Drilling through tough materials requires tools that can withstand incredible stress and friction. This is where carburized steel comes in. In this blog, we’ll explore what makes this material a game-changer for the drilling industry. We’ll uncover how a specialized heat treatment process transforms ordinary steel into an exceptionally hard and durable material.

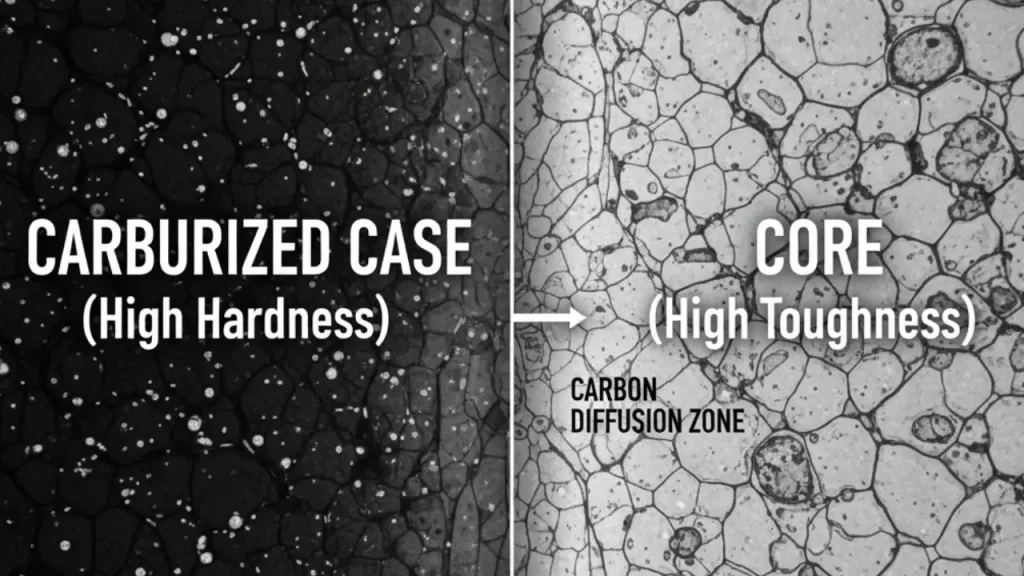

This process, known as carburizing, enriches the surface of the steel with carbon, creating a hard outer shell while the core remains tough and ductile. This unique combination of properties makes carburized steel drill rods resistant to wear and impact, ensuring they last longer and perform better under extreme conditions.

What is Carburized Steel?

Carburized steel is a type of steel that has undergone a heat treatment process called carburization to increase its surface hardness. This process involves heating low-carbon steel in a carbon-rich environment, which causes carbon atoms to diffuse into the surface layer of the metal.

The result is a dual-property material: a hard, wear-resistant outer case and a tough, ductile inner core. This combination of properties makes carburized steel ideal for applications that require a strong, durable surface to withstand wear and friction, while the core remains resilient against shock and impact.

Why Carburize Steel Matters for Drill Rods

Carburizing is essential for drill rods because it provides a unique combination of surface hardness and core toughness, which is critical for drilling applications. By enriching the surface with carbon, the drill rod develops a hard “case” that resists wear, abrasion, and heat, while the inner core remains relatively softer and more ductile.

This dual-property structure prevents the rod from becoming brittle and breaking under high stress, torque, and impact loads, which are common in mining, quarrying, and construction. The benefits include:

- Increased Wear Resistance: The hard outer case prevents the drill rod from wearing down quickly when drilling through abrasive rock and other tough materials, extending its lifespan.

- Enhanced Fatigue Strength: The combination of a hard surface and a tough core helps the rod withstand repeated stress cycles without failing, which is crucial for deep and demanding drilling operations.

- Greater Durability: Carburized steel drill rods are far less prone to chipping or cracking compared to fully hardened steel, making them reliable and safer to use in challenging geological conditions.

How to Carburize Drill Rods?

Carburizing drill rods is a specialized heat treatment process that hardens the outer surface of the steel, making it highly resistant to wear and abrasion while maintaining a tough, flexible core. This process enhances the durability and performance of the drill rods for demanding applications.

Step 1: Cleaning and Preparation

First, the drill rods are thoroughly cleaned to remove any dirt, oil, or grease. This is crucial because a clean surface ensures even and consistent carbon absorption during the heating phase, which is essential for a uniform hardened case. Any surface contaminants can prevent the carbon from properly diffusing into the steel. A clean, prepared surface guarantees that the final product has the desired hardness and strength properties.

Step 2: Carburizing

Next, the cleaned drill rods are placed in a furnace and heated to high temperatures, typically between 850°C and 950°C. The furnace atmosphere is enriched with carbon-bearing gases like methane or propane, causing carbon atoms to diffuse into the steel’s surface. The rods are held at this temperature for a specific period to achieve the desired case depth. This stage is carefully controlled to ensure the carbon penetrates to the correct depth without affecting the core’s integrity.

Step 3: Quenching

Following the carburizing phase, the hot drill rods are rapidly cooled in a process called quenching. They are typically submerged in a liquid medium like oil or a polymer solution. This rapid cooling locks the carbon in place, transforming the surface into a hard martensitic structure. The speed of the quenching process is critical to prevent the carbon from migrating and to achieve maximum surface hardness. Proper quenching ensures the drill rod’s outer layer is incredibly durable.

Step 4: Tempering

Finally, the quenched drill rods undergo tempering. They are reheated to a lower temperature, around 150°C to 250°C, and then slowly cooled. This final step is vital for relieving internal stresses and reducing the brittleness caused by quenching. Tempering slightly decreases the hardness but significantly increases the toughness and impact resistance of the drill rods. This makes them less prone to cracking or chipping during high-stress drilling operations.

Why Choose Our Carburized Drill Rods?

Our carburized drill rods are the premier choice for professionals who demand the best in performance and durability. Unlike standard drill rods, our products undergo a meticulously controlled carburization process that creates a super-hard, wear-resistant outer case while leaving the core tough and flexible.

This unique combination of properties makes our drill rods exceptionally suited for the most challenging drilling conditions, from hard rock to abrasive formations. We are committed to providing tools that not only meet but exceed industry standards, ensuring you achieve maximum productivity and a lower cost per meter drilled.

- Superior Wear Resistance: The case-hardened surface significantly prolongs the rod’s lifespan, reducing the need for frequent replacements.

- Exceptional Impact Strength: The tough core absorbs shock and impact, preventing brittle fracture and ensuring reliability in high-stress applications.

- Optimized Performance: Our manufacturing process guarantees superior energy transmission from the rig to the bit, leading to faster penetration rates and more efficient drilling.

- Reduced Operational Costs: The longevity and efficiency of our carburized drill rods lower overall project expenses and increase your return on investment.

Conclusion

In conclusion, carburized steel is the key to unlocking superior performance and longevity in drill rods. By creating a case-hardened surface, the carburizing process provides unmatched wear resistance, while maintaining a ductile core that prevents brittle failure. This technology ensures that drill rods can handle the most demanding drilling applications with ease.

The durability and extended lifespan of carburized drill rods not only reduce operational costs but also improve efficiency on the job. You can trust that these tools will consistently deliver reliable results, minimizing downtime and maximizing productivity for your projects. This makes them a wise investment for any professional drilling operation.

If you’re looking to equip your team with the best tools, consider the advantages of wholesale carburized drill rods from Sinodrills. Our products are engineered for excellence, offering the perfect blend of hardness and toughness. Contact us today to get the durable, high-performance drill rods you need to succeed.