Drilling into unstable ground or highly fractured rock formations presents a major challenge in construction and foundation engineering. Standard drilling methods often fail due to borehole collapse or contamination. Enter the double casing drill bit—a specialized, heavy-duty tool designed precisely to combat these complex geological issues, ensuring stability from the start.

This innovative bit functions by simultaneously drilling and installing a temporary or permanent casing, effectively stabilizing the borehole wall as it advances. Understanding this technology is key for engineers looking to achieve deep, reliable piles or anchor points where ground conditions are unpredictable.

What is a Double Casing Drill Bit?

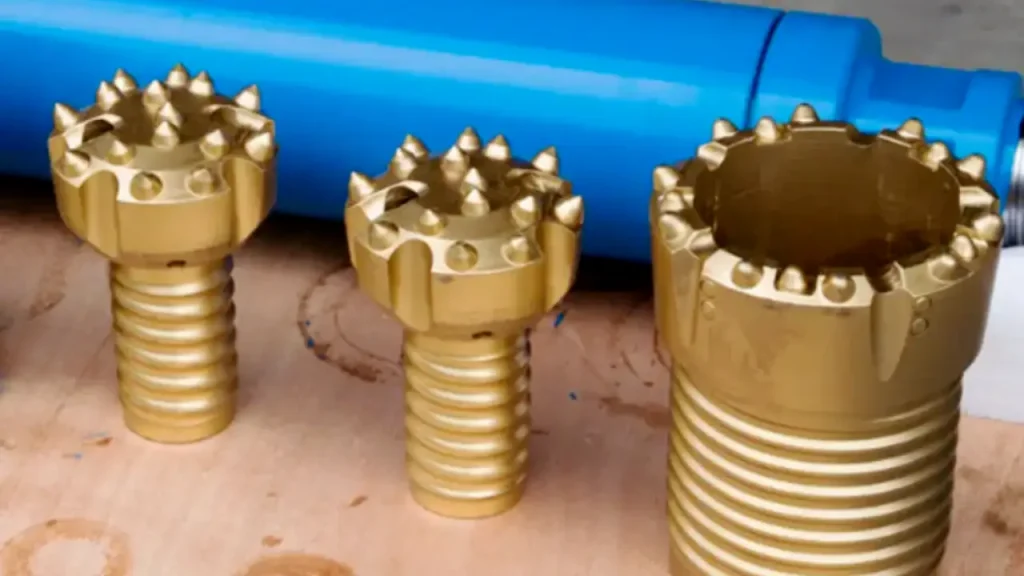

A Double Casing Rock Drill Bit is a specialized drilling tool designed to simultaneously drill a borehole and advance an outer casing into unstable ground or fractured rock formations in a single pass.

It typically incorporates an inner pilot bit which does the initial rock penetration, and an outer reamer bit or ring bit that is permanently or semi-permanently attached to the casing, widening the hole to the required diameter and immediately stabilizing the borehole walls to prevent collapse, gravel intrusion, or caving before the next stage of drilling or final foundation element installation.

Double Casing Drill Bit Benefits

Double casing drill bits offer significant advantages, especially when tackling challenging ground conditions. Their integrated design and simultaneous drilling-casing action streamline operations, enhance safety, and ensure robust foundation work. These benefits make them an indispensable tool in modern deep drilling and piling projects.

Here are the key benefits:

- Enhanced Borehole Stability: This system prevents borehole collapse in loose or unstable soils and fractured rock by instantly advancing the casing as drilling progresses. This continuous support maintains the integrity of the bore, crucial for deep foundations and preventing material loss.

- Improved Drilling Efficiency: By combining drilling and casing installation into one continuous process, these bits significantly reduce overall project time. This integrated approach eliminates the need for separate operations, leading to faster completion rates and lower operational costs per meter drilled.

- Reduced Environmental Impact: Minimizing the risk of borehole collapse also means less disturbance to surrounding ground and reduced potential for contamination. This creates a cleaner, safer worksite, and helps protect nearby structures and natural environments from drilling-related impacts.

