A drill bit gauge pad is a crucial component in drilling operations, designed to maintain the stability and alignment of the drill bit. It ensures accurate hole sizes, reduces wear on the bit, and improves overall drilling efficiency, making it essential for mining, construction, and infrastructure projects.

Understanding the function of a drill bit gauge pad helps operators select the right bit for specific drilling tasks. It supports the drill bit during penetration, controls vibration, and enhances precision, ultimately reducing equipment damage and operational downtime. Proper use of gauge pads ensures safer, more efficient drilling across various rock formations and materials.

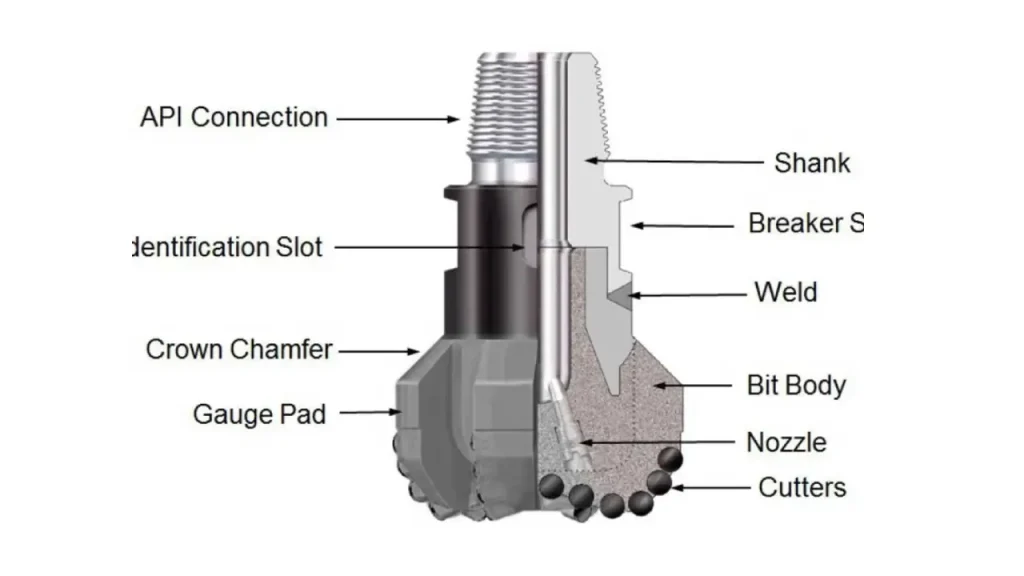

What is Drill Bit Gauge Pad?

A drill bit gauge pad is a key component used in drilling operations to maintain the stability and alignment of the drill bit. It helps ensure accurate hole sizes, reduces vibration, and minimizes wear on the bit, improving overall drilling efficiency.

Gauge pads are essential for various applications, including mining, construction, and infrastructure projects. They support precise drilling, enhance bit longevity, and contribute to safer, more efficient operations by keeping the drill bit properly positioned throughout the drilling process.

Functions of Drill Bit Gauge Pad

A drill bit gauge pad performs several key functions that improve drilling performance and precision. By stabilizing the bit and controlling its movement, it helps achieve consistent hole sizes and reduces equipment wear. Key functions include:

- Stabilizing the Drill Bit: The gauge pad keeps the drill bit aligned during drilling, preventing wobbling and uneven penetration. This stabilization reduces wear on both the bit and drilling equipment, resulting in longer service life and smoother operation across different rock formations.

- Controlling Vibration: Gauge pads help absorb and minimize vibrations generated during drilling. By reducing vibration, they improve drilling accuracy, protect the bit structure, and enhance operational safety, allowing operators to maintain steady, precise drilling performance in demanding conditions.

- Maintaining Hole Size: The pad ensures the drilled hole remains consistent in diameter. This accuracy is critical in applications like mining and construction, where precise hole dimensions are required for proper blasting, anchoring, or installation of infrastructure components.

- Improving Drilling Efficiency: By providing stability and reducing friction, the gauge pad allows faster penetration rates while minimizing energy consumption. This leads to higher productivity, less downtime, and more cost-effective drilling operations overall.

- Extending Bit Life: The consistent support and vibration control offered by the gauge pad reduce uneven wear on the bit. This prolongs the life of the drill bit, saving replacement costs and ensuring reliable performance in long-term drilling projects.

How to Choose Drill Bits?

Selecting the right drill bit is essential for efficient, precise drilling. The correct choice depends on material type, hole size, drilling depth, and operational conditions. Using the proper bit reduces wear, improves performance, and ensures safety during mining, construction, or infrastructure projects.

- Consider Material Compatibility: Choose a drill bit designed for the specific material being drilled, such as rock, concrete, or metal. Material-appropriate bits prevent premature wear, ensure smoother penetration, and reduce the risk of bit breakage, ultimately improving drilling efficiency and maintaining project timelines.

- Select the Right Size: Drill bit size must match the required hole diameter and depth. Using the correct size ensures proper fit, prevents oversized or undersized holes, and avoids unnecessary stress on the drilling equipment, enhancing both accuracy and operational safety.

- Check Bit Type: Different drilling tasks require specific bit types, such as PDC, carbide, or step-face bits. Choosing the right type improves cutting efficiency, stability, and durability, while minimizing energy consumption and the need for frequent bit replacements.

- Evaluate Drilling Conditions: Consider factors like rock hardness, moisture, and temperature. Bits suited for the specific environment perform more reliably, reduce downtime, and extend the life of both the drill bit and associated equipment, ensuring consistent drilling results.

- Review Bit Quality and Design: Focus on bit design features like gauge pads, cutting structure, and core support. Proper design enhances stability, vibration control, and precision, resulting in safer operations and higher productivity across all drilling applications.

Conclusion

Drill bit gauge pads play a vital role in maintaining drilling accuracy and extending bit life. By stabilizing the drill bit and controlling vibrations, they enhance performance and efficiency in challenging drilling conditions. Choosing the right gauge pad can significantly improve operational outcomes and reduce maintenance costs.

Incorporating drill bit gauge pads into your drilling setup ensures consistent hole sizes and better penetration rates. They contribute to safer operations by minimizing unexpected bit deviations and equipment stress. For businesses focused on mining, construction, or infrastructure drilling, these pads are a practical investment for long-term efficiency.

For those looking to equip their operations with reliable drill bits, Sinodrills offers wholesale options tailored to various drilling needs. Our products provide durability, performance, and precision, making it easy to source the right drill bits and gauge pads for any project while maintaining cost-effective solutions.