Custom Casing Shoe Manufacturer in China

Finding a custom casing shoe manufacturer in China requires careful consideration of quality, experience, and certifications. Leading manufacturers offer tailor-made solutions for diverse drilling needs, specializing in various materials and designs to ensure optimal performance and durability. Partner with a trusted Chinese company for reliable, high-quality products that meet your project’s specific requirements.

Sinodrills - Your Trusted Casing Shoe Manufacturer from China

Sinodrills is a premier manufacturer of casing shoes from China. We specialize in providing a wide range of custom solutions, including reamer shoes and coring casing shoes, to meet the specific demands of your drilling operations. Our casing shoes are engineered for superior performance and durability, ensuring successful casing runs in challenging wellbore conditions.

Casing Shoe in drilling

Guidance and Protection: The casing shoe’s rounded or tapered nose helps guide the casing string past ledges, washouts, and other obstacles in the wellbore, protecting the bottom of the casing from damage.

Cementing Operation: It serves as a base for cementing, creating a seal between the casing and the wellbore. The check valve within the shoe prevents the cement from U-tubing back into the casing.

Preventing Damage: By acting as a sacrificial component, the casing shoe prevents the end of the casing string from being damaged while navigating through tight spots and irregular formations.

Centralization: Some casing shoes have built-in centralizing fins or can be used with centralizers to help center the casing within the wellbore, ensuring a uniform cement sheath.

casing shoe in Concentric Drilling System

Conductor and Surface Casing: In the initial stages of a well, a casing shoe is used with conductor and surface casings to stabilize loose, unconsolidated formations near the surface, preventing them from collapsing into the hole.

Intermediate Casing: When drilling through unstable or high-pressure formations, casing shoes guide intermediate casings to the desired depth, ensuring the wellbore remains stable and ready for deeper drilling.

Production Casing: In the final phase of drilling, casing shoes guide the production casing to the target zone, protecting it as it navigates through formations to reach the hydrocarbon-bearing reservoir.

Horizontal and Directional Drilling: Specialized casing shoes, such as reamer or eccentric shoes, are crucial for horizontal and directional wells, as they help navigate tight turns and potential obstructions while reaming the borehole.

Overburden Drilling Systems: In geotechnical and mining applications, casing shoes are used to advance casing through loose overburden, gravel, or fractured rock, preventing material collapse and ensuring a stable hole.

Various Casing Shoe

concentric casing system casing shoe

We offer specialized concentric casing system casing shoes engineered for effective drilling in challenging formations. Our designs feature a concentric configuration that optimizes the drilling process, ensuring a stable and secure hole. These casing shoes are ideal for applications requiring continuous casing advancement through unconsolidated or difficult ground conditions, providing superior performance and reliability.

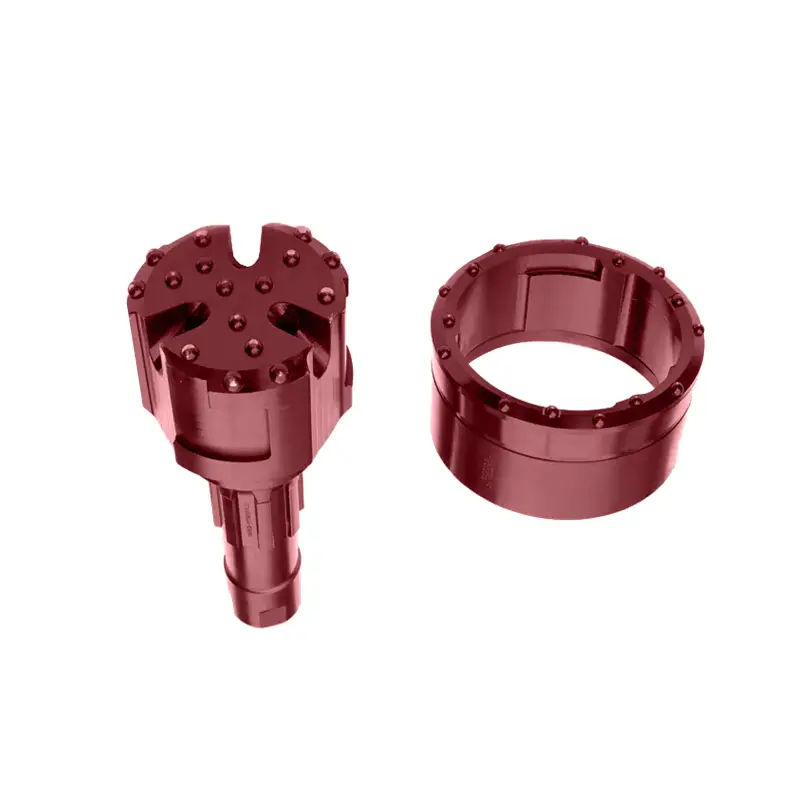

retrievable symmetrix casing system casing shoe

We offer a specialized retrievable symmetrix casing system casing shoe, designed for overburden drilling. This system allows for the simultaneous drilling and casing of the hole. Our casing shoe, along with the pilot and ring bit, creates an oversized borehole, allowing the entire drill string to be retrieved and reused for subsequent projects, minimizing waste and maximizing efficiency.

