In the demanding world of rock drilling, the strength of a drill rod is paramount. For years, conventional welding methods were the standard, but they often created weak points and led to premature failure. Today, a revolutionary process is transforming the industry: friction welding.

Friction welding is a solid-state joining process that creates a molecular bond between two metals without melting them. This technique is the secret behind producing high-performance, fatigue-resistant drill rods. It’s a method that ensures a seamless, incredibly strong joint, a crucial factor for withstanding the punishing forces of drilling.

What is Friction Welding?

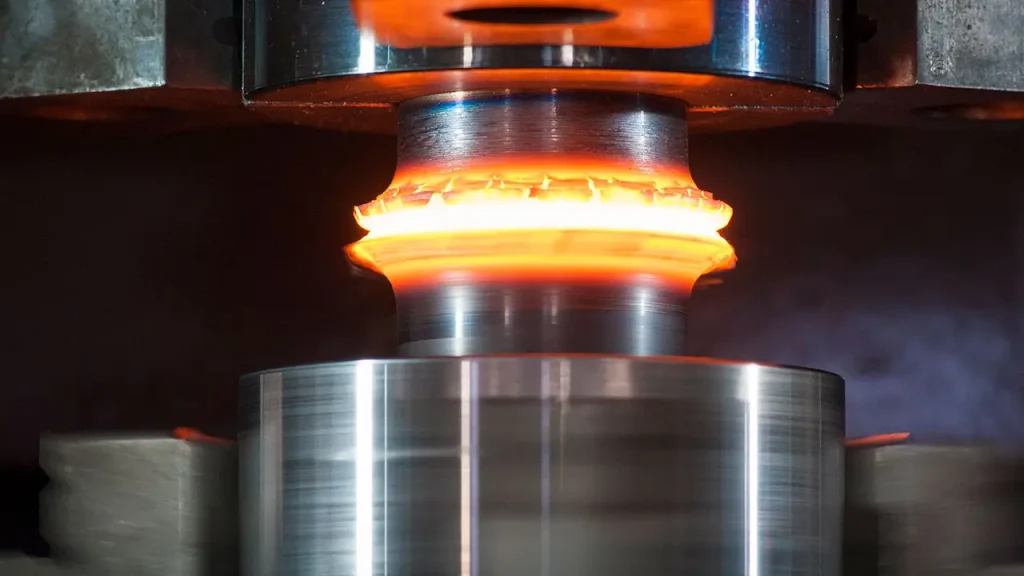

Friction welding is an advanced solid-state joining process that creates a high-strength bond between two materials without melting them. It works by bringing two surfaces together under high pressure while one piece is rapidly rotated against the other.

The friction generated at the interface heats the materials to a plastic state, allowing them to fuse together at a molecular level. This process creates a joint that is stronger and more uniform than those made with conventional fusion welding, as it avoids the formation of brittle zones and other defects associated with melting and solidification. It is an ideal method for joining dissimilar metals and for producing components that require exceptional durability.

Friction Welded Drill Rods

Recommended Friction Welding Drill Rods

Friction-welded drill rods are a cornerstone of modern drilling, designed for maximum durability and performance. This advanced manufacturing technique creates a seamless, high-strength bond between the steel drill tube and the threaded tool joint, eliminating the weak points found in traditional welding methods.

- Superior Joint Strength: The friction welding process forges a molecular bond between the rod and the tool joint without melting the metal. This solid-state weld is stronger and more resistant to fatigue than conventional fusion welds, reducing the risk of joint failure.

- Optimal Fatigue Resistance: By avoiding the heat-affected zones and brittle structures of traditional welding, friction-welded drill rods have exceptional fatigue resistance. This allows them to withstand the constant percussive and rotational forces of drilling, extending their service life.

- Consistent Performance: The uniform and precise nature of friction welding ensures that every drill rod joint is of the same high quality. This consistency guarantees reliable power transmission from the drill rig to the bit, leading to predictable and efficient drilling performance.

