Rock bolts are essential components in construction and mining, providing stability and safety to tunnels, slopes, and underground structures. They work by anchoring loose rock or soil, preventing collapse and ensuring long-term structural integrity. Understanding their function helps engineers select the right solution for each project’s needs.

Different types of rock bolts serve varied applications, from mechanical expansion bolts to resin-grouted bolts. Each type offers unique benefits depending on the environment and load requirements. Proper installation and maintenance are crucial to maximize performance and ensure safety in demanding construction or mining conditions.

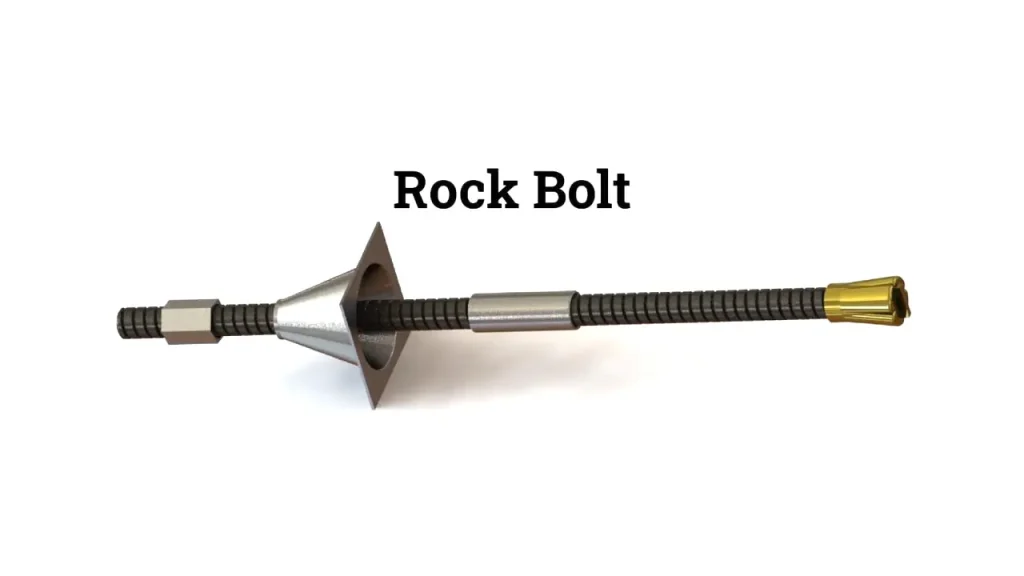

What is a Rock Bolt?

A rock bolt is a structural element used to stabilize rock, soil, or underground formations. Installed in tunnels, slopes, or mines, it anchors loose material to prevent collapse and maintain structural integrity. Rock bolts come in various types, including mechanical, resin-grouted, and fully grouted, each designed to meet specific load, environmental, and safety requirements.

Types of Rock Bolts

Rock bolts come in several varieties to suit different ground conditions, load demands, and installation methods. Each type has a unique method of anchorage and advantage, allowing engineers to choose the best solution for tunnels, mines, slopes, and underground structures.

Mechanical / Mechanically Anchored Rock Bolts

This type uses expansion shells or wedges that mechanically lock the bolt against the rock when installed. Upon inserting the bolt into a drilled hole, the expansion mechanism is activated (often by torque), creating an immediate secure hold — ideal for hard, competent rock where instant support is needed.

Because there is no need for grout or resin, mechanical bolts enable quick installation, making them suitable for temporary support or projects where speed matters. However, their long-term performance depends on the stability and hardness of the surrounding rock.

Grouted (Fully Bonded) Rock Bolts

Grouted bolts — using cement grout or resin — bond the bolt along its entire length to the surrounding rock mass. This “fully bonded” anchorage distributes load evenly and provides stable, long-term support, especially in fractured, weak, or weathered rock conditions.

Installation involves placing the bolt in a drilled hole, injecting the grout or resin, and waiting for it to cure. Although the process takes longer and requires more precision than mechanical anchoring, the resulting bond offers superior load-bearing capacity, stability, and resistance to rock movement or stress over time.

Friction‑Anchored (Friction / Split‑Set / Swellex) Rock Bolts

Friction‑anchored bolts — such as split‑set or hydraulically expanding designs (e.g. Swellex) — rely on radial pressure or friction between the bolt and the borehole wall to hold them in place. This makes them effective where the rock is weak or the ground may shift, since they adapt to irregular borehole surfaces.

These bolts can be installed quickly and provide immediate support without grout or resin, which is especially useful in mining or tunneling where speed and adaptability matter. Their passive support mechanism works well under dynamic conditions, though their load capacity may be lower than grouted or mechanical bolts.

Self‑Drilling Anchor (Hollow / Hollow‑Core) Rock Bolts

Recommended Self Drilling Anchor Systems

Self‑drilling bolts combine drilling, anchoring, and grouting into a single integrated operation. A hollow threaded steel bar (with a sacrificial drill bit on the front) drills into the rock and simultaneously allows grout injection — eliminating the need for a separate borehole and speeding up installation.

