Choosing the right drill bit is crucial for achieving precise and clean holes in your projects. Concave and convex drill bits are two common types, each designed for specific tasks. Understanding their shapes, cutting edges, and applications can help you make the best choice for your drilling needs.

Concave drill bits feature an inward-curved design that allows smooth material removal, while convex drill bits have outward-curved edges for efficient cutting and durability. By knowing their differences, you can enhance your work efficiency, reduce wear on your tools, and ensure professional results in woodworking, metalworking, or other drilling applications.

What is a Concave Drill Bit?

A concave drill bit is designed with an inward-curved cutting surface that allows smooth material removal during drilling. It is widely used in rock drilling for creating precise holes while minimizing wear and enhancing drilling efficiency.

Features of Concave Drill Bits for Rock Drilling:

- Inward-Curved Cutting Edge: The concave shape helps concentrate force on the center, enabling precise penetration into hard rock surfaces while reducing bit slippage and ensuring consistent hole quality.

- Efficient Rock Material Removal: The curved design facilitates easy evacuation of rock fragments and debris from the hole, preventing clogging and maintaining smooth drilling performance over long periods.

- Enhanced Durability: Made from high-strength steel or tungsten carbide, concave drill bits resist abrasion and impact from hard rocks, ensuring longer service life and cost-effective drilling operations.

- Vibