In the complex industry of geological exploration and resource extraction, selecting the appropriate drilling method is paramount. However, even the most advanced techniques falter without the right tool at the cutting edge: the drill bit. Choosing the optimal drill bit, tailored to the specific geological formation, is a critical factor for efficiency, cost-effectiveness, and project success.

This blog post will delve into the diverse array of drilling bits available and guide you through the process of matching them to various geological formations. Understanding the interplay between rock properties and bit design will empower you to make informed decisions, ensuring maximum penetration rates and prolonged bit life on your next drilling venture.

Different Geological Formations

Understanding different geological formations is fundamental to effective drilling. Each formation presents unique challenges and requires specific drilling strategies and tools. Proper identification of these characteristics ensures optimal penetration, minimizes wear on equipment, and enhances overall project efficiency and safety.

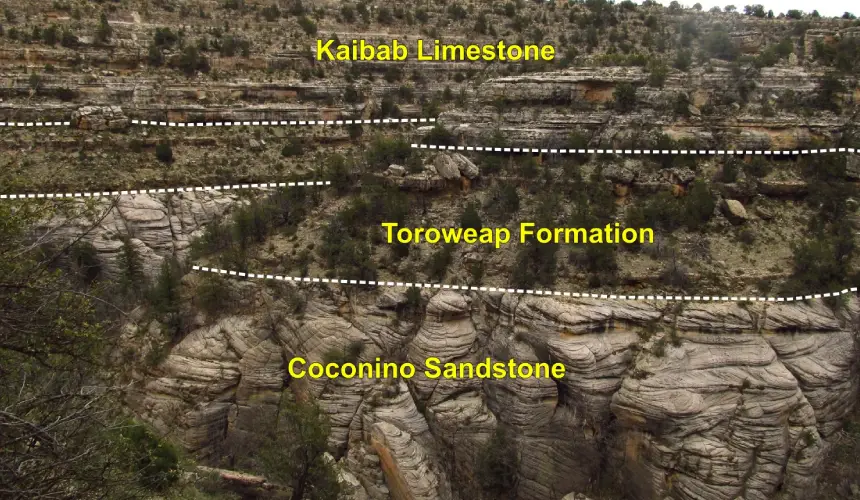

Sedimentary Geological Formation

Sedimentary Geological Formations are formed from the accumulation and compaction of sediments, such as sand, silt, clay, and organic matter, over millions of years. They often exhibit layering (bedding) and can range from soft, unconsolidated sands and clays to harder, more cemented sandstones and limestones.

Drilling in these formations requires careful consideration of stability, fluid loss, and often utilizes roller cone bits or PDC bits designed for softer to medium formations, with a focus on preventing borehole collapse and managing fluid circulation.

Igneous Geological Formation

Igneous Geological Formations are created from the cooling and solidification of molten rock (magma or lava). They are typically very hard and abrasive, like granite, basalt, and gabbro, often exhibiting crystalline structures.

Drilling through igneous formations demands extremely durable drill bits, such as impregnated diamond bits or robust tricone bits with tungsten carbide inserts (TCI) designed for hard rock. High weight on bit and slower rotation speeds are common strategies to effectively penetrate these tough formations, managing significant wear on drilling tools.

Metamorphic Geological Formation

Metamorphic Geological Formations are rocks that have been transformed by intense heat, pressure, or chemical alteration from pre-existing igneous, sedimentary, or other metamorphic rocks. Examples include marble, slate, gneiss, and schist.

Their properties can vary widely depending on the original rock and the degree of metamorphism, often resulting in very hard, dense, and sometimes fractured or foliated structures. Drilling in these formations requires versatile bits, often TCI tricones or PDC bits with aggressive cutters, capable of handling varying hardness and potential fracturing, sometimes necessitating careful fluid management to prevent formation damage.

Unconsolidated Geological Formation

Unconsolidated Geological Formations consist of loose, uncemented particles such as sand, gravel, silt, and clay. These formations lack the solid rock matrix found in consolidated formations, making them prone to caving, heaving, and loss of circulation.

Drilling in unconsolidated formations often employs specialized techniques like casing while drilling, or uses bits designed to minimize disturbance, such as drag bits or specific PDC bits, often with very careful control of drilling fluid density and viscosity to maintain borehole stability.

Karst Geological Formation

Karst Geological Formations are characterized by soluble bedrock, typically limestone, dolomite, or gypsum, that has been extensively dissolved by groundwater, creating a landscape of sinkholes, caves, and underground drainage systems.