This type is especially beneficial in unstable, collapsing, or water‑bearing ground, where conventional bolt installation might be difficult or unsafe. The combined method ensures full-length anchorage, strong bond with surrounding rock, and efficient, fast installation — ideal for tunneling, slope stabilization, and mining work under challenging conditions.

| Rock Bolt Type | Support Mechanism / Anchorage Method | Best for Rock Condition | Key Features / Typical Applications |

|---|---|---|---|

| Mechanical / Mechanically Anchored | Expansion shells or wedges create mechanical lock | Hard, competent rock | Immediate support; quick installation; suitable for temporary or fast‑track works |

| Grouted (Fully Bonded) | Cement or resin grout bonds bolt along entire length | Fractured, weak, weathered rock | Long-term stability; high load capacity; ideal for permanent reinforcement |

| Friction‑Anchored / Split‑Set / Swellex | Radial pressure / friction against borehole wall | Weak to medium rock, shifting ground | Easy, quick installation; immediate ground support; useful in mining/tunneling |

| Self‑Drilling (Hollow‑Core) | Hollow bar drills and injects grout simultaneously | Unstable, collapsing, water‑bearing or fractured rock | Fast, integrated drilling + grouting; full-length anchorage; great for challenging ground. |

Common Rock Bolt Installation Methods

Installing rock bolts correctly is crucial for ensuring stability, safety, and long-term performance in tunnels, slopes, and underground structures. Various installation methods exist depending on rock type, bolt design, and project requirements. Choosing the right method ensures maximum load distribution, proper anchorage, and durability under challenging conditions.

- Drilled and Grouted Installation: This method involves drilling a hole, inserting the bolt, and filling it with cement or resin grout. The grout bonds the bolt to the surrounding rock, creating full-length anchorage. It is ideal for weak, fractured, or water-bearing rock where long-term stability is required.

- Mechanical or Expansion Bolt Installation: Mechanical bolts use expansion shells or wedges that lock the bolt against the rock once inserted. This method provides immediate support and is suitable for competent, stable rock where rapid installation is necessary. It is often used for temporary or quick-support applications.

- Friction / Split-Set Installation: Friction-anchored bolts rely on radial pressure against the borehole wall to stay in place. This technique is fast and effective in medium-strength rock or ground prone to small movements. It requires no grout, making it ideal for mining and tunneling projects.

- Self-Drilling Anchor Installation: Self-drilling bolts combine drilling, grouting, and anchoring in a single operation. The hollow bolt drills into the rock while injecting grout, ensuring full-length support. This method is highly efficient, suitable for unstable, collapsing, or water-bearing ground, and reduces installation time while maintaining strength.

Applications of Rock Bolt

Rock bolts are widely used in construction, mining, and civil engineering projects to ensure stability, safety, and structural integrity. They prevent rock or soil collapse, support excavations, and enhance load-bearing capacity in underground and surface structures. Choosing the right bolt type and installation method is critical for optimal performance.

- Tunnel and Underground Excavations: Rock bolts stabilize tunnel walls and ceilings, preventing collapses during and after excavation. They distribute loads evenly across weak rock zones, ensuring worker safety and structural integrity. Properly installed bolts reduce the risk of deformation or failure in long-term underground projects.

- Slope and Rock Face Stabilization: Bolts secure unstable slopes, cliffs, and rock faces, minimizing landslides and rockfalls. They anchor loose material to more stable strata, providing reinforcement in high-risk areas. This application is essential for highways, dams, and open-pit mining operations.

- Mining and Quarrying Operations: In mining, rock bolts maintain the stability of shafts, drifts, and stopes. They prevent roof collapses and ensure safe working conditions, particularly in deep or fractured rock. Efficient bolt placement reduces downtime and enhances operational productivity.

- Civil and Infrastructure Projects: Rock bolts reinforce foundations, retaining walls, and underground facilities. They provide additional support for bridges, tunnels, and large-scale construction projects, ensuring long-term durability and safety under dynamic loads and environmental pressures.

Conclusion

In summary, rock bolts play a vital role in maintaining the stability and safety of underground and structural projects. By selecting the appropriate type and installation method, engineers can prevent accidents and enhance the durability of their work. Sinodrills offers reliable wholesale rock bolt systems to meet diverse project demands.

Our rock bolt solutions combine strength, corrosion resistance, and easy installation, making them ideal for long-term use in construction and mining environments. With Sinodrills, you can access high-quality wholesale rock bolt systems tailored to your project requirements, ensuring efficiency, safety, and cost-effectiveness.

Choosing Sinodrills for your rock bolt needs guarantees expert support, customizable solutions, and products engineered for durability. Partnering with us ensures your projects benefit from reliable anchoring systems, reducing maintenance costs and enhancing safety across every application. Explore our wholesale rock bolt systems today.