Geotechnical exploration is the bedrock of safe and sustainable construction, demanding accurate and efficient methods to understand subsurface conditions. Among the various drilling techniques, air rotary drilling stands out for its remarkable speed and versatility in penetrating diverse geological formations.

This blog delves into how air rotary drilling revolutionizes geotechnical investigations, offering significant efficiencies in data collection. We’ll explore its core principles, key advantages, and why it’s increasingly becoming the preferred method for engineers and geologists alike.

What is Air Rotary Drilling?

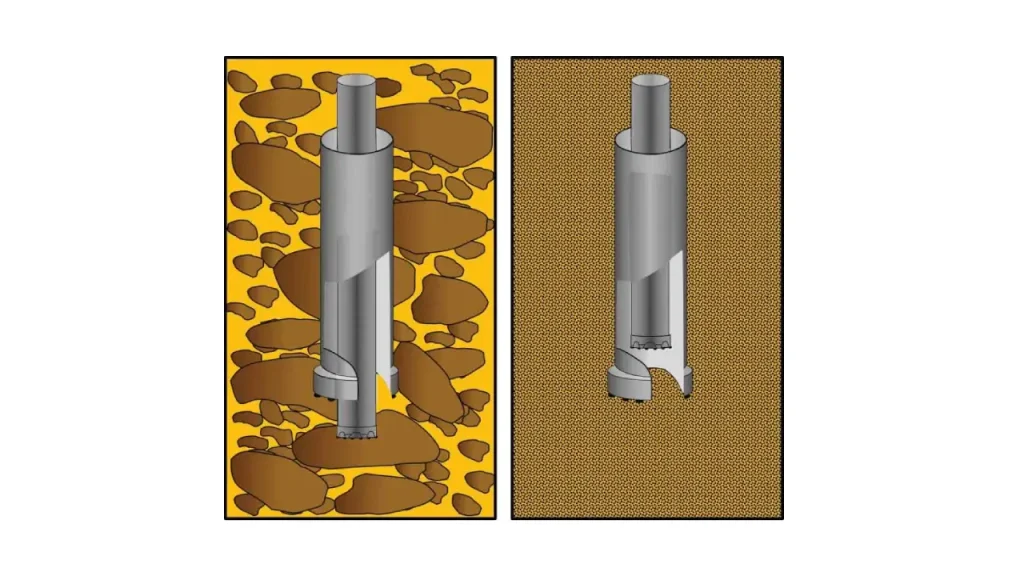

Air rotary drilling is a highly efficient and versatile wellbore excavation method primarily used for drilling deep boreholes in rock formations. It operates by rapidly rotating a drill bit, which cuts or crushes the rock into small pieces called cuttings.

Crucially, compressed air is then injected down the drill pipe, serving several key functions: it cools the spinning drill bit, provides pressure to stabilize the borehole walls and prevent collapse, and, most importantly, it flushes the rock cuttings back to the surface.

This continuous removal of cuttings allows for faster penetration rates and produces cleaner samples, making it a preferred choice for geotechnical exploration, environmental sampling, and water well drilling, especially in hard rock.

Why Air Rotary Drilling Method?

The choice to utilize the air rotary drilling method often hinges on the specific geological conditions and project objectives. This technique excels in formations where other drilling methods might struggle or prove less efficient, making it a powerful tool for various applications. Its core strength lies in its ability to rapidly advance through hard rock formations, providing a fast and cost-effective solution when dealing with consolidated materials.

Air rotary drilling is favored for its production of clean, dry cuttings, which are highly beneficial for accurate geological logging and environmental sampling. This method also minimizes the introduction of foreign substances into the ground, reducing the risk of contamination, a critical factor in sensitive environmental projects or water well installations.

Here are key reasons to choose the air rotary drilling method:

- Speed and Efficiency: This method achieves exceptionally high penetration rates, particularly when drilling through hard rock. This significantly accelerates project timelines, allowing for quicker completion and improved overall operational efficiency on site.