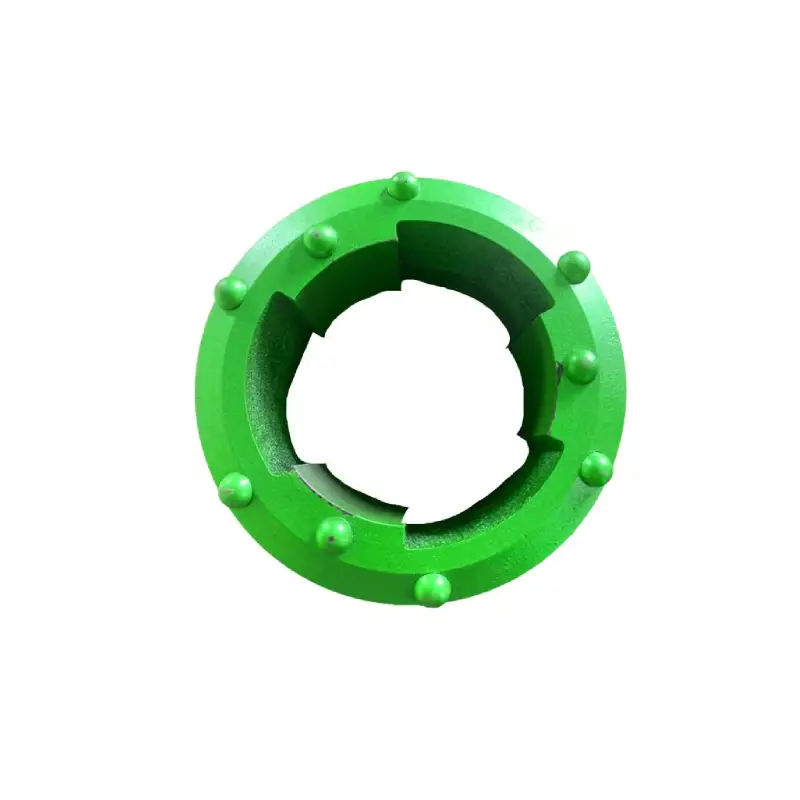

ring bit casing shoe

We provide advanced ring bit casing shoes, specifically designed for simultaneous drilling and casing in challenging overburden and hard rock formations. This system includes a robust casing shoe with integrated tungsten carbide buttons that reams the hole, allowing the casing to be advanced as drilling progresses. This method ensures a stable wellbore and saves valuable time.

Guide Casing Shoe

We offer the standard guide casing shoe, a simple yet effective tool designed to protect the casing string and guide it smoothly through the wellbore. Its bullet-like nose prevents the casing from catching on ledges or other obstacles, ensuring a successful run to the bottom of the hole.

Float Casing Shoe

We provide float casing shoes that incorporate a powerful backflow prevention valve. This essential feature allows cement slurry to be pumped out of the casing but stops it from U-tubing back in, ensuring a robust and stable cement column around the casing string.

Reamer Casing Shoe

Our casing reamer shoes are equipped with cutting elements that ream the wellbore as the casing is run in. This is particularly useful in tight holes or when navigating through formations with washouts, ensuring the casing can reach its full depth without getting stuck.

Coring Casing Shoe

We specialize in coring casing shoes, which are designed for applications where obtaining a continuous rock sample is critical. This specialized casing shoe allows for core retrieval while simultaneously advancing the casing, streamlining the drilling and sampling process for geological analysis.

Casing System Components

Ring Bit: This component initiates the drilling process, cutting an oversized hole to accommodate the casing. It ensures a smooth and precise start for the entire system, crucial for maintaining drilling accuracy.

Casing Shoe: Positioned at the bottom of the casing, the casing shoe protects the casing from damage during drilling and helps guide it into the drilled hole. Its robust design prevents premature wear and tear.

Retainer Ring: This ring securely holds the ring bit in place, preventing it from detaching during operation. It’s a critical safety feature, ensuring the integrity of the drilling assembly.

Casing: The primary structural component, the casing lines the drilled hole, preventing collapse and ingress of groundwater. It provides stability to the borehole, allowing for further operations to proceed safely.

Pilot Bit: This bit leads the drilling, creating a smaller pilot hole that the ring bit then enlarges. It’s essential for guiding the entire system and ensuring the correct trajectory of the borehole.

Customize Your Desired Casing Shoe

Material Selection

We can manufacture casing shoes from a variety of high-grade materials, including different grades of steel, to match your operational requirements. This allows us to optimize for durability and wear resistance in abrasive formations or to meet specific metallurgical specifications for corrosive environments, ensuring longevity and performance.