- Versatility in Ground Conditions: Double casing bits excel in a wide range of challenging geological environments, including those with running sands, gravel, soft clays, and highly fractured rock. Their robust design allows successful penetration where other drilling methods would fail or be highly inefficient.

- Cost-Effectiveness in Complex Projects: While the initial investment might seem higher, the efficiency gains, reduced risks of re-drilling, and improved project timelines often lead to significant cost savings. This makes them a more economical choice for complex, high-stakes foundation and piling work.

Double Casing Drill Bit Uses

The Double Casing Drill Bit is primarily employed in geotechnical and foundation drilling where hole stability cannot be guaranteed by standard methods. Its main role is to secure the borehole path through challenging subsurface materials from the moment drilling begins, ensuring a high-quality, reliable final structure.

Here are the key applications for this technology:

- Deep Bored Piling and Anchors: This system is extensively used for installing deep foundation piles or tieback anchors in ground susceptible to caving, like loose sands or gravel beds. The immediate casing ensures the concrete or anchor grout is placed into a stable, clean opening.

- Water Well and Geothermal Drilling: In water well construction, the bit ensures the hole remains open while drilling through unconsolidated layers, preventing contamination of the aquifer and protecting the final casing string from being crushed or lost mid-operation.

- Drilling in Unstable Overburden: It is the method of choice when penetrating thick layers of overburden (soft, loose, or mixed materials) atop bedrock. The outer casing acts as a robust shield, allowing drilling to proceed reliably through these tricky, non-cohesive zones.

- Environmental and Coring Projects: For projects requiring pristine core samples or monitoring wells, the integrated casing protects the sample from being contaminated or damaged by unstable surrounding formations during the drilling and retrieval process.

How to Choose Double Casing Drill Bits?

Choosing the correct double casing drill bit is vital for project success, ensuring performance matches the ground you are drilling through. Selection is based on analyzing the subsurface geology, the required casing specifications, and the specific drilling method you plan to employ to optimize both speed and tool life.

Here are the key factors to consider when making your selection:

- Geological Formation Characteristics: Determine the rock/soil type, hardness, and abrasiveness. Harder or highly abrasive rock necessitates bits with robust tungsten carbide or PDC cutters, while softer soils might benefit from a design focused on aggressive cutting and efficient spoil removal.

- Casing and Hole Diameter Requirements: The bit assembly must be sized precisely to drill a hole that accommodates the outer casing’s outside diameter (OD) plus sufficient clearance. Verify the pilot bit size and the reamer OD match your casing specifications for a snug, stable fit.

- Drilling Method and Casing Retention: Consider if you are using a Down-The-Hole (DTH) hammer or a top-hammer rig, as this influences the bit’s connection type and required rotational force. Also decide if you need a permanent casing left in the hole or a retrievable one for reuse.

- Cutter Material and Design: The inner pilot bit cutters (TCI or PDC) should match the expected formation hardness. A well-chosen cutter configuration ensures high penetration rates (ROP) without causing excessive wear, thereby maximizing the footage drilled before needing to pull the assembly.

Conclusion

The double casing drill bit is far more than just another drilling accessory; it’s a critical solution for maintaining borehole integrity in the toughest ground conditions. By integrating drilling and casing functions, it drastically reduces the risk of collapse, delays, and costly rework, making complex piling projects feasible and safer.

Adopting this technology means investing in wellbore stability and project efficiency. Whether dealing with running sands, weak clays, or high water tables, the ability to secure the borehole instantly provides a foundation for successful, deep drilling operations that conventional methods simply cannot achieve.

Ready to equip your next challenging project with reliable, high-performance drilling gear? Sinodrills offers a comprehensive range of superior piling and drilling tools, including advanced double casing systems, built for durability and precision. Contact us today to source the best wholesale piling drilling tools for your needs!