- Cost-Effectiveness: The enhanced durability and longer lifespan of friction-welded drill rods mean fewer replacements and less downtime. This translates directly to a lower overall drilling cost per meter, making them a more economical choice in the long run.

How Does Friction Welding Work?

Friction welding works through a four-step process that creates a strong bond between two components without melting them. This solid-state method relies on a combination of mechanical force and generated heat, resulting in a joint that is superior in strength and integrity to those created by traditional fusion welding.

- Rotation: One piece is held stationary while the other is rotated at a high speed. This creates friction when the two surfaces are brought together, generating intense heat at the interface.

- Heating: The friction heats the two surfaces to a plastic state, but not to the melting point. The materials become soft and malleable, ready to be forged together under pressure.

- Forging: The rotation is stopped, and a powerful forging force is applied to press the two pieces together. This pressure fuses the materials at a molecular level, creating a solid and seamless bond.

- Cooling: The newly forged joint is allowed to cool. The rapid cooling ensures the materials retain their original metallurgical properties, resulting in a joint that is as strong or even stronger than the parent metals.

Advantages of Friction Welding

Friction welding offers significant advantages over conventional fusion welding, which makes it a preferred method for critical applications like joining drill rods. These benefits of friction welding stem from the process’s ability to create a high-integrity, solid-state bond.

- Superior Joint Strength: Friction-welded joints are typically stronger and more fatigue-resistant than those made with conventional welding. The process avoids the weak, brittle heat-affected zones and internal defects like porosity and cracking that can occur with melting.

- Preservation of Material Properties: Since the materials are heated only to a plastic state and not melted, their original metallurgical properties are largely preserved. This ensures the finished product, such as a drill rod, maintains its designed hardness and strength.

- High Efficiency and Speed: The friction welding process is exceptionally fast, often completing a bond in a matter of seconds. This high speed, combined with its simple operation, makes it ideal for high-volume production lines.

- Versatility in Joining Dissimilar Metals: Friction welding is capable of creating strong bonds between a wide range of dissimilar metals that would be difficult or impossible to join with traditional welding methods.

- Environmental and Safety Benefits: The process is cleaner and safer than fusion welding. It does not require filler materials, fluxes, or shielding gases, and it produces no harmful fumes or arc flashes, making it an environmentally friendly choice.

Application of Friction Welding

Friction welding’s ability to create high-strength, low-defect joints makes it a vital process in numerous industries where component integrity is paramount. Its primary application in the context of drill rods is to join the threaded end pieces to the main steel body, but its use extends to many other critical components.

- Drill Rod Manufacturing: This is a major application. Friction welding is used to join tool joints (the threaded ends) to the drill pipe or rod body. This creates a joint that is stronger and more fatigue-resistant than those made with conventional welding, which is essential for withstanding the immense rotational and percussive forces in drilling.

- Automotive Industry: Friction welding is extensively used to produce various parts, including engine valves, drive shafts, and axle casings. The process creates strong, lightweight components that can withstand high stress and vibration, improving vehicle performance and fuel efficiency.

- Aerospace Industry: In aerospace, friction welding is used for joining components like jet engine parts, landing gear, and turbine shafts. The process is valued for its ability to join dissimilar high-strength alloys and maintain the integrity of critical components operating under extreme conditions.

- Marine and Oil & Gas: The process is used for joining heavy-duty pipes and shafts in these industries. Friction-welded joints are highly resistant to corrosion and fatigue, making them ideal for subsea equipment, risers, and other components in harsh marine environments.

- Tool Manufacturing: Beyond drill rods, friction welding is used to produce a variety of cutting tools, drills, and bits. It allows for the fusion of different materials—such as high-speed steel and carbon steel—to create tools that have a hard cutting surface but a flexible, strong body.

