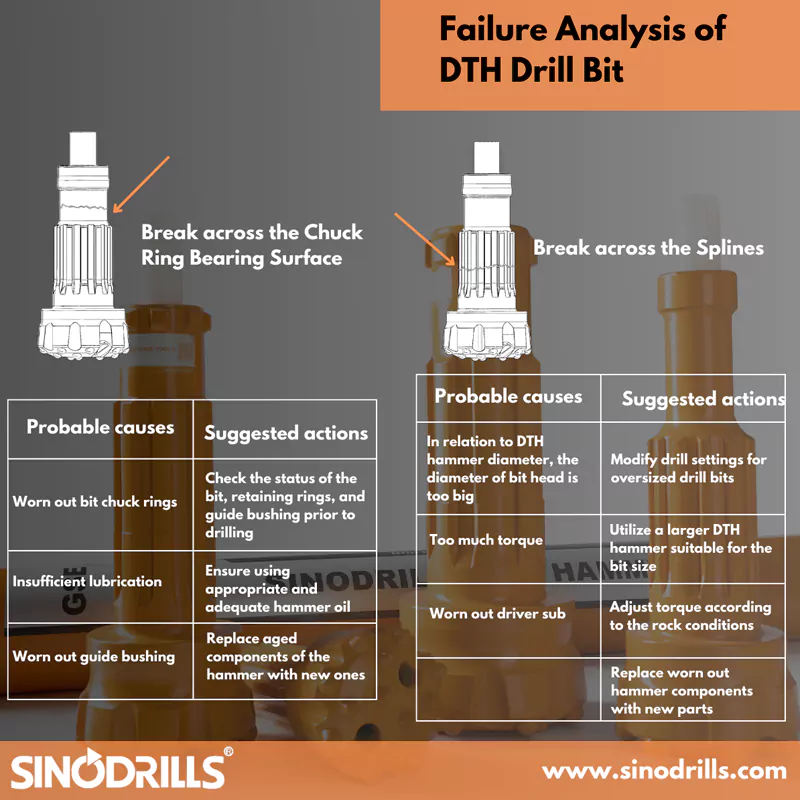

1. Break across the Chuck Ring Bearing Surface

Probable causes:

– Worn out bit chuck rings

– Insufficient lubrication

– Worn out guide bushing

Suggested actions:

– Check the status of the bit, retaining rings, and guide bushing prior to drilling

– Ensure using appropriate and adequate hammer oil

– Replace aged components of the hammer with new ones

2. Break across the Splines

Probable causes:

– In relation to DTH hammer diameter, the diameter of bit head is too big

– Too much torque

– Worn out driver sub

Suggested actions:

