Custom Casing Advancement System Manufacturer in China

We are a premier custom casing advancement system manufacturerin China, specializing in integrated and solitary ring bit systems. We engineer solutions tailored for your unique geotechnical needs, including deep piling, anchoring, and water well drilling in challenging overburden. Rely on us for robust, efficient, and precise drilling tools.

Sinodrills - Your Trusted Casing Advancement System Manufacturer from China

Sinodrills is a trusted Casing Advancement System Manufacturer from China, providing high-performance solutions for geotechnical and foundation drilling. We expertly engineer both eccentric (Odex) and concentric (Symmetrix) ring bit systems. Our custom tools are built for seamless casing installation through challenging overburden, ensuring maximum efficiency, hole stability, and reliable project completion worldwide.

Casing Advancement System Components

Pilot Bit: The central component connects to the Down-The-Hole (DTH) hammer on the drill string, providing the primary percussive and rotary force . It breaks the rock face and locks into the ring bit to advance the entire system.

Integrated Ring Bit: This component is a ring-shaped drilling tool with carbide buttons that is permanently welded to the casing shoe. It reams the hole slightly larger than the casing diameter, allowing the casing to follow immediately and stably.

Casing Shoe (or Casing Pipe): This is a heavy-duty steel component welded to the end of the steel casing pipe (pile). The integrated ring bit attaches here, transferring all the drilling energy to drive the casing string into the ground.

Casing Advancement System Benefits

Ensures Borehole Stability: The system simultaneously drills and advances the casing, providing immediate support to the hole walls. This prevents the borehole from collapsing in unstable, loose, or gravel formations.

Increases Drilling Safety: By casing the hole concurrently with drilling, the risk of blow-outs and ground disturbance is minimized. This is critical for operating safely in sensitive urban environments or near existing structures.

Achieves Straighter Piles: Concentric systems, which utilize the ring bit, drill with minimal deviation through all types of overburden and rock layers. This allows for highly accurate, on-grade foundation installation.

Penetrates Difficult Ground: The powerful DTH hammer technology combined with the full-face cutting structure allows easy penetration through hard rock, glacial till, and large boulders. This capability handles difficult, mixed soil conditions.

Reduces Overall Project Time: Simultaneous drilling and casing eliminates the need for multiple steps, which significantly streamlines the operation. This integrated, one-pass approach dramatically reduces on-site labor and time.

Casing Types

Permanent Casing

Permanent casing is a steel pipe left in the borehole to secure the integrity of the well or foundation. In water and geothermal wells, it acts as a sacrificial element to keep the hole open. For foundation work, it can serve as the primary bearing structure of the pile or provide corrosion protection.

Retrievable Casing

Retrievable casing systems are employed when the steel casing is only required temporarily during drilling to maintain an open borehole. They are a cost-effective solution for applications like piles and anchoring because the casing is retrieved and reused after the final structure (e.g., grout, anchor) is installed.

Casing Advancement System Models

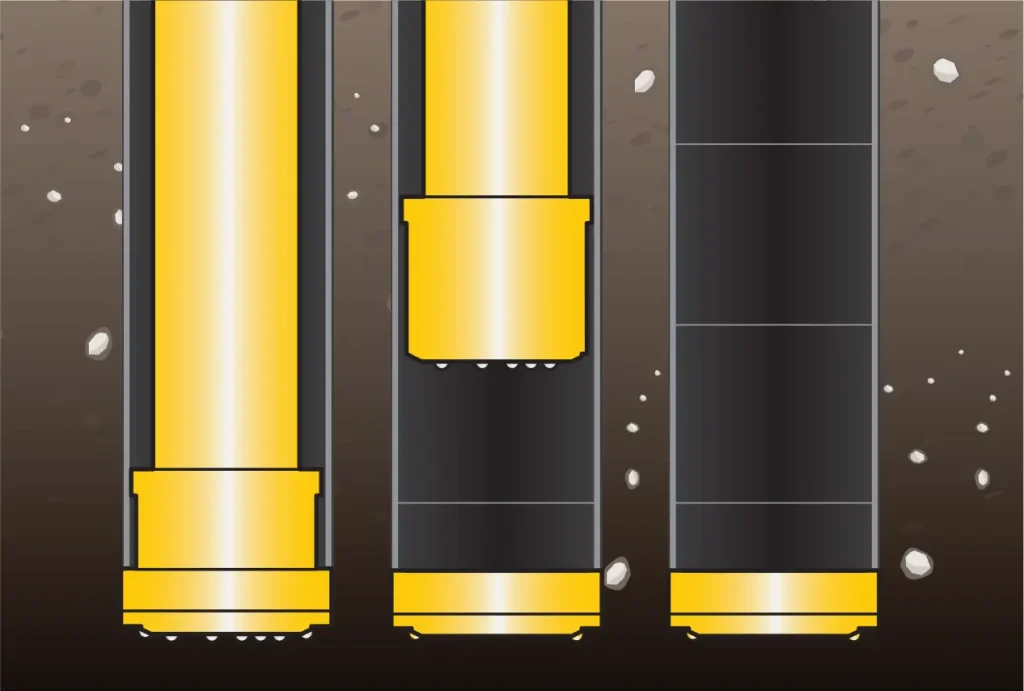

Eccentric Casing Systems (e.g., ODEX)

This system utilizes an eccentric reamer wing that swings out to cut a hole wider than the casing when rotating in one direction. The reamer wing retracts when rotation is reversed, allowing the drill bit assembly to be retrieved through the installed casing, making it highly reusable for shallower holes and smaller diameters.