- Efficient Cuttings Removal: Compressed air effectively flushes rock cuttings from the borehole as soon as they are generated. This continuous and efficient removal keeps the drill bit working optimally, maintaining a clean hole and maximizing drilling progress without slowdowns.

- Environmental Benefits: Air rotary drilling uses compressed air instead of water or drilling muds. This drastically reduces water consumption, making it an environmentally friendly choice, especially in water-scarce regions, and eliminates the need for costly and complex fluid disposal.

- Clean Cuttings Production: The process generates dry, uncontaminated rock cuttings. This is crucial for accurate geological logging and environmental sampling, as it minimizes the potential for cross-contamination of aquifers or samples, ensuring reliable data for analysis.

- Suitability for Specific Formations: It is highly effective in competent, consolidated rock formations where other methods might be slow or prone to borehole instability. This makes it the preferred technique for foundations, geotechnical investigations, and mineral exploration in such challenging ground.

- Ideal for Arid Regions: Given its minimal water requirement, air rotary drilling is perfectly suited for projects in arid or remote regions where water availability is extremely limited. It allows for efficient drilling without significant logistical challenges related to water supply.

- Accurate Sample Collection: The method provides pristine, uncontaminated rock chip samples. These samples are vital for precise geological characterization, enabling engineers and geologists to gain an accurate understanding of subsurface conditions for various project designs.

- Immediate Groundwater Detection: The constant flow of air quickly brings any encountered groundwater to the surface. This allows for immediate and accurate identification of water-bearing zones, which is critical for water well drilling and environmental monitoring.

Air Rotary Drilling Advantages and Disadvantages

Air rotary drilling offers a balance of benefits and drawbacks, making it suitable for specific geological conditions and project requirements. Understanding these aspects is crucial for optimal application.

Advantages

Air rotary drilling boasts rapid penetration rates, especially in hard rock formations, significantly reducing drilling time. The use of compressed air instead of drilling mud results in cleaner boreholes and undisturbed samples, which is crucial for accurate geological and environmental assessments. This method also minimizes the need for water, making it environmentally friendlier and more suitable for arid regions. Furthermore, the absence of drilling fluids simplifies site cleanup and reduces disposal costs.

- Cost-Effective in Rock: Often more economical than other methods when drilling through competent rock.

- Dry Drilling: Ideal for areas with limited water availability or where water contamination is a concern.

- Reduced Formation Damage: Less invasive to the surrounding formation compared to mud rotary, preserving in-situ conditions.

Disadvantages

Despite its benefits, air rotary drilling has limitations. It is less effective in unconsolidated or unstable formations like loose sand or gravel, as the air pressure can cause borehole collapse. The method can also be noisy due to the powerful air compressor. Furthermore, if groundwater is encountered, the air pressure may not be sufficient to lift water and cuttings, hindering progress. There’s also a risk of air escaping into surrounding formations, which can be problematic in certain environmental contexts.

- Limited in Unconsolidated Formations: Not suitable for soft or fractured ground that collapses easily.

- Noise Pollution: The compressors and drilling operation can generate significant noise, impacting nearby communities.

- Potential for Lost Circulation: Air can escape into highly fractured or porous formations, reducing efficiency and potentially requiring alternative methods.

Air Flush Rotary Drilling

Recommended Air Flush Drill Bits

Air flush rotary drilling is a highly efficient method primarily used for geotechnical investigation and water well drilling. It utilizes compressed air to clear cuttings, offering advantages in specific ground conditions. This technique enhances drilling speed and sample recovery.

Mechanism

This drilling method employs a rotating drill bit to cut into the ground, while a high-pressure stream of compressed air is injected down the drill pipe. The air serves to cool the bit, stabilize the borehole, and, most importantly, flush rock cuttings and debris from the hole to the surface, allowing for continuous drilling operations without manual removal of cuttings.

Applications

Air flush rotary drilling is widely used in various fields due to its effectiveness in specific ground formations. Common applications include the drilling of water wells, environmental monitoring wells, and geotechnical boreholes for soil and rock sampling. It is particularly well-suited for unconsolidated or fractured rock formations where conventional mud drilling might be less efficient or problematic.

