Choosing the right rock bolt is crucial for the safety and stability of any geotechnical or mining project. With a variety of types available, each with unique functions and applications, making an informed decision can be complex. This guide will simplify the process, helping you understand the different options.

This article will explore the most common types of rock bolts, including mechanical, grouted, and self-drilling anchors. By understanding their specific characteristics and benefits, you can select the perfect anchor to match your project’s unique geological conditions and operational requirements.

What are Rock Bolts?

A rock bolt is a long steel rod used in geotechnical engineering to stabilize and reinforce rock excavations and formations. Essentially, it functions as a deep anchor, transferring load from the unstable, exposed exterior of a rock mass to its more confined and stable interior.

This process, known as rock bolting, enhances the overall shear strength and stability of the rock by “knitting” together loose or fractured layers into a single, unified, load-bearing structure. Rock bolts are an indispensable component in the construction of tunnels, mines, and slopes, where they are installed to prevent collapses and ensure long-term structural integrity.

Types of Rock Bolts

Recommended Rock Bolts

Selecting the correct rock bolt is essential for ensuring the stability and safety of a project. Various types of rock bolts exist, each designed for specific ground conditions and applications. Understanding the characteristics of each bolt type is key to making an informed decision that will guarantee project success and longevity.

Self-Drilling Rock Bolt

Self-drilling rock bolts, also known as hollow bars, are designed for simultaneous drilling and grouting. They are particularly effective in difficult ground conditions, such as broken rock or loose soil, where conventional drilling methods would cause the borehole to collapse. This all-in-one system increases efficiency and reduces installation time.

The hollow core allows for the injection of grout or resin through the bolt itself, which fills the surrounding voids and creates a strong, continuous bond with the rock mass. This enhances the bolt’s load-bearing capacity and provides excellent protection against corrosion, making it a reliable choice for both temporary and permanent applications in complex geology.

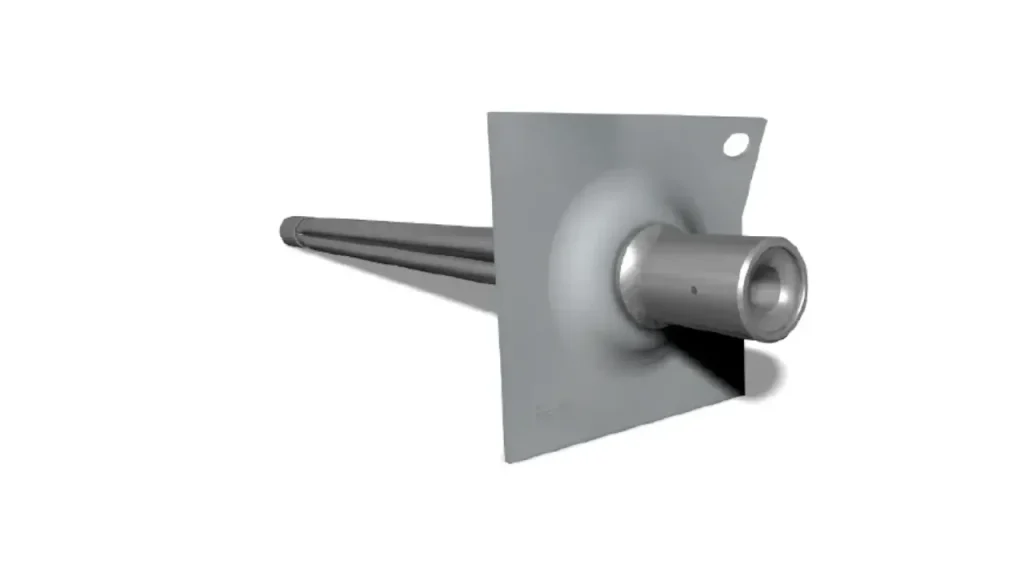

Expansion Shell Hollow Rock Bolt

Expansion shell hollow rock bolts use a mechanical system to anchor themselves within the rock. The bolt features an expansion shell at one end which, upon installation, expands and presses against the borehole wall. This creates a secure grip that provides immediate and high-capacity support.

These bolts are highly effective in hard, competent rock where a secure mechanical lock can be achieved. They are commonly used in civil engineering and mining for temporary and permanent support where high load-bearing capacity is required and can be tensioned after installation to provide active support to the rock mass.

Swellex Rock Bolt

Swellex rock bolts are a unique type of friction rock bolt that relies on hydraulic expansion. The bolt consists of a folded steel tube that is inserted into a pre-drilled borehole. High-pressure water is then injected into the tube, causing it to expand and conform to the irregular shape of the borehole. This creates a strong frictional bond along its entire length.