Connection Type

We can customize the casing shoe with various thread connections, including API, premium, and specific customer-requested threads. A proper connection ensures a secure and robust attachment to your casing string, preventing leaks and mechanical failure during installation and subsequent drilling or cementing operations.

Shoe Profile and Design

We offer customization of the shoe’s nose profile, from standard bullet-shaped to specialized eccentric or flat designs. This allows us to create a shoe that effectively navigates unique wellbore conditions, such as ledges or tight spots, while optimizing fluid flow and cement placement during the cementing process.

Special Features

We can add specialized features to the casing shoe to enhance its functionality. This includes integrating reaming elements for hard rock, installing specialized valves for backflow control, or incorporating centralizing fins. These additions provide a multi-functional tool that addresses complex drilling challenges in a single, reliable component.

what is casing shoe?

A casing shoe is a specialized device attached to the bottom of the casing string in a drilling operation. It is a critical component that serves multiple functions to ensure the success and integrity of the wellbore.

Primarily, its bull-nosed or rounded design helps guide the casing string through the wellbore, protecting it from damage as it navigates past ledges, washouts, and other potential obstructions.

Beyond guidance and protection, the casing shoe is integral to the cementing process, as it provides a path for cement to be pumped out of the casing and into the annulus, creating a stable seal between the casing and the wellbore wall. Some types, like the float shoe, also contain a check valve to prevent cement from flowing back into the casing.

what is casing shoe made of?

A casing shoe is typically a composite tool made from a combination of hard and drillable materials. The outer body of the casing shoe, which connects to the casing string, is generally made of high-grade steel to provide structural integrity and durability. The inner parts, including the nose or core, are made from materials that are easy to drill through later in the well’s life.

This allows for deepening the well after the casing is set.

Steel: The outer shell and threaded connections are made of steel to withstand the downhole stresses, including weight, rotation, and abrasion, while running the casing into the well.

Drillable Materials: The inner components are made from materials that can be easily drilled out by a standard drill bit. These often include cement, aluminum, or thermoplastics to ensure that drilling can continue to the next depth.

Tungsten Carbide and Diamonds: For specialized applications, like in reamer casing shoes or coring shoes, the tool may incorporate harder, more abrasive-resistant materials. This can include tungsten carbide inserts or even diamond cutting elements to aid in drilling through challenging formations.

what is casing shoe used for?

A casing shoe is an essential piece of equipment in drilling operations, primarily used to protect and guide the casing string as it is lowered into a wellbore. This is crucial for maintaining the integrity of the hole, especially in unstable formations where the wellbore might otherwise collapse.

It’s often the first component to touch the bottom of a new section of the hole.

Protecting the Casing: The casing shoe acts as a shield for the casing string, preventing the bottom end of the pipe from being damaged or bent as it scrapes against the wellbore wall or encounters hard formations.

Guiding the String: Its rounded or tapered nose helps guide the casing past obstacles like ledges and washouts, ensuring it reaches its target depth without getting stuck.

Facilitating Cementing: The shoe provides an exit for drilling fluids and a passage for the cement slurry that is pumped down the casing to create a seal in the annulus (the space between the casing and the wellbore).

Preventing Backflow: Certain types of casing shoes, known as float shoes, contain a check valve that prevents the cement slurry from flowing back into the casing after it has been placed, maintaining a proper cement column.

how to install casing shoe?

Installing a casing shoe is a critical step in preparing a wellbore for casing. The process is straightforward, ensuring the shoe is securely attached and functional before the entire casing string is lowered into the hole.

Proper installation guarantees the shoe performs its protective and guiding functions effectively.

Step 1: Preparing the Casing Joint

First, we inspect the bottom joint of the casing string to ensure the threads are clean and free of damage. We then apply thread compound, a specialized grease that lubricates the threads and helps create a pressure-tight seal, preventing leaks during operation and cementing.

Step 2: Threading the Casing Shoe

Next, the casing shoe is carefully threaded onto the bottom of the prepared casing joint. It’s crucial to ensure a proper, hand-tight fit before using a casing power tong or specialized tool to tighten the connection to the specified torque value fully.

Step 3: Verifying the Connection

Once the casing shoe is tightened, the connection is visually inspected to ensure there are no gaps between the shoe and the casing joint. We then verify that the torque applied meets the manufacturer’s and project’s specifications, which confirms a secure and robust mechanical connection capable of withstanding downhole forces.

Step 4: Lowering the String

With the casing shoe securely installed, the entire casing string, joint by joint, is lowered into the wellbore. The casing shoe, now at the very bottom, protects the string from damage and guides it past any obstacles or tight spots on the way to the final setting depth.

Send Your Inquiry Now

All-in-one Casing Shoe Solutions for Your Project

We provide all-in-one casing shoe solutions to meet the diverse needs of your drilling project. Our comprehensive range includes guide, float, reamer, and ring bit casing shoes, ensuring superior performance and durability in any wellbore condition. From standard designs to custom configurations, we deliver high-quality products that streamline your operations and maximize efficiency.