Custom Concentric Casing System With Ring Bit Manufacturer in China

As a leading manufacturer of custom concentric casing systems with ring bits in China, we offer tailored solutions to meet your project’s unique demands. We provide specialized ring bits, pilot bits, and casings in various sizes and materials, ensuring optimal performance in any ground condition. Our expertise guarantees a precise, efficient, and reliable system for your drilling needs.

Sinodrills - Your Trusted Concentric Casing System With Ring Bit Manufacturer from China

Sinodrills is your trusted manufacturer from China, specializing in concentric casing systems with ring bits. We are committed to providing premium, customizable drilling solutions designed to tackle the toughest ground conditions. With our advanced manufacturing and engineering expertise, we ensure superior performance, durability, and a lower per-meter drilling cost for all your overburden drilling projects.

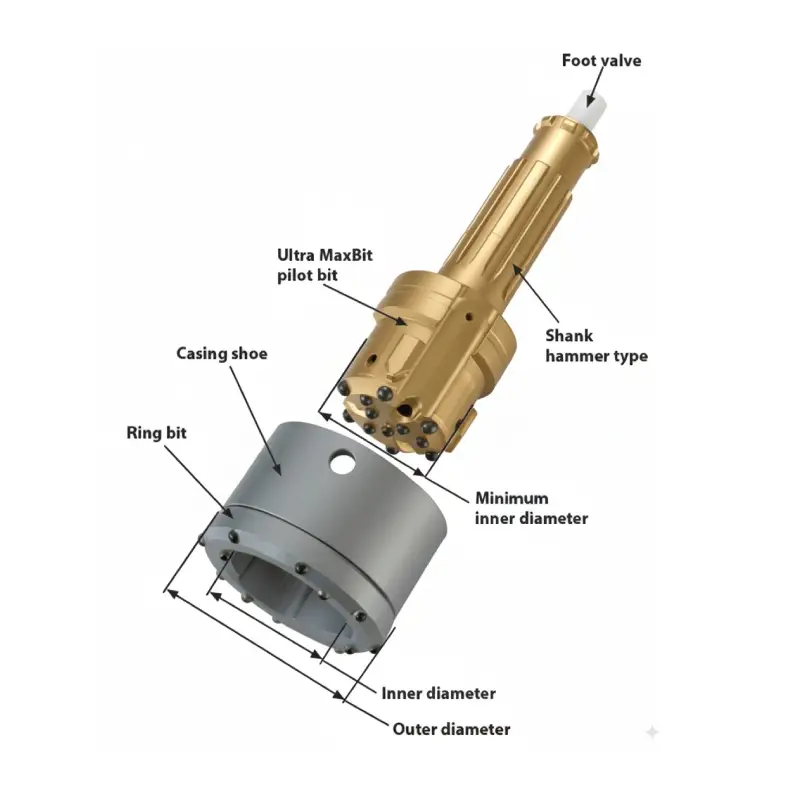

Concentric Casing System With Ring Bit Structure

Pilot Bit: This is the central, sacrificial drill bit that initiates the hole. It guides the entire assembly and transfers the percussive energy from the hammer.

Ring Bit: This is the outer reaming bit that widens the hole to accommodate the casing. It is locked onto the pilot bit and drives the casing into the ground.

Casing Shoe: This part is a steel ring welded to the bottom of the casing pipe. It provides a cutting edge and a shoulder for the ring bit to push against.

Casing Pipe: The pipe itself, which is a key structural element. It is driven into the ground to permanently line the borehole.

Concentric Casing System With Ring Bit Applications

Water Well & Geothermal Drilling: Ensures the integrity of the wellbore in unstable geological formations, which is crucial for long-term well performance and preventing contamination.

Foundation and Piling: Utilized for creating stable foundations, micropiles, and anchors for construction projects in difficult ground conditions with loose soil or boulders.

Environmental & Geotechnical Projects: Ideal for installing monitoring wells, soil sampling, or site investigation in areas where a stable, cased hole is required for accurate data collection.

Mining and Quarrying: Used for applications requiring permanent or retrievable casing in various rock and overburden formations, improving safety and operational efficiency.

Tunneling and Horizontal Drilling: Provides ground support ahead of the main tunnel face, and is used for creating pilot holes and installing rock anchors in challenging subsurface conditions.

Various Concentric Casing System With Ring Bit

Concentric Casing System With Ring Bit benefits

Hole Integrity: The system stabilizes the borehole as it drills, preventing collapse in loose soil, gravel, and boulder formations. This ensures a clean and secure final hole.

Increased Efficiency: By combining two steps into one, this system drastically reduces drilling time and labor costs. It eliminates the need to pull out the drill string to run casing separately.

Reduced Deviation: The full-face design provides superior guidance, drilling a straighter hole with minimal deviation, which is crucial for precision projects like piling and anchoring.

Lower Torque & Vibration: Compared to eccentric systems, the concentric design requires less torque and causes less vibration, reducing wear and tear on the drilling rig and improving operator comfort.

casing advancement systems for down-the-hole hammers

Casing advancement systems for down-the-hole (DTH) hammers offer significant benefits by simultaneously drilling and installing casing. This integrated process is especially advantageous when working in unstable ground conditions prone to collapse. By combining two operations into one, these systems enhance safety, efficiency, and overall project success.