Advantages

The primary advantages of air flush rotary drilling include its speed and efficiency, especially in dry, stable formations. The use of air minimizes formation damage and provides clean, uncontaminated rock samples, which is crucial for accurate geological and geotechnical analysis. Furthermore, it eliminates the need for large volumes of drilling fluids, reducing logistical complexities and environmental impact on site.

Drilling With Air Flush

Drilling with air flush is an efficient method employing compressed air to remove cuttings from the borehole. This technique enhances drilling speed and maintains hole integrity, especially in specific geological conditions.

Process

In air flush drilling, a drill bit rotates and cuts into the formation, while a continuous stream of high-pressure compressed air is forced down through the drill pipe. This air travels to the drill bit, cools it, and then reverses direction, carrying the drilled cuttings up the annulus (the space between the drill pipe and the borehole wall) to the surface. This constant removal of cuttings ensures a clean borehole and allows for uninterrupted drilling.

Advantages

The use of air as a flushing medium offers several benefits over traditional mud drilling. It results in faster penetration rates, especially in hard and dry formations, as there’s less hydrostatic pressure on the borehole face. Air drilling also minimizes formation damage, provides cleaner and more accurate rock samples, and reduces the need for large volumes of drilling fluids, leading to lower disposal costs and environmental impact.

Suitable Conditions

Air flush drilling is particularly effective in dry, stable, and hard rock formations. It performs well in consolidated or fractured rock where water-based fluids might cause swelling or instability. It is also preferred in environments where water is scarce or where contamination from drilling fluids needs to be avoided, making it ideal for certain environmental and water well projects.

How to Choose Air Rotary Drilling Tools?

When choosing air rotary drilling tools, several critical factors must be considered to ensure efficiency, cost-effectiveness, and optimal performance for a specific project. The primary consideration revolves around matching the tools to the geological conditions of the drilling site, particularly the type and hardness of the rock and soil formations.

Geological Conditions:

- Rock Hardness & Abrasiveness: Different drill bits are designed for varying rock strengths, from soft formations where drag bits or augers might suffice, to very hard rock where down-the-hole (DTH) hammers or specialized roller cone bits are more effective.

- Formation Homogeneity: The consistency of the ground impacts tool selection; fractured or unconsolidated formations may require casing while drilling, influencing the type of rig and bit.

- Moisture Content: The presence of water or moisture can affect the efficiency of air flushing, potentially necessitating the addition of water mist or surfactants.

Beyond geological factors, the operational parameters of the drilling rig and the specific project goals significantly influence tool selection. The capabilities of the drill rig, including its torque, downward force, and air compression capacity, must align with the chosen tools to achieve the desired penetration rates and borehole quality.

Drilling Rig Capabilities & Project Goals:

- Rig Power & Torque: The rig must provide sufficient power and torque to effectively rotate the drill string and bit, especially when encountering challenging formations or using larger diameter tools.

- Desired Penetration Rate & Depth: Higher production rates in certain formations might necessitate more aggressive bit designs or a combination of drilling methods. The maximum drilling depth also plays a role in selecting appropriate drill pipe and bit types.

- Borehole Diameter & Stability: The required diameter of the borehole will dictate the size of the bit, and the need for borehole stability in loose formations might influence the choice of casing and dual rotary drilling techniques.

- Mobility of the Rig: The accessibility of the site may influence the choice between truck-mounted, crawler-mounted, or even crane-mounted rigs, which in turn can affect the type and size of drilling tools that can be effectively deployed.

Conclusion

Air rotary drilling truly unearths efficiencies in geotechnical exploration, offering unparalleled speed and adaptability across diverse ground conditions. Its minimal environmental impact and cost-effectiveness make it a preferred method for various projects.

By leveraging compressed air, this technique ensures cleaner boreholes and efficient material removal, leading to more accurate data collection. This precision is vital for sound engineering decisions in construction and environmental remediation.

For those seeking reliable and high-performance equipment, consider sourcing wholesale air flush drill bits from Sinodrills. Their specialized tools further enhance the efficacy and economic benefits of air rotary drilling in your next geotechnical endeavor.