Drilling through karst formations presents significant challenges due to the unpredictable presence of large voids, fractured zones, and highly permeable sections. This often leads to severe circulation loss, sudden bit drops, and instability. Specialized drilling techniques, such as air drilling, foam drilling, or utilizing lost circulation materials and casing programs, are often necessary to navigate these complex and highly permeable environments.

Different Drilling Methods in Geology

Understanding different drilling methods in Geology is fundamental for successful subsurface investigations and resource extraction. Each method is tailored to specific geological conditions, desired outcomes, and economic considerations. Choosing the right approach ensures efficient penetration, accurate data collection, and optimal project completion.

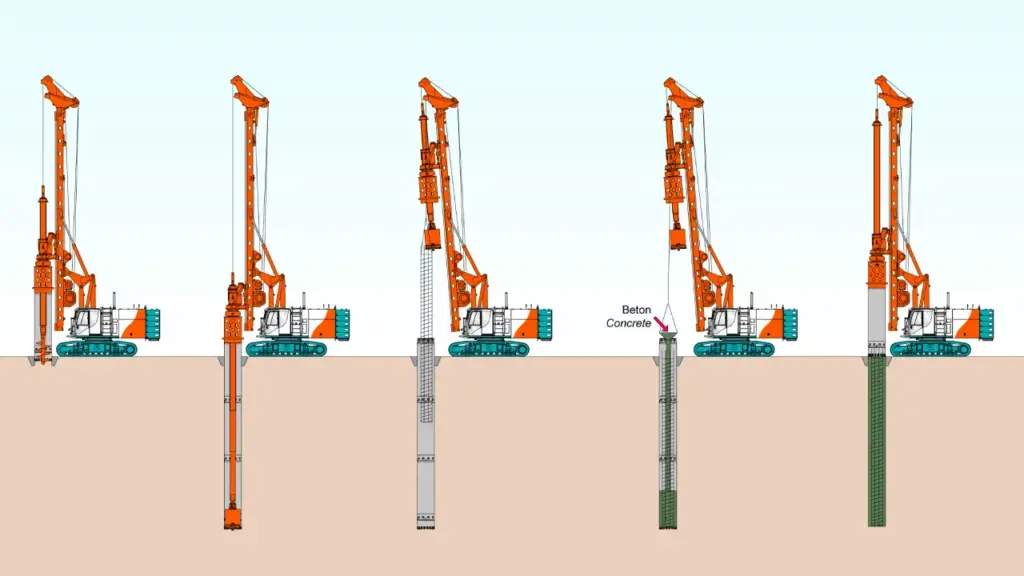

Rotary Drilling Method

Rotary Drilling Method involves rotating a drill bit attached to a drill string, which grinds and cuts through rock formations. Drilling fluid (mud or air) is circulated down through the drill pipe to cool the bit, remove cuttings, and stabilize the borehole. This method is highly versatile and widely used in oil and gas, geotechnical, and mining applications, capable of reaching great depths in various rock types, from soft sediments to hard igneous formations, by selecting appropriate drill bits and fluid systems.

Percussion Drilling Method

Percussion Drilling Method, also known as hammer drilling or churn drilling, involves repeatedly striking the rock surface with a heavy bit, breaking it into smaller pieces. This method is particularly effective in hard, brittle rock formations where rotary drilling might be slow or inefficient. Common tools include down-the-hole (DTH) hammers, which use compressed air to drive a piston that impacts the bit. Percussion drilling is often used for blasting holes, water wells, and in mining, providing high penetration rates in competent rock.

Core Drilling Method

Core Drilling Method is a specialized technique designed to extract cylindrical samples (cores) of rock or soil from the subsurface. A core barrel, equipped with an annular diamond or carbide-tipped bit, rotates and cuts around a central column of material, which is then retrieved. This method is invaluable for geological exploration, geotechnical investigations, and mineral analysis, providing intact samples for detailed study of stratigraphy, rock properties, and ore body characteristics, offering crucial insights for project planning and design.

Directional Drilling Method

Directional Drilling Method involves intentionally steering the drill bit to create a borehole that deviates from a vertical path, reaching targets that are not directly beneath the rig. This method uses specialized tools like steerable motor assemblies, rotary steerable systems, and measurement-while-drilling (MWD) tools to control the direction and inclination of the wellbore. It is extensively used in oil and gas to access multiple reservoirs from a single surface location, avoid obstacles, or increase reservoir exposure in horizontal wells, maximizing resource recovery.

Reverse Circulation (RC) Drilling Method

Reverse Circulation (RC) Drilling Method is a dry drilling technique commonly used in mineral exploration for collecting high-quality, uncontaminated rock chip samples. It employs a dual-wall drill pipe system where compressed air drives a hammer, and cuttings are transported up the inner tube by the reverse flow of air. This method provides rapid sample collection with minimal contamination, making it highly efficient for defining ore bodies and geological mapping, particularly in arid regions where water for conventional drilling is scarce.

How to Choose a Suitable Drilling Method for Different Geological Formations?

Choosing the suitable drilling method for a given geological formation is a critical decision that profoundly impacts the efficiency, cost, and success of any subsurface project. It requires a thorough understanding of the formation’s characteristics, including its hardness, abrasiveness, stability, and the presence of fluids or voids. The right method maximizes penetration rates, minimizes wear on drilling tools, ensures accurate sample collection, and mitigates risks such as borehole collapse or lost circulation. An informed choice prevents costly delays and optimizes resource utilization.

The selection process is a balance between technical feasibility and economic viability. It involves considering not only the immediate challenges presented by the geology but also the overall project objectives, such as the required depth, the type of data or sample needed, and environmental considerations. By carefully evaluating all these factors, engineers and geologists can implement a drilling strategy that is both effective in overcoming geological hurdles and efficient in achieving project goals within budget and schedule.

Geological Formation Properties:

- Hardness and Abrasiveness: For hard, abrasive formations (e.g., granite, quartzite, basalt), percussion drilling (DTH hammer) or rotary drilling with robust bits (e.g., TCI tricones, impregnated diamond bits) are typically more effective. Softer, unconsolidated formations (e.g., sand, clay) might favor rotary drilling with drag bits or PDC bits, often with specialized fluid management.

- Stability and Cohesion: Unconsolidated or fractured formations (e.g., gravel, highly jointed rock, karst) require methods that prevent borehole collapse, such as casing while drilling, careful use of drilling fluids, or air/foam drilling. Cohesive formations allow for more conventional open-hole drilling.

- Presence of Fluids/Voids: Water-bearing zones, highly permeable formations, or karstic voids can lead to lost circulation. Methods like air/foam drilling, reverse circulation, or using lost circulation materials are crucial in these scenarios.

Project Objectives:

- Data/Sample Requirements: If intact core samples are needed for detailed geological analysis (e.g., mineral exploration, geotechnical investigations), core drilling is the method of choice. If only rock chips are sufficient (e.g., reconnaissance drilling, grade control), rotary or RC drilling might be more efficient.

- Depth and Diameter: Very deep wells typically utilize rotary drilling. Larger diameter holes might require specific large-diameter bits and powerful rotary rigs, while small-diameter holes are common in geotechnical or specialized exploration using core drilling or small-diameter percussion rigs.

- Well Trajectory: For reaching targets not directly below the rig or maximizing reservoir exposure, directional drilling (using rotary steerable systems or mud motors) is essential.

Environmental and Logistical Constraints:

- Water Availability: In arid regions, air or RC drilling might be preferred to minimize water consumption compared to conventional mud rotary drilling.

- Waste Management: The type and volume of drilling waste (cuttings and fluid) will influence method selection and require appropriate disposal planning.

- Accessibility: Remote locations or sites with limited space might favor smaller, more portable drilling rigs, potentially influencing the feasible drilling methods.

Economic Considerations:

- Cost per Meter: The overall cost per drilled meter, including rig time, consumables (bits, drill pipe, drilling fluids), and potential non-productive time (NPT) due to formation challenges, plays a significant role. Sometimes, a more expensive initial bit or method can lead to lower overall costs due to higher penetration rates and fewer issues.

- Equipment Availability: The availability of specialized rigs and tools for specific methods (e.g., a large-capacity RC rig or a sophisticated directional drilling system) will influence the practical choices.

Conclusion

The success of any geological drilling project ultimately hinges on the intelligent selection of your drill bit. By carefully considering the nuances of each geological formation and matching them with the appropriate bit type, you can dramatically enhance drilling efficiency, extend equipment lifespan, and significantly reduce operational costs. This strategic approach ensures optimal penetration and performance, even in the most challenging ground conditions.

Mastering the art of drill bit selection is a continuous process of learning and adaptation, but it is one that yields substantial returns in terms of project timelines and profitability. Armed with this knowledge, you are better equipped to tackle diverse geological challenges, from soft sediments to hard, abrasive rock, with confidence and precision.

For all your drilling bit needs, from tricones to PDC, get wholesale drilling tools from us. We provide a comprehensive range of high-quality drill bits designed for every geological formation, ensuring you always have the right tool for the job.