Soil nailing is a modern geotechnical technique used to stabilize slopes, excavations, and retaining walls. By reinforcing soil with steel bars or nails, it increases strength and prevents collapse. This method is cost-effective, adaptable, and suitable for both temporary and permanent stabilization projects, enhancing safety in construction sites.

The process involves drilling holes into the soil, inserting steel bars, and grouting them in place. Combined with a facing system like shotcrete, soil nailing forms a solid, reinforced structure. Understanding its principles, applications, and installation methods helps engineers design safer, more reliable projects while minimizing excavation risks.

What is Soil Nailing?

Soil nailing is a ground reinforcement technique used to stabilize slopes, retaining walls, and excavations.

It involves inserting steel bars or nails into pre-drilled holes and securing them with grout. This method strengthens the soil, prevents collapse, and provides long-term stability for construction and civil engineering projects.

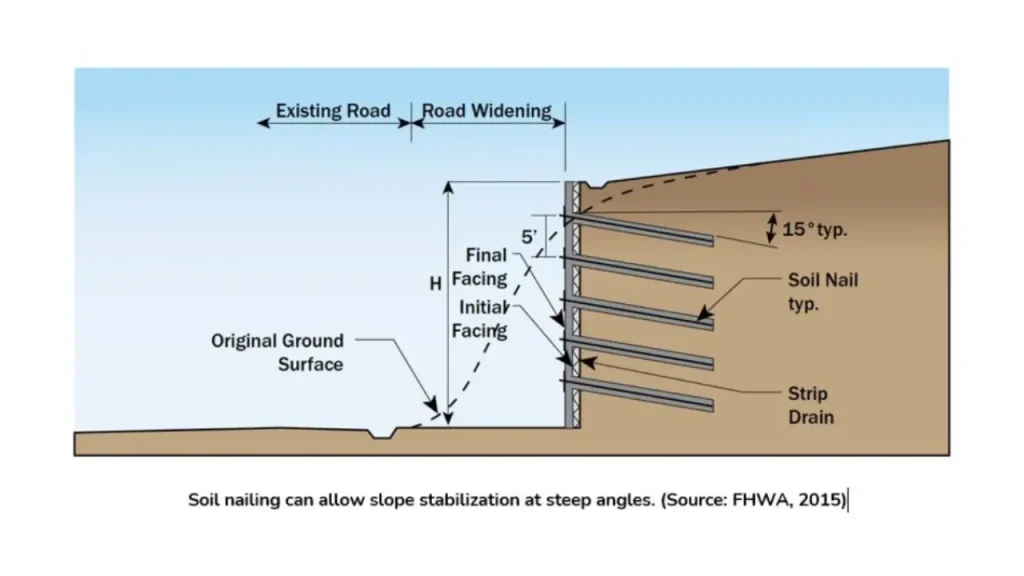

Soil Nailing for Slope Stabilization

Soil nailing is an effective in-situ reinforcement technique we utilize for slope stabilization. This method involves installing closely spaced steel bars, known as “nails,” into the existing ground to create a composite gravity retaining structure. It’s a versatile solution that we provide for both temporary and permanent cut slopes.

- Drilling and Installation: We drill boreholes at a slight downward inclination, inserting the steel nails and typically filling the annular space with grout.

- We offer a precise drilling process to prepare the ground for the nails, ensuring the proper depth and angle for optimal soil interaction. The steel bars are then placed into these holes. This creates the initial resistance needed to stabilize the unstable soil mass efficiently, providing immediate support.

- Grouting: We inject cementitious grout into the borehole to bond the nail to the surrounding soil mass effectively.

- We supply a robust grouting mixture that ensures an excellent bond along the entire length of the nail and the surrounding earth. This bond mobilizes tensile resistance within the nail, which is crucial for countering the destabilizing forces within the slope.

- Application of a Facing: We apply a temporary or permanent facing, such as reinforced shotcrete, to the slope surface after the nails are installed.

We manufacture and install durable facings that distribute the nail head loads across the slope face and prevent surficial erosion and shallow instability. The facing, often a layer of reinforced shotcrete, provides a finished appearance and long-term protection against weathering elements for sustained stability.

Soil Nailing in Ground Improvement Techniques

Soil nailing is a key ground improvement technique used to enhance soil stability and support excavations, slopes, and retaining structures. By reinforcing the soil with steel bars and grout, it increases shear strength, reduces deformation, and prevents erosion or collapse, making construction safer and more efficient in challenging ground conditions.

- Slope Stabilization: Soil nailing strengthens natural or man-made slopes. We insert nails to create a reinforced soil mass that resists movement, prevents landslides, and enhances safety. This technique is effective for highways, embankments, and hillside developments, providing long-term stability and reducing maintenance needs.

- Excavation Support: Temporary or permanent excavation faces benefit from soil nailing. We design nail length, spacing, and inclination to support soil during construction, preventing wall collapse and minimizing disruption. This approach ensures safe working conditions while allowing efficient progress in deep or constrained excavation projects.

- Retaining Wall Reinforcement: Soil nailing complements retaining walls by increasing lateral stability. We integrate nails with concrete or shotcrete facing to distribute loads evenly. This method improves wall performance, extends lifespan, and reduces risk of structural failure, making it suitable for urban and industrial construction projects.

- Erosion Control: Soil nailing reduces surface erosion on slopes and embankments. We combine nails with drainage and surface protection to stabilize soil layers. This prevents soil loss, maintains landscape integrity, and protects infrastructure from water or wind-induced damage, supporting sustainable and resilient construction practices.

- Load-Bearing Capacity Enhancement: Soil nailing improves the load-bearing capacity of weak soils. We reinforce soil to support structures, foundations, and heavy equipment. This technique increases safety margins, reduces settlement risks, and ensures construction projects can withstand operational and environmental stresses over the long term.