This method of installation is very fast and safe, as it eliminates the need for grouting and can be performed quickly in a variety of conditions. Swellex bolts are particularly well-suited for ground conditions where immediate and full-length support is necessary, such as in tunnels and underground chambers.

Rock bolts can be categorized based on their mechanism of support and installation method. Below is a table detailing the key differences and applications of various types of rock bolts.

| Type of Rock Bolt | Support Mechanism | Best for Rock Condition | Installation Method | Key Feature |

| Mechanical Anchor | Active (tensioned) | Hard, competent rock | Drilled hole, bolt inserted and mechanically expanded | Provides immediate, high-capacity support; can be re-tensioned |

| Grouted (Fully Bonded) | Passive | Fractured, competent to weak rock | Drilled hole, resin or cement grout secures the bolt | Provides long-term, full-length support; great for complex geology |

| Friction (e.g., Split Set, Swellex) | Passive (friction) | Weak to medium rock | Drilled hole slightly smaller than bolt diameter; relies on friction | Quick, easy to install; provides immediate support along the full length |

| Self-Drilling Anchor | Active and Passive | Unstable, collapsing ground | Simultaneously drills, injects grout, and installs the anchor | All-in-one process; ideal for difficult ground; no separate drilling step |

| Cable Bolt | Active/Passive | Large rock masses, deep support | Drilled hole, multi-strand steel cables are grouted in place | Used for large-scale stabilization; high tensile strength |

How Each Type of Rock Bolt Provides Support

A mechanical anchor bolt provides active support by being tensioned after installation. The tension creates a compressive force in the rock, which increases its stability. This is ideal for hard rock where the anchor can be securely locked.

A grouted rock bolt, on the other hand, is a passive support system. It is fully bonded to the surrounding rock with a grout or resin, which solidifies over time. It provides support by resisting any shear or tensile movement of the rock mass after the grout has set.

Friction bolts are also passive, relying entirely on the radial pressure exerted on the borehole walls. When installed, they expand against the rock, providing immediate frictional resistance to any rock mass movement.

Self-drilling anchors offer a unique, dual-support mechanism. They are considered active because they are often tensioned, but they also provide passive support from the grout that is injected simultaneously with drilling, which bonds the entire length of the bolt to the rock.

How to Choose Suitable Rock Bolts?

Choosing the right rock bolt is a critical decision that depends on a comprehensive analysis of the project’s specific geological conditions, design requirements, and budget. There is no one-size-fits-all solution, as a bolt that works well in one type of rock may be ineffective in another. The selection process requires a systematic approach to ensure the chosen anchor provides the necessary support while remaining cost-effective and easy to install.

- Geological Conditions: The most important factor is the rock mass itself. You must consider the rock’s strength, degree of fracturing, and presence of water or corrosive elements. A competent, hard rock may be suitable for a mechanical anchor, while highly fractured or weak rock may require a self-drilling or fully grouted bolt.

- Project Requirements: The purpose of the rock bolt is key. Is it for temporary support in a shallow excavation or for permanent stabilization of a deep tunnel? Temporary bolts can be simpler and less expensive, while permanent bolts require more robust corrosion protection and long-term durability.

- Support Mechanism: You must decide whether you need an “active” or “passive” support system. Active bolts, like tensioned mechanical anchors, provide immediate reinforcement. Passive bolts, like fully grouted dowels, provide support only after some ground movement occurs.

- Installation Method: The site conditions and available equipment will influence the choice. In confined spaces or unstable ground, a self-drilling anchor that combines drilling and grouting can be far more efficient than a traditional two-step process.

- Cost and Budget: Finally, the overall budget will play a role. While higher-quality or more specialized bolts may have a higher initial cost, they can often save money in the long run by reducing installation time, preventing ground failure, and minimizing maintenance.

Conclusion

In conclusion, the selection of a rock bolt is a critical engineering decision that directly impacts the safety and success of your project. By carefully considering the ground conditions, project requirements, and the specific advantages of each bolt type, you can ensure you choose the most effective and reliable solution for long-term stability.

Understanding the differences between active and passive support systems, and the roles of mechanical, grouted, and self-drilling anchors, empowers you to make a professional and confident choice. The right anchor not only provides necessary support but also contributes to overall project efficiency and cost-effectiveness.

For your next project, trust Sinodrills for wholesale self-drilling anchor bolts. Our bolts are engineered for superior performance and durability, providing a streamlined, all-in-one solution for drilling, grouting, and anchoring. Choose our reliable products for a safer and more efficient construction process.