Concentric Ring Bit Systems (e.g., Symmetrix)

A concentric system uses a symmetrical pilot bit that locks into a ring bit (or casing shoe) to drill a hole the exact size needed. This design is excellent for achieving maximum hole straightness and for drilling deeper, larger diameter holes through difficult formations, with the pilot bit often having a ‘drill-through’ feature.

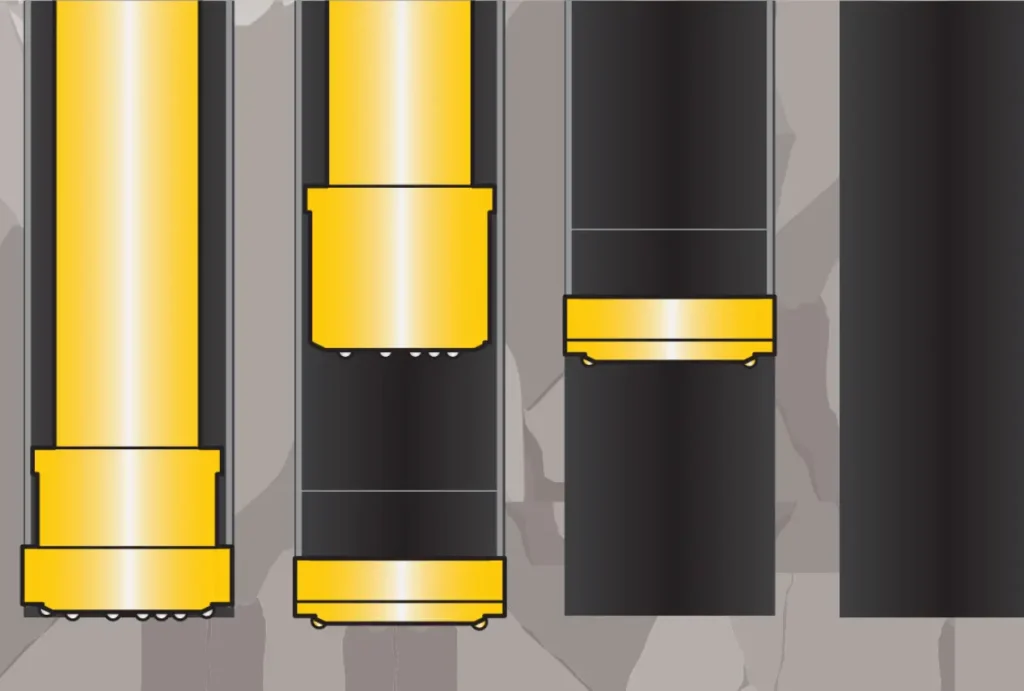

Advanced Concentric Systems (e.g., Elemex)

An advanced variation of the concentric design, Elemex is specifically engineered for sensitive ground conditions near existing structures. Its unique pilot bit design minimizes the risk of air and flushing medium escaping into the surrounding soil, which prevents ground disturbance and potential building settlement.

Retrievable Concentric Systems (e.g., WING KING)

Certain systems feature wings that extend to ream the hole and can retract without reverse rotation after reaching the target depth or bedrock. This mechanism allows the entire drilling assembly to be quickly pulled out of the casing for reuse, offering a highly productive, low-cost option for temporary casing applications.

Customize Your Desired Casing Advancement System

System Type and Application Focus

We customize the core system type, such as integrated, solitary, or retrievable designs, based on whether the casing is sacrificial or temporary. We consult on the optimal design for your end use, ensuring maximum efficiency for deep foundation piling, anchoring, or wall construction.

Diameter and Casing Compatibility

We precisely engineer the ring bit and casing shoe diameters to perfectly match your specific DTH hammer and steel pipe size. This ensures seamless synchronization during advancement, providing the precise fit required for the casing to follow immediately into the newly drilled hole without binding or wobble.

Carbide Button Configuration

We select the specialized carbide button shape, size, and grade (e.g., dome, ballistic) based on your anticipated geology, from abrasive sandstone to hard granite. This custom configuration is vital for maximizing penetration rate and increasing the service life of both the pilot and ring bits in harsh environments.

