Selecting the right drill bit profile is a crucial decision that can significantly impact the success and efficiency of your drilling operation. From maximizing penetration rates to ensuring borehole stability, the profile—or shape of the bit’s face—is a key factor. This guide is designed to demystify the various drill bit profiles available, helping you understand how each one performs in different ground formations.

Whether you are working with soft shale, abrasive granite, or fractured rock, using a bit with the optimal profile is essential. A poorly matched profile can lead to premature wear, steering issues, and slower progress. This guide will walk you through the characteristics of popular bit profiles, including parabolic, flat, and concave, so you can make an informed choice for your next project.

What is Drill Bit Profile?

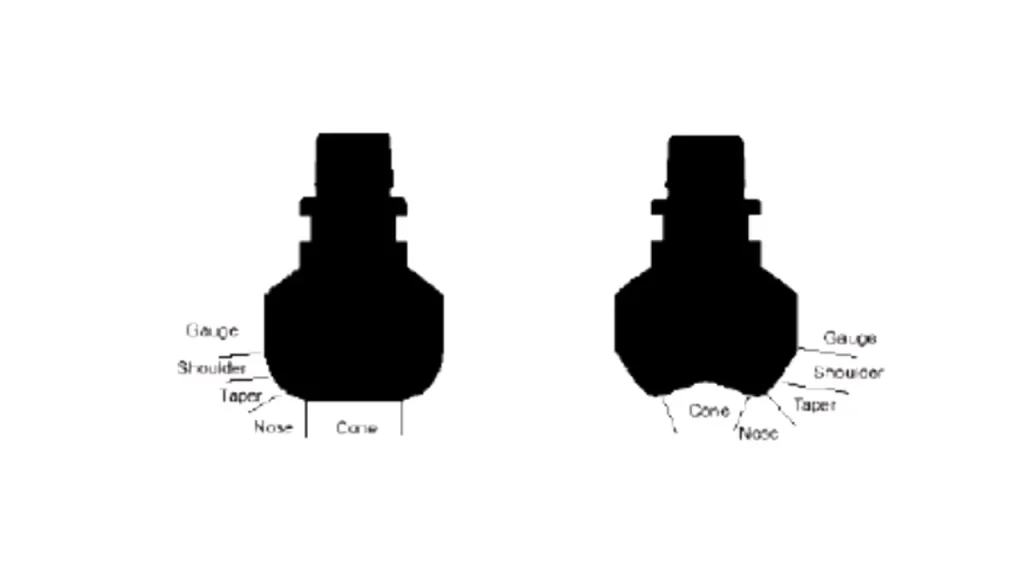

The drill bit profile refers to the overall shape and design of the bit’s cutting face and body. This is a critical feature because it determines how the bit interacts with the rock or soil it’s drilling through. Different profiles are engineered for specific applications and geological conditions, influencing factors like penetration rate, hole stability, and the ability to clear cuttings.

For instance, a long, parabolic profile is often used for soft formations, while a shorter, more compact profile is designed for harder, more abrasive rock. The profile works in concert with the cutting elements (like PDC cutters or roller cones) and the bit’s hydraulics to achieve optimal performance and minimize drilling costs.

Drill Bit Profile Types

A drill bit’s profile is the shape of its cutting face and body, a key design element that dictates its performance across various rock formations and drilling conditions. The profile is engineered to optimize penetration, stability, and cuttings removal. Choosing the right profile is essential for maximizing efficiency and minimizing costs.

Parabolic Drill Bit Profile

This long, rounded profile is excellent for drilling through soft, sticky formations like clay and shale. Its extended face enhances stability and guides cuttings away efficiently. The shape also reduces bit balling, a common issue in these specific formations, ensuring consistent performance.

Flat Drill Bit Profile

Designed with a short, compact cutting face, this profile is a go-to for drilling hard, abrasive, or fractured rock. Its robust design provides maximum strength and durability, minimizing wear in tough conditions. The flat profile delivers high impact force directly to the formation.

Concave Drill Bit Profile

Characterized by its inwardly curved face, this profile is ideal for directional drilling and maintaining a straight borehole. The concave shape centralizes the bit’s force, helping to stabilize the tool and prevent it from “walking” off course in formations of varying hardness.

Hemispherical Drill Bit Profile

This profile features a spherical, or half-ball, shape. It’s often used in roller cone bits and is known for its durability and resistance to breakage in very hard, non-abrasive rock. The shape distributes cutting forces evenly, leading to smooth drilling and long bit life.

Conical Drill Bit Profile

Conical profiles are defined by their cone-like shape and are used primarily in roller cone bits. They are highly effective in crushing and breaking up medium to hard formations. The design allows the cones to rotate and crush rock with significant force, ensuring high penetration rates.

Stepped Drill Bit Profile

This profile has a series of steps or “shelves” on its cutting face. It is commonly used in PDC bits for drilling through layered or interbedded formations, where alternating soft and hard layers are present. The steps help to manage the transition between layers smoothly.

Blade Drill Bit Profile

Used on drag bits, this profile is characterized by its simple, non-rotating blade design. It’s best suited for very soft, non-abrasive formations like sand and unconsolidated soil. The blades scrape away material rather than crushing or cutting it, making it highly effective.

