Custom Concentric Casing System With Wings Manufacturer in China

We are a leading manufacturer in China offering custom concentric casing systems with wings, designed for reliable well construction and drilling operations. Our systems provide enhanced stability, easy installation, and precise alignment. Tailored to meet specific project requirements, we deliver durable, efficient, and cost-effective solutions that improve drilling performance across various geological conditions.

Sinodrills - Your Trusted Concentric Casing System With Wings Manufacturer from China

Sinodrills is your trusted manufacturer in China for concentric casing systems with wings. We provide custom solutions designed for stability, precise alignment, and efficient well construction. Our durable and reliable systems are tailored to meet diverse project requirements, ensuring improved drilling performance, easy installation, and cost-effective solutions for various geological and industrial applications.

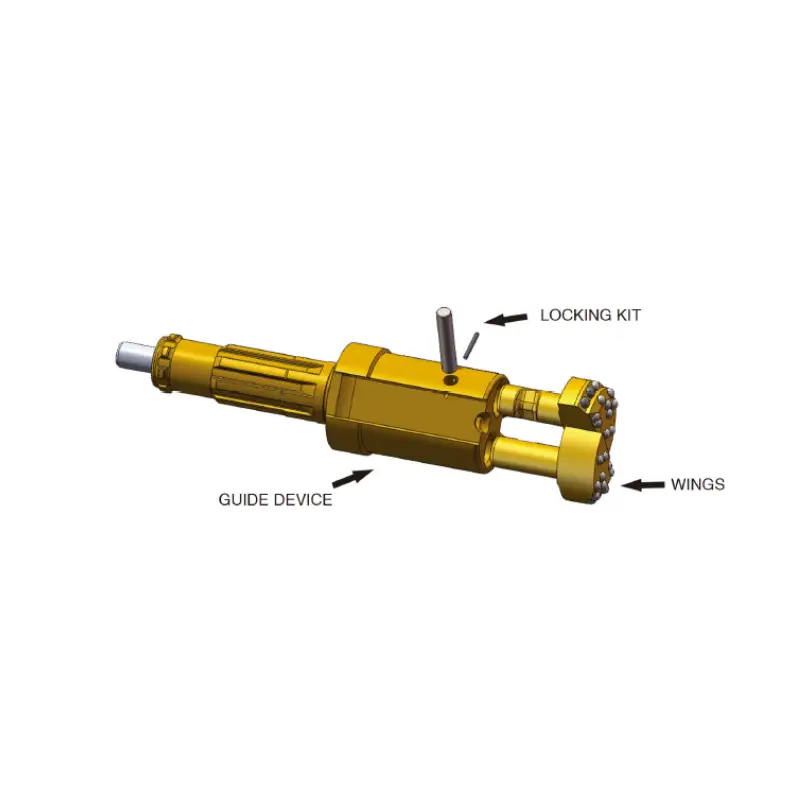

Concentric Casing System With Wings Component

Outer Casing: The outer casing provides structural support and stability for the system, maintains wellbore integrity, protects inner components, and ensures safe, efficient drilling operations.

Inner Casing: The inner casing fits concentrically within the outer casing, guiding the drill string and fluids, ensuring alignment, preventing collapse, and supporting smooth drilling performance.

Wing Plates: Wing plates extend from the casing body, stabilizing the system in the wellbore, resisting rotation and lateral movement, enhancing drilling accuracy, and reducing operational risks.

Centralizers: Centralizers keep the casing concentric and centered, reduce friction, improve cementing efficiency, and ensure uniform spacing for optimal wellbore stability during drilling operations.

Sealing Elements: Sealing elements like gaskets or O-rings prevent fluid leakage between casing sections, maintain pressure control, and protect both equipment and surrounding geological formations.

Connection Joints: Connection joints securely link casing sections, provide structural continuity, allow safe installation and retrieval, and ensure proper alignment and durability during drilling operations.

Concentric Casing System With Wings Benefits

Enhanced Wellbore Stability: The wing design stabilizes the casing within the wellbore, reducing lateral movement and collapse risks, ensuring consistent structural integrity throughout drilling operations.

Improved Drilling Accuracy: Wings and centralizers maintain precise alignment of the casing, guiding the drill string effectively, minimizing deviation, and achieving accurate well placement.

Efficient Installation: The system’s modular design and wing features allow faster and safer installation, reducing operational time and labor costs while ensuring reliable performance.

Reduced Equipment Wear: Proper stabilization and alignment reduce stress and friction on drill strings and casings, extending the life of both equipment and tooling.

Versatile Application: Suitable for various geological formations, the system adapts to different well conditions, providing consistent performance across mining, construction, and industrial drilling projects.

Cost-Effective Operations: By enhancing stability, accuracy, and equipment longevity, the system lowers operational risks, reduces downtime, and ultimately decreases overall drilling costs.

Concentric Casing System With Wings Applications

Oil and Gas Drilling: Used in oil and gas wells to maintain wellbore stability, improve alignment, and ensure efficient drilling operations under varying geological conditions.

