Drill rods are the unsung heroes of countless heavy-duty projects, forming the crucial connection between the drill rig and the cutting bit. Their versatility and durability make them indispensable across numerous industries. Understanding their specific applications is key to appreciating their role in modern construction and resource extraction.

From the deepest mines to the largest construction sites, drill rods are essential for creating the holes needed for blasting, rock reinforcement, and foundation work. This blog will explore the diverse and critical applications of drill rods, highlighting how they enable productivity and safety in some of the world’s most challenging environments.

What are Drill Rods?

Recommended Drill Rods

Drill rods, in the field of rock drilling, are the essential steel tubes that connect the drilling machine to the drill bit. Their primary function is to transmit both the powerful rotational torque and the high-frequency impact energy from the drifter to the bit, enabling it to break rock.

Constructed from high-quality alloy steel and often featuring specialized heat treatments, these rods are engineered to withstand extreme stresses, including tension, compression, and torsion. They are a fundamental component of any drill string, allowing for deep and precise drilling in various applications across the mining, construction, and quarrying industries.

Drill Rod Applications

Drill rods are a fundamental component of modern drilling, serving a wide array of applications across various heavy industries. Their design and durability make them indispensable for a range of tasks, each demanding specific characteristics from the drill string.

Here we explore the key applications where drill rods are used to facilitate progress and ensure safety.

Mining and Quarrying

In mining, drill rods are used for both surface and underground operations to create blast holes for ore extraction. These rods, often in the form of extension rods, enable drilling to great depths in hard rock formations. The rods must be robust to withstand constant percussive force and rotational torque while maintaining hole straightness, which is crucial for efficient blasting and resource recovery.

In quarrying, drill rods are essential for bench drilling. This process involves creating a series of vertical holes in a rock face to a specific depth. The consistent performance of drill rods ensures that these holes are uniform, which is critical for controlled blasting to produce the desired rock fragmentation and maintain safe working conditions in the quarry.

Tunneling and Underground Excavation

For tunneling projects, drill rods are used to create the necessary boreholes for rock excavation and reinforcement. The drill rods facilitate the drilling of blast holes for the initial tunnel excavation. Additionally, they are used to install rock bolts and anchors, which are vital for stabilizing the tunnel’s roof and walls, preventing rock falls and ensuring the safety of workers and the long-term integrity of the structure.

In confined underground spaces, specialized drill rods, such as MF (Male-Female) rods, are often preferred. Their integrated design simplifies handling and speeds up the drilling process, which is a significant advantage in environments where space is limited and time is of the essence. The rigidity of these rods also helps to maintain hole straightness over long drilling runs.

Foundation and Pile Drilling

Drill rods are a key component in civil engineering and construction for foundation work. They are used to drill deep holes to create foundations for large structures like bridges, high-rise buildings, and dams. The rods must be strong enough to penetrate various geological strata, from soil and gravel to competent bedrock, to ensure the foundation’s stability and strength.

In projects requiring micro-piles or anchors, drill rods are used to create small-diameter, deep holes to stabilize slopes or reinforce existing structures. The precision and depth achievable with drill rods are critical for these applications, as the holes must be accurately placed to transfer loads effectively and prevent ground movement.

Bench Drilling and Surface Blasting

Drill rods are fundamental to the process of bench drilling in surface mining and construction. This technique is used to create a series of uniformly spaced holes in a rock face, or “bench,” for controlled blasting. The consistent performance and durability of the drill rods are crucial for achieving uniform hole depth and alignment, which directly impacts the efficiency of the blasting and the fragmentation of the rock.

The reliability of drill rods in this application is paramount. Any failure or deviation can lead to inefficient blasting, creating oversized rock fragments that are difficult to handle, or, in a worst-case scenario, result in an unsafe blasting event. High-quality rods ensure the entire drilling pattern is executed correctly for optimal results.

Geotechnical and Exploration Drilling

In geotechnical and exploration drilling, drill rods are used to obtain core samples from deep underground for geological analysis. The rods connect the drill bit to the surface, allowing for the extraction of intact rock cores. This process is essential for understanding a site’s geological makeup, assessing the viability of a mineral deposit, or determining the best location for a new construction project.

For exploration drilling, drill rods must be able to withstand significant lengths and maintain hole straightness over thousands of feet. The rods must also be precision-engineered to minimize vibration and protect the core sample from damage during the drilling process, ensuring the integrity of the data collected for geologists and engineers.