Modified Parabolic Drill Bit Profile

A hybrid between the parabolic and flat profiles, this design offers versatility. It features a shorter, less aggressive curve than a full parabolic profile, making it suitable for a wider range of formations, from soft to moderately hard, while still maintaining good steering control.

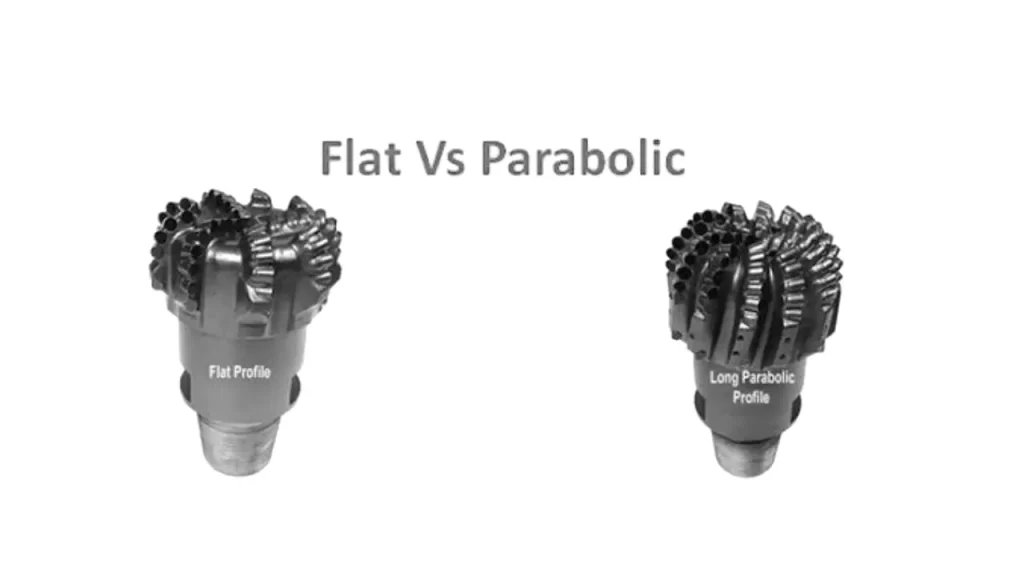

Flat vs Parabolic Drill Bit Profile

For PDC bits, the choice between a flat and a parabolic profile is a strategic decision based on the geology of the drilling environment. The profile, which refers to the overall shape of the bit’s cutting face, significantly impacts the bit’s stability, steering, and rate of penetration.

- Flat Profile: This profile has a short, aggressive face and is best suited for hard, abrasive, or fractured rock formations. It provides high durability and strength, concentrating the force on the cutters to crush the rock effectively. This profile is not ideal for soft, sticky formations as it can lead to bit balling.

- Parabolic Profile: Characterized by its long, rounded shape, a parabolic profile is highly effective in soft, plastic formations like shale and clay. The shape helps to clean the bit face by moving cuttings away, which prevents bit balling. However, this design can be less stable in very hard rock and is more prone to wear.

This video from a drilling engineer provides a foundational understanding of various drill bit profiles and their influence on performance.

How to Choose the Right Drill Bit Profile?

Choosing the right drill bit profile is a crucial step for achieving optimal drilling performance and a successful project. The best profile is determined primarily by the specific geological formation and the desired drilling outcome. To select the right drill bit profile for your project, you should consider:

- Geological Formation: The most important factor. For soft and sticky formations like clay or shale, a long parabolic profile is ideal to prevent bit balling and ensure efficient cuttings removal. For hard, abrasive, and fractured rock, a short, durable flat profile is better suited to withstand high impact forces.

- Drilling Application: The profile also depends on the type of job. A concave profile is excellent for maintaining a straight borehole and directional drilling, while a stepped profile is best for interbedded formations with alternating layers of soft and hard rock.

- Desired Outcome: Consider what you need to achieve. If you’re focused on high penetration rates in medium-to-hard rock, a conical profile might be the best choice. If a smooth, precise hole is your priority, a profile like the hemispherical may be more suitable.

This video can help you learn how to select a drill bit for your project.

Conclusion

In conclusion, mastering the art of selecting the correct drill bit profile is paramount to achieving superior drilling performance and project profitability. The right profile, whether it’s a parabolic, flat, or concave design, acts as a force multiplier, enhancing efficiency, extending tool life, and reducing operational costs. By understanding the unique strengths of each profile and matching it to your specific geological conditions, you are setting the stage for a successful and trouble-free drilling experience.

Furthermore, we believe that high-quality, reliable drill bits are the foundation of any successful drilling operation. Using durable, expertly engineered bits minimizes downtime and helps you meet project deadlines. By investing in bits with the optimal profile, you are not just buying a tool; you are investing in a seamless workflow and maximizing the return on your equipment.

Ready to upgrade your drilling tools? As a leading manufacturer, we offer a wide range of wholesale drill bits with various profiles to suit all your project needs. We provide competitive pricing on bulk orders, ensuring you get the best value without compromising on quality. Contact us today to get the best drill bits directly from the source and elevate your drilling performance.