Water Well Construction: Supports safe and precise water well drilling, preventing collapse and ensuring proper casing alignment for long-lasting and reliable water supply systems.

Mining Operations: Provides structural stability in mining boreholes, allowing safe extraction of minerals while reducing equipment wear and operational risks during deep rock drilling.

Geotechnical Investigation: Essential in soil and rock sampling, monitoring, and testing. It ensures accurate core recovery and maintains borehole integrity for engineering and geological analysis.

Infrastructure Projects: Applied in tunnels, bridges, and foundation drilling, offering reliable support for underground construction, maintaining alignment, and ensuring safety during complex civil engineering works.

Customize Your Desired Concentric Casing System With Wings

Size and Diameter

We customize the size and diameter of concentric casing systems with wings to match your project’s wellbore specifications. By adjusting dimensions, we ensure proper alignment, efficient installation, and enhanced stability, providing reliable performance for drilling operations in various geological conditions.

Wing Design and Placement

We tailor the wing design and placement to optimize stabilization and prevent lateral movement. By adjusting the shape, length, and angle of wings, we enhance wellbore support, improve drilling accuracy, and reduce operational risks for different soil and rock formations.

Material Selection

We offer customization in material selection for casing systems, including steel grades and corrosion-resistant alloys. Choosing the right material ensures durability, strength, and longevity, allowing the system to withstand extreme pressures, abrasive conditions, and demanding drilling environments.

Connection and Sealing Options

We design connection joints and sealing elements according to your operational requirements. By customizing threads, couplings, and seals, we ensure secure installation, prevent fluid leakage, and maintain structural integrity throughout drilling and well construction processes.

what is Concentric Drilling System?

A concentric drilling system is a drilling setup where the drill string, casing, and tooling are aligned along a single central axis. This design ensures precise wellbore placement, maintains stability in the borehole, and allows efficient transfer of torque and drilling fluids. It is widely used in oil, gas, water wells, and geotechnical projects for accurate and safe drilling operations.

what are benefits of Concentric Drilling System with wings?

A concentric drilling system with wings offers superior stability, precise alignment, and efficient drilling performance. The wings help maintain borehole integrity, reduce deviation, and enhance operational safety. This system is ideal for oil, gas, water well, and infrastructure drilling projects across various geological conditions.

Improved Borehole Stability: The wings stabilize the casing within the wellbore, reducing lateral movement and collapse risks, ensuring the borehole remains aligned and structurally sound even in challenging soil or rock formations.

Enhanced Drilling Accuracy: Concentric alignment with wings keeps the drill string centered, improving penetration precision, reducing deviations, ensuring accurate well placement, and optimizing operational efficiency while minimizing rework and project delays.

Reduced Equipment Wear: Stable and aligned drilling lowers stress on drill bits, rods, and casing, preventing premature wear, prolonging equipment life, reducing maintenance costs, and supporting consistent performance over extended drilling operations.

Safety and Operational Efficiency: By minimizing borehole instability and deviations, the system reduces accident risks, ensures efficient installation, improves project completion times, and enhances overall safety standards during drilling operations.

Adaptable to Various Geological Conditions: The wings and customizable design allow the system to handle different rock hardness and soil types, providing consistent performance and making it suitable for oil, gas, water wells, and infrastructure projects.

where to use Concentric Drilling System with wings?

Concentric drilling systems with wings are designed to provide precise alignment, borehole stability, and efficient drilling performance.

They are suitable for a wide range of applications where accuracy, safety, and reliable well construction are critical.

Oil and Gas Wells: Ideal for drilling oil and gas wells, the system maintains wellbore integrity, supports deep and precise drilling, reduces deviations, and ensures stable and efficient extraction operations.

Water Well Construction: Used in water well drilling, it provides accurate alignment, prevents borehole collapse, and ensures long-lasting, reliable water supply infrastructure with minimal maintenance and operational risks.

Mining and Mineral Exploration: In mining projects, the system stabilizes boreholes, improves drill accuracy, and supports safe extraction of minerals, reducing equipment wear and enhancing overall operational efficiency.

Infrastructure Projects: Applied in tunnels, bridges, and foundation drilling, it ensures stable boreholes, accurate placement, and safe installation for civil engineering works across various geological conditions.

Geotechnical and Environmental Drilling: Used for soil and rock sampling, environmental monitoring, and groundwater assessment, it maintains borehole integrity, allows precise data collection, and supports safe, reliable field operations.

Send Your Inquiry Now

All-in-one Concentric Casing System With Wings Solutions for Your Project

We provide all-in-one concentric casing system with wings solutions tailored to your project needs. Our systems offer enhanced stability, precise alignment, and easy installation, ensuring efficient well construction. Designed for diverse geological conditions, they combine durability, reliability, and customization options, delivering cost-effective, safe, and high-performance drilling solutions for oil, gas, water, and infrastructure projects.