Increased Efficiency & Speed: Combining the drilling and casing processes into a single operation drastically reduces overall project time and labor costs. This eliminates the need to pull out the drill string to run casing, minimizing downtime and accelerating well completion.

Enhanced Borehole Stability: The continuous installation of casing prevents the borehole walls from caving in, a common problem in loose or fractured ground. This ensures a stable, clean, and secure hole from start to finish.

Improved Safety: By preventing hole collapse and reducing the number of trips down the hole, these systems lower the risk of tool entrapment and other hazards for workers. This leads to a safer working environment.

Reduced Deviation: The concentric design provides superior guidance, drilling a straighter hole with minimal deviation. This is crucial for precision projects like piling and anchoring where accuracy is essential to the structural integrity of the final product.

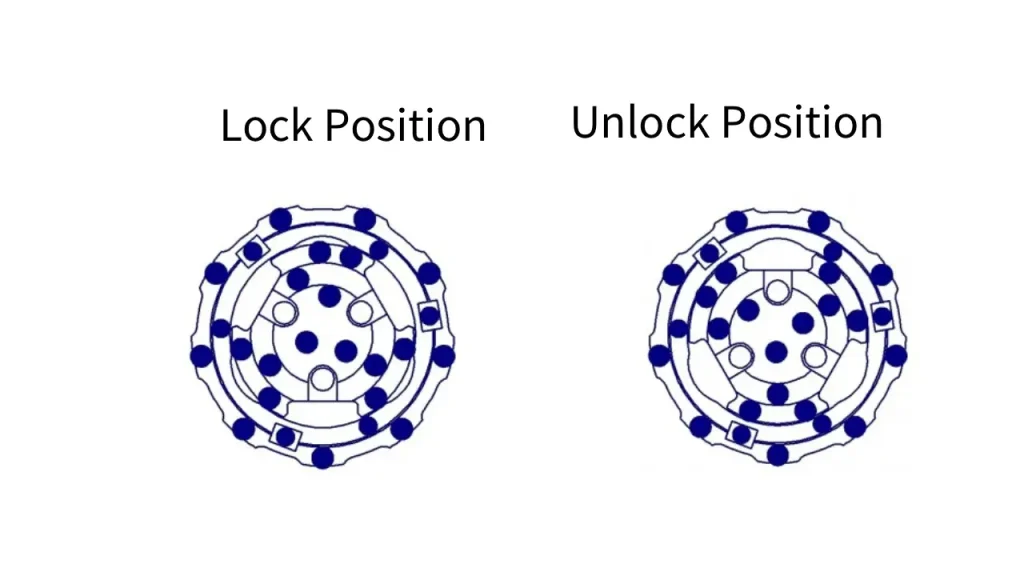

Locking and Unlocking Position

The core functionality of a concentric casing system with a ring bit lies in its ingenious locking and unlocking mechanism, which allows the pilot bit to drive the ring bit and casing during drilling and then be retrieved once the desired depth is reached. This is typically achieved through a bayonet-style coupling that uses a simple rotational action to engage and disengage the components.

Locking: To lock the system, the pilot bit is inserted through the casing and into the ring bit assembly. A slight clockwise rotation of the drill string locks the pilot and ring bits together. In this locked position, the hammer’s percussive energy and rotational torque are transferred from the pilot bit to the ring bit and then to the casing, enabling all components to drill and advance as a single, cohesive unit.

Unlocking: Once drilling is complete, a slight reverse (counter-clockwise) rotation of the drill string unlocks the pilot bit from the ring bit. This action separates the pilot bit from the rest of the assembly, allowing the drill string to be pulled out of the hole, leaving the ring bit and casing permanently in place to line the borehole. The ability to retrieve the pilot bit allows for further drilling into bedrock with a conventional bit if needed.

Customize Your Desired Concentric Casing System With Ring Bit

The Full-Face Design

We utilize a full-face design where the central pilot bit and the outer ring bit work together as one cohesive unit. This ensures superior guidance and penetration, delivering a straighter hole with minimal deviation, which is crucial for applications like foundation piling and anchoring.

The Locking and Unlocking Mechanism

We engineer a reliable locking mechanism that securely connects the pilot bit and the ring bit, allowing percussive and rotational energy to transfer efficiently. This design also allows for easy unlocking and retrieval of the pilot bit, leaving the ring bit and casing in the hole.

Flushing and Hole Cleaning

We integrate optimized internal flushing grooves and air holes into the system. This design ensures that all cuttings and debris are effectively evacuated through the casing, which minimizes the risk of hole blockage and allows the tool to run smoothly, increasing its lifespan.

The Sacrificial Ring Bit

We offer both permanent and retrievable ring bit designs to suit specific project needs. For permanent applications, the ring bit is left in the hole to serve as the casing shoe, while the retrievable version allows us to recover the ring bit after use, providing a more cost-effective solution.

All-in-one Concentric Casing System With Ring Bit Solutions for Your Project

We offer all-in-one concentric casing system solutions designed for your project. Our systems are fully customizable, including tailored ring and pilot bits, and casings in a range of materials and diameters. We ensure seamless integration with your rig, providing a complete and reliable solution for drilling in unstable ground conditions with maximum efficiency and stability.