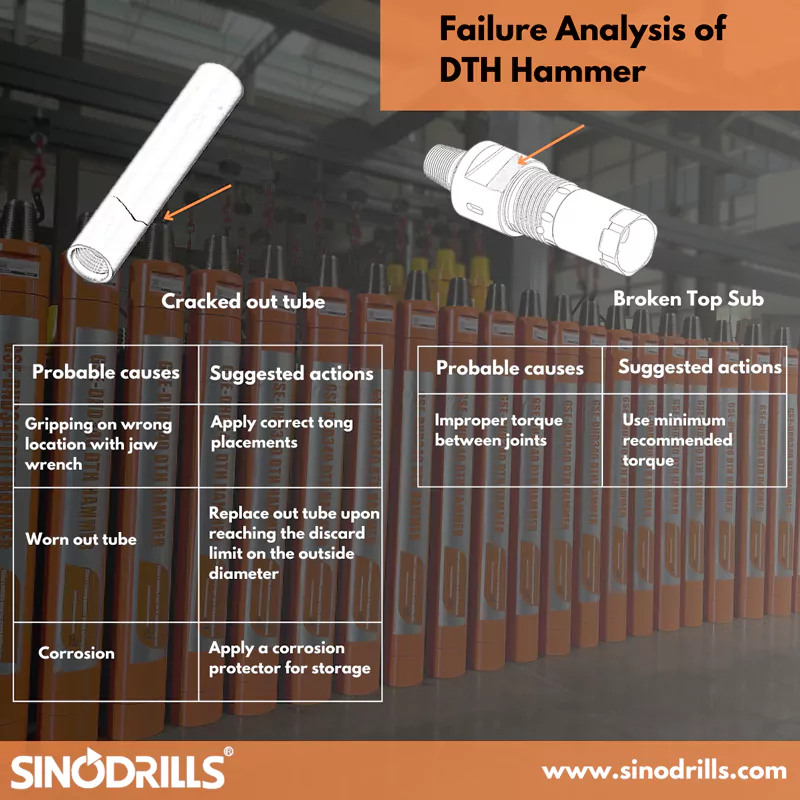

1. Broken drive sub

Probable causes:

– Gap between drive sub shoulder and out tube

– The joint is loose

– Insufficient feed pressure

– Threads lacking lubrication

Suggested actions:

– Implement appropriate tightening torque

– Enhance feed force in soft and unconsolidated rock conditions

– Ensure sufficient feed pressure

– Replace drive sub

– Use appropriate type and amount of grease to the drive sub threads

2. Cracked drive sub

Probable causes:

– Mishandling with sledge hammer

Suggested actions:

– Utilize tongs or chains to detach the drive sub from out tube

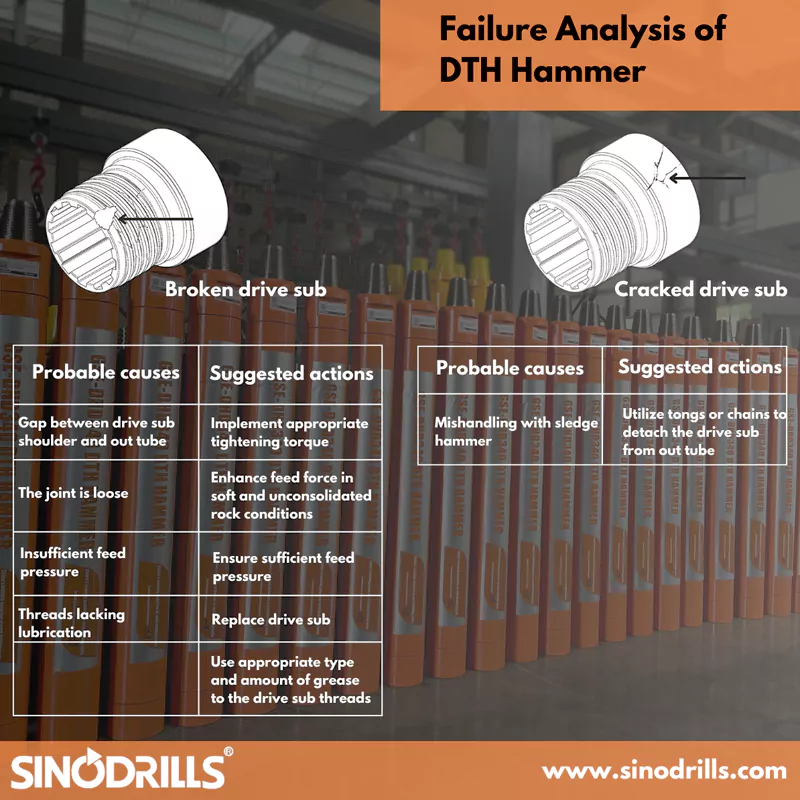

3. Broken piston

Probable causes:

– Galling

– Corrosion at piston undercut

Suggested actions:

– Clean the hammer with foam after drilling

– Check lubrication regularly; use the correct type and quantity of hammer oil

4. Piston cracked

Probable causes:

– Incorrect wrenching location

– Inadequate lubrication

– Stuck in the hole

– Hole deviation

Suggested actions:

– Inspect the lubrication system and ensure oil film is formed in bit flushing holes

– Use wrenching areas to prevent distortion on out tube

– Use water when stuck because friction can cause distort

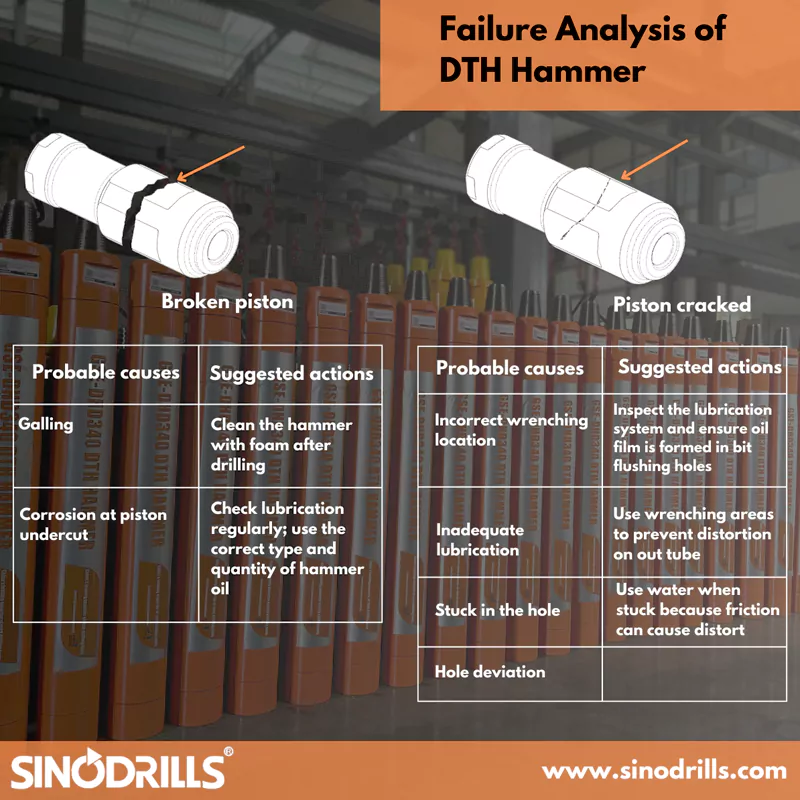

5. Cracked out tube

Probable causes:

– Gripping on wrong location with jaw wrench

– Worn out tube

– Corrosion

Suggested actions:

– Apply correct tong placements

– Replace out tube upon reaching the discard limit on the outside diameter

– Apply a corrosion protector for storage

6. Broken Top Sub

Probable causes:

– Improper torque between joints

Suggested actions:

– Use minimum recommended torque