mining, construction, water well, and horizontal directional drilling projects.

Enhanced Hole Stability – Back reamers maintain borehole integrity during pull-back, reducing the risk of collapse or deformation. Their design distributes cutting forces evenly, ensuring straight, smooth holes and consistent diameter. This feature is crucial for unstable or fractured formations, improving safety and minimizing operational delays.

Optimized Cutting Geometry – We design back reamers with carefully arranged buttons and cutting angles to maximize penetration and reaming efficiency. The geometry improves cuttings removal, reduces friction, and enables faster drilling. Optimized cutting surfaces also extend bit life and maintain consistent hole quality in various rock types.

Durable Construction – Back reamers are built with high-strength steel and wear-resistant carbide buttons to withstand high impact and abrasive conditions. Durable construction ensures long service life, minimizes maintenance, and allows for continuous operation in demanding mining, construction, and HDD projects without compromising performance.

Smooth Pull-Back Performance – Back reamers facilitate easy withdrawal of the drill string while enlarging the hole. This reduces pull-back friction, prevents stuck tools, and ensures consistent hole diameter. Smooth pull-back improves overall drilling efficiency and reliability, making operations faster, safer, and more cost-effective.

Versatile Applications – Designed for multiple drilling scenarios, back reamers perform well in mining, construction, water wells, and horizontal directional drilling. Their features adapt to different formations and drilling depths, providing reliable, high-quality results and reducing downtime across diverse project requirements.

Send Your Inquiry Now

All-in-one Back Reamer Solutions for Your Project

All-in-one back reamer solutions provide reliable, efficient, and customized drilling performance for mining, construction, HDD, and foundation projects. Our back reamers stabilize and enlarge boreholes, ensure smooth pull-back, and reduce risks of collapse or tool sticking. With durable materials, optimized design, and versatile applications, we deliver superior hole quality, enhanced productivity, and consistent results for every drilling challenge.