Difference Between Friction Welding and Friction Stir Welding

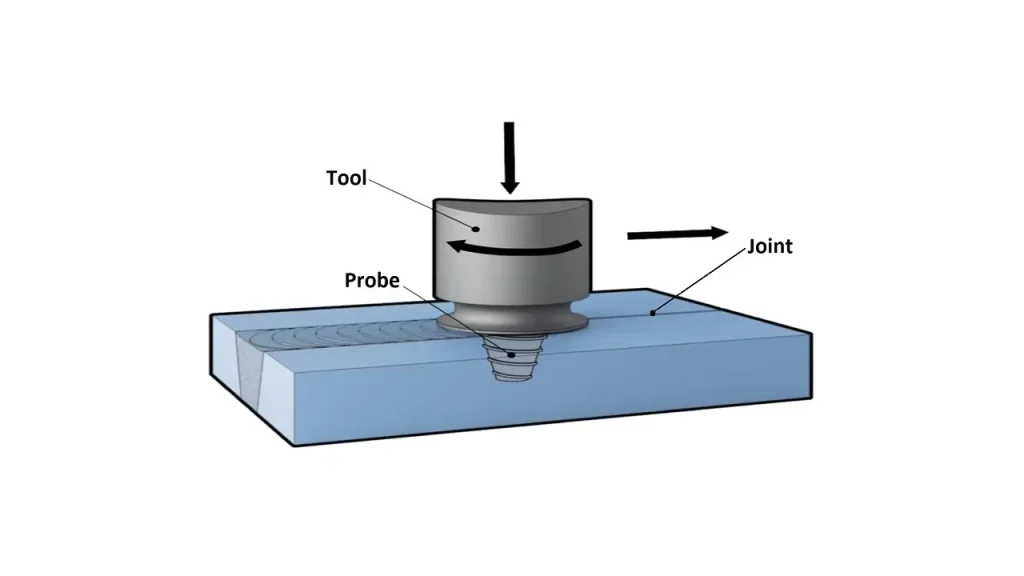

Friction welding and friction stir welding are both solid-state joining processes that create a bond without melting the base metals. However, they differ significantly in their mechanism, application, and the resulting joint characteristics.

Friction Welding

Friction welding is a rotational welding process used to join two components, typically with circular cross-sections (like drill rods). One piece is held stationary while the other is spun at high speed and pressed against it. The friction generates heat, making the material plastic and allowing it to be forged together. It’s ideal for creating a butt joint between two separate pieces.

- Mechanism: Rotational friction and forging pressure.

- Key Use: Creating strong, single joints between two components (e.g., joining tool joints to a drill rod body).

- Joint Type: Butt joints.

Friction Stir Welding

Friction stir welding (FSW) is a non-rotational process that uses a third piece—a rotating tool—to create the bond. The tool is plunged between the two pieces to be joined. The friction from the rotating tool heats the material, and the tool’s unique pin and shoulder stir and forge the plasticized material together. It’s primarily used for creating linear joints along the length of a piece of material.

- Mechanism: A separate rotating tool stirs and forges the material.

- Key Use: Creating long, seamless seams (e.g., joining two plates or sheets together).

- Joint Type: Linear lap or butt joints.

Conclusion

In conclusion, the adoption of friction welding in drill rod manufacturing is a significant leap forward in drilling technology. This process eliminates the weak heat-affected zones of traditional welding, resulting in rods with superior fatigue resistance and an extended service life. The strength and durability it provides directly translate to a lower cost per meter for any drilling operation.

The benefits of friction welding extend beyond just a stronger joint. It ensures optimal power transmission from the rig to the bit, leading to faster penetration and more consistent performance in the toughest rock formations. For any operation serious about productivity and long-term cost savings, friction-welded drill rods are an essential investment.

For fatigue-resistant drill rods built with the power of friction welding, look no further than Sinodrills. We specialize in providing wholesale friction-welded drill rods engineered for maximum performance and durability. Contact us today to get a quote and equip your team with the best tools for the job.