Flushing and Air Control Design

We optimize the flushing port design and air channels for efficient cuttings removal while minimizing air escape into the formation. This prevents dangerous over-drilling and ground disruption in sensitive areas like urban centers or clay formations. We can also integrate specialized flushing technologies.

what is casing advancement System?

A Casing Advancement System is an innovative drilling method used in geotechnical and foundation work to simultaneously drill a borehole and install the steel casing.

It typically employs a Down-The-Hole (DTH) hammer with a pilot bit and a ring bit to advance the casing through unstable or bouldery overburden. This process ensures immediate hole stability.

what is casing advancement System used for?

Casing Advancement Systems are predominantly used in civil engineering and geotechnical projects where drilling through challenging, unstable, or highly fractured formations is necessary.

Their core function is to ensure immediate hole integrity while penetrating difficult overburden, allowing a stable passage to the target depth or bedrock.

Foundation Piling and Anchoring These systems are essential for installing permanent end-bearing piles and tieback anchors in unstable soil. They ensure the structural casing reaches competent bedrock without collapsing, a crucial step for securing large buildings, bridges, and retaining walls in difficult ground.

Water and Geothermal Wells Casing advancement is vital for drilling well holes through loose sands, shales, and gravel, protecting the borehole from contamination and collapse. It securely cases the well’s upper section, ensuring long-term integrity and reliable water or geothermal fluid exchange.

Slope and Tunnel Stabilization The systems are used for installing pipe roofing ahead of tunnel faces or placing soil nail anchors for slope stabilization. This creates a pre-support structure in unconsolidated material, ensuring worker safety and preventing cave-ins during subsequent excavation.

Controlling Environmental Impact In sensitive urban areas, specialized Casing Advancement Systems (like Elemex) manage air and cuttings more precisely. This technique minimizes ground disturbance, preventing damage to nearby structures and adhering to strict environmental regulations.

why choose casing advancement Systems?

A Casing Advancement System (CAS) is the best choice for drilling through difficult, unstable, or bouldery ground because it eliminates hole collapse and streamlines the entire operation. By simultaneously drilling and installing the casing, these systems save considerable time and cost compared to traditional multi-step methods, delivering a higher quality, secure borehole every time.

Guaranteed Borehole Stability This system provides immediate support to the hole walls by installing the casing while drilling. This is critical in loose, unconsolidated formations like sand, gravel, and glacial till, completely eliminating the risk of a costly and dangerous cave-in or collapse.

Significant Time and Cost Savings The integrated single-pass process eliminates the non-productive time (NPT) associated with tripping out the drill string and running casing separately. Combining these two major operations into one drastically accelerates project completion and reduces overall operational costs.

Penetration of Difficult Formations CAS leverages the powerful percussive force of a Down-The-Hole (DTH) hammer, enabling easy penetration through challenging layers like hard rock, large boulders, and highly fractured zones. This ensures you can reach target depth reliably, even in mixed geology.

Enhanced Safety and Control Integrating the casing with the drill string provides greater control over the wellbore and minimizes exposure of personnel to hazards on the rig floor. By stabilizing the hole immediately, it also prevents issues like fluid loss or ground disruption in sensitive environments.

where to use casing advancement Systems?

Casing Advancement Systems (CAS) are primarily used in ground conditions that are unstable or prone to collapse, known as overburden, to ensure borehole integrity.

These simultaneous drilling and casing systems are essential in a multitude of civil engineering, environmental, and energy-related projects where a secure, cased hole is required to reach stable bedrock.

Foundation Piling and Micropiles In construction, CAS is used to install foundation elements like friction and end-bearing piles, particularly in urban areas or difficult ground. The casing can be left permanently as a structural part of the pile or used temporarily to keep the hole open until bearing elements are installed, ensuring reliable support.

Water and Geothermal Wells For well drilling, these systems case the unstable overburden sections to protect the water supply from contamination and prevent the hole from collapsing. This practice is common for both large municipal water wells and smaller-diameter geothermal heating system boreholes, minimizing environmental impact.

Ground Anchoring and Support CAS is vital for installing tieback anchors or ground anchors, which are used to stabilize slopes or retaining walls. The simultaneous drilling and casing provides the necessary temporary support in loose soil or fractured rock until the anchor itself can be securely placed and cemented.

Tunneling and Pipe Roofing In advanced tunneling operations, the pipe roofing technique utilizes CAS to install steel casings in an umbrella pattern ahead of the tunnel face. This pre-reinforces the ground, forming a secure arch that allows excavation to proceed safely and efficiently through weak strata.

Send Your Inquiry Now

All-in-one Casing Advancement System Solutions for Your Project

We provide complete casing advancement system Solutions for any geotechnical project. Choose from integrated (sacrificial) or retrievable (temporary) systems, including eccentric (Odex) and concentric (Symmetrix) designs. Our tools are customized for deep foundation piling, anchoring, and water well drilling through even the toughest overburden, ensuring optimal stability.