How Does Soil Nailing Work?

Soil nailing reinforces slopes and excavations by inserting steel self drilling drilling bars into pre-drilled holes and securing them with grout. This method stabilizes soil, prevents collapse, and enhances load-bearing capacity. The combination of nails and facing material creates a reinforced soil mass that behaves like a coherent, stable structure under stress.

- Drilling Holes: Holes are drilled at a specified angle and spacing into the slope or excavation surface. Proper drilling ensures that the nails reach competent soil layers, providing effective anchorage. Accurate placement is crucial for load distribution and long-term stability of the reinforced soil mass.

- Inserting Steel Nails: Steel bars or nails are inserted into the drilled holes. The nails act as internal reinforcement, transferring loads from unstable soil to stronger surrounding material. This creates a continuous network of support that enhances overall slope or wall stability.

- Grouting or Anchoring: Grout or resin is injected into the hole to bond the nail with the surrounding soil. This secures the nail, prevents slippage, and distributes forces evenly. Proper grouting improves durability, ensuring the reinforced soil can withstand environmental and structural pressures over time.

- Applying Facing Material: Shotcrete, mesh, or other facing systems are applied to the surface to protect soil, prevent erosion, and improve load transfer between nails. The facing also provides immediate surface stability, helping maintain the integrity of slopes and excavations during construction and long-term use.

Applications of Soil Nailing

Soil nailing is widely used in civil engineering and construction projects to stabilize soil, prevent landslides, and reinforce excavations. By integrating steel reinforcement into the soil, it enhances strength and load-bearing capacity, making sites safer and more durable. Understanding the applications helps engineers select the right approach for each project.

Slope Stabilization

Soil nailing is commonly applied to stabilize natural and man-made slopes prone to erosion or landslides. By installing steel nails and facing materials, the soil mass is reinforced, reducing the risk of failure. This method is effective in both steep embankments and highway cuttings.

It distributes loads evenly across unstable soil layers, preventing movement and collapse. Soil nailing can be used in temporary or permanent projects, providing long-term slope stability while minimizing excavation and environmental impact. Engineers rely on it to maintain safety in challenging terrain.

Retaining Walls

Soil nailing supports retaining walls by reinforcing the soil behind them, allowing walls to resist lateral pressure effectively. This technique is especially useful in tight spaces or urban areas where traditional retaining structures may be impractical.

The reinforced soil works as a continuous mass, reducing wall movement and increasing durability. Combined with shotcrete or other facing systems, soil nailing creates a reliable, cost-effective solution for retaining walls in construction, roadways, and landscaping projects.

Excavation Support

During deep excavations, soil nailing provides temporary or permanent support to prevent wall collapse and soil movement. It enables safer construction of basements, tunnels, and underground facilities.

By reinforcing the surrounding soil, the method distributes loads and stabilizes excavation walls, allowing work to proceed without extensive shoring. This minimizes delays, reduces construction risks, and ensures structural integrity in confined or complex sites.

Infrastructure Projects

Soil nailing is used to reinforce slopes and excavations around highways, bridges, railways, and other civil infrastructure. It enhances stability, protects against soil erosion, and prolongs the lifespan of adjacent structures.

It provides a cost-effective, adaptable solution for complex terrains, accommodating challenging soil conditions and varying load requirements. Engineers often combine soil nailing with drainage systems and facing layers to maximize performance and safety.

Can Soil Nails Be Used in All Types of Soil Conditions?

Soil nailing is highly effective in many soil conditions, but its performance depends on soil type, strength, and cohesiveness. Understanding the limitations ensures safe and efficient application. Different soils may require specific nail designs, lengths, and installation methods to achieve optimal stability and long-term reinforcement.

- Cohesive Soils (Clay, Silt): Soil nailing works well in cohesive soils because the nails bond effectively with the surrounding material. Proper grouting and nail spacing distribute loads evenly, enhancing slope stability and reducing the risk of failure in soft, plastic, or moisture-sensitive soils.

- Granular Soils (Sand, Gravel): While possible, granular soils require careful consideration. Nails must be fully grouted or combined with facing systems to prevent slippage. Friction between soil and nail may be lower, so additional reinforcement and proper design are critical for maintaining stability.

- Mixed or Layered Soils: For soils with alternating layers of cohesive and granular material, soil nailing can still be applied with tailored designs. Nail length, spacing, and grouting techniques must be adjusted to account for varying strength and load distribution across layers.

- Weak or Collapsible Soils: In extremely weak, loose, or water-saturated soils, soil nailing may require specialized techniques like self-drilling anchors, pre-grouting, or combining with other support systems. These adaptations improve anchorage and prevent soil displacement or failure during excavation or slope stabilization.

Conclusion

In summary, soil nailing is an efficient and reliable method for stabilizing slopes, retaining walls, and excavation sites. Its combination of steel reinforcement and grout provides enhanced soil strength, load-bearing capacity, and long-term stability. For large-scale projects, Sinodrills offers wholesale self-drilling anchor systems tailored to diverse construction needs.

Our self-drilling anchor systems simplify soil nailing installation, combining drilling and grouting into one operation. This integrated approach reduces labor time, ensures consistent anchorage, and provides maximum structural support. Partnering with Sinodrills guarantees access to high-quality, durable anchors that meet rigorous project requirements while improving safety and efficiency.

Choosing Sinodrills for your soil nailing projects ensures expert guidance, customizable anchor solutions, and reliable products. Our wholesale systems are engineered for challenging soil conditions, offering long-term durability and performance. Get your self-drilling anchor systems today and enhance the safety, stability, and efficiency of your geotechnical projects.