Horizontal Directional Drilling

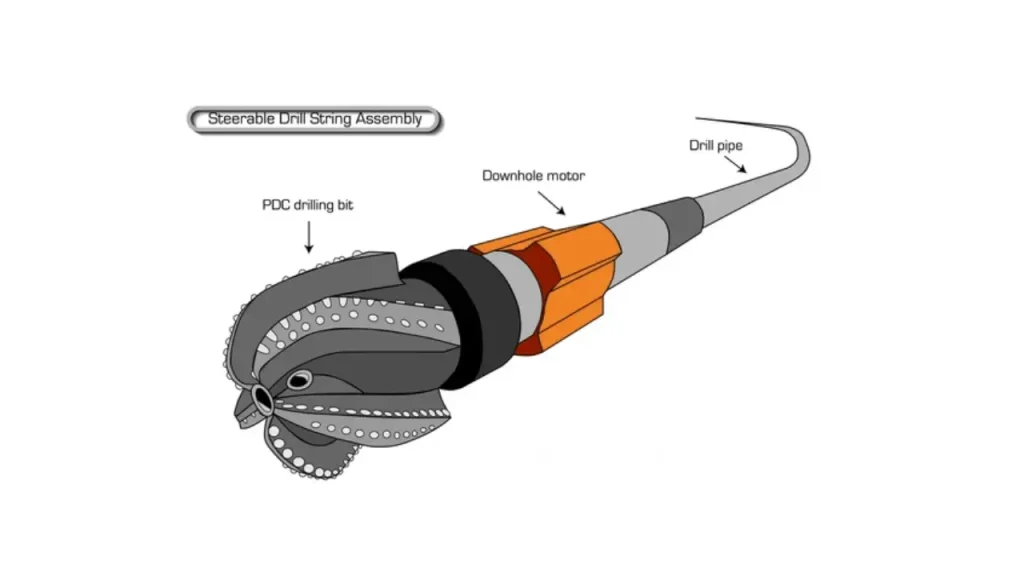

In trenchless construction, drill rods are the conduits for Horizontal Directional Drilling (HDD). They are used to create a pilot bore from a surface entry point to an exit point, often passing beneath rivers, roads, or existing infrastructure. The rods transmit torque from the rig, push and pull the drill string, and act as a channel for drilling fluids.

Specialized drill rods for HDD must possess a unique combination of strength and flexibility to navigate complex curves and withstand the forces of thrust, torque, and friction encountered during the boring process. They also play a crucial role in steering the drill bit along its pre-designed path, enabling the trenchless installation of pipes and cables.

How to Use Drill Rods?

Drill rods are a fundamental component of rotary-percussive drilling systems, used to transmit rotation and percussive energy from the rock drill to the drill bit. Understanding their proper use is key to ensuring efficiency and safety.

Step 1: Preparation and Inspection

Before starting, always inspect each drill rod for any signs of damage, such as cracks, bends, or worn threads. Ensure all connections are clean and free of debris to guarantee a tight, secure fit. Proper preparation minimizes the risk of component failure during drilling.

Once the rods are checked, stage them near the drill rig in the order they will be used. This organization streamlines the process of adding new rods to the drill string. Having a clear plan reduces downtime and increases overall operational efficiency.

Step 2: Assembling the Drill String

Begin by connecting the first drill rod to the rock drill’s shank adapter. Tighten the connection firmly but avoid over-torquing, which can damage the threads. Proper alignment is crucial to ensure smooth energy transfer and prevent premature wear on all components.

As you drill deeper, add subsequent rods one by one. Connect the new rod to the end of the existing string, carefully aligning the threads. Use a rod wrench to tighten the connection securely, ensuring it’s robust enough to withstand high stress.

Step 3: Drilling and Monitoring

During drilling, continuously monitor the performance of the drill string. Pay attention to any unusual vibrations or changes in drilling speed, which could indicate a problem. Maintaining consistent feed pressure is essential to prevent jamming and ensure efficient rock penetration.

Throughout the process, periodically check the drill rods for any signs of wear or heat buildup. If a rod shows excessive wear, replace it promptly to prevent a costly failure. Regular monitoring and maintenance are key to a safe and productive drilling operation.

Conclusion

In conclusion, drill rods are far more than simple pieces of metal; they are the backbone of modern rock drilling, enabling a vast range of critical applications. Their design and material science allow them to withstand immense stresses, making them essential for everything from resource extraction in mines to foundation work for new buildings.

Choosing the right type of drill rod for each specific application is paramount to achieving efficiency and ensuring safety. Whether for long-hole drilling, tunneling, or surface blasting, the proper drill rod ensures optimal energy transfer, hole straightness, and overall project success, underscoring their importance in the field.

For all your drilling needs, we invite you to explore our extensive range of high-quality drill rods at Sinodrills. We offer a comprehensive selection of rods designed for superior performance and durability in any application. Contact us today to learn more about our wholesale options and how we can support your next project.