– Modify drill settings for oversized drill bits

– Utilize a larger DTH hammer suitable for the bit size

– Adjust torque according to the rock conditions

– Replace worn out hammer components with new parts

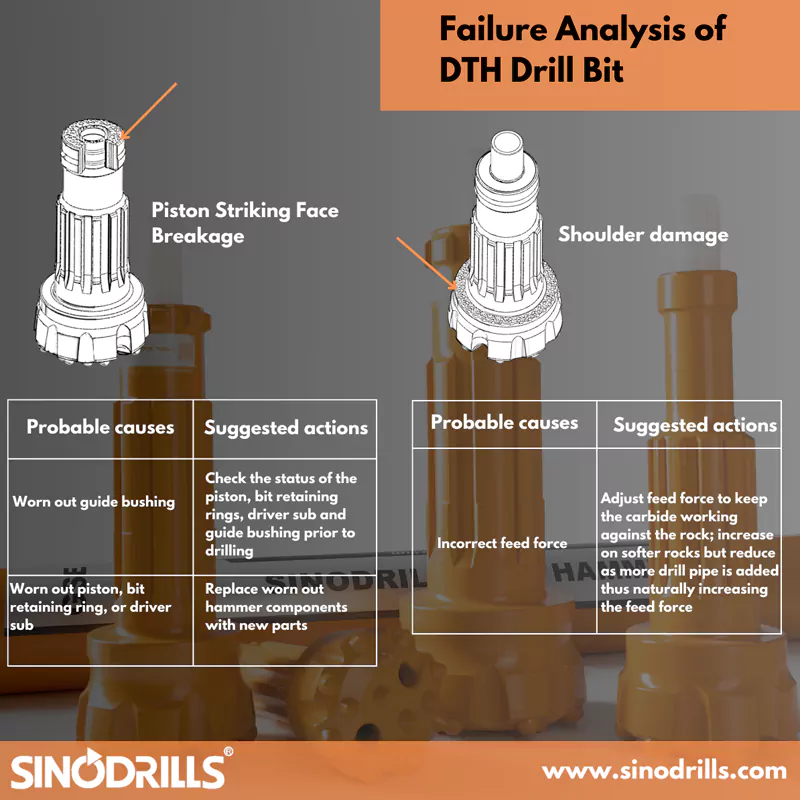

3. Piston Striking Face Breakage

Probable causes:

– Worn out guide bushing

– Worn out piston, bit retaining ring, or driver sub

Suggested actions:

– Check the status of the piston, bit retaining rings, driver sub and

guide bushing prior to drilling

-Replace worn out hammer components with new parts

4. Shoulder damage

Probable causes:

– Incorrect feed force

Suggested actions:

– Adjust feed force to keep the carbide working against the rock; increase on softer rocks but reduce as more drill pipe is added thus naturally increasing the feed force

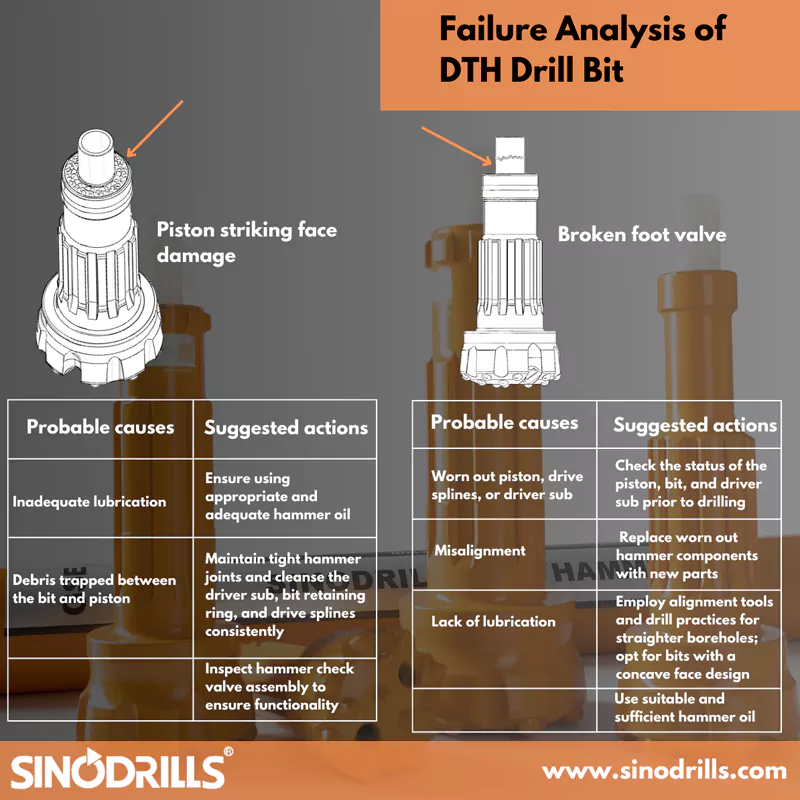

5. Piston striking face damage

Probable causes:

– Inadequate lubrication

– Debris trapped between the bit and piston

Suggested actions:

– Ensure using appropriate and adequate hammer oil

– Maintain tight hammer joints and cleanse the driver sub, bit retaining ring, and drive splines consistently

– Inspect hammer check valve assembly to ensure functionality

6. Broken foot valve

Probable causes:

– Worn out piston, drive splines, or driver sub

– Misalignment

– Lack of lubrication

Suggested actions:

– Check the status of the piston, bit, and driver sub prior to drilling

– Replace worn out hammer components with new parts

– Employ alignment tools and drill practices for straighter boreholes; opt for bits with a concave face design

– Use suitable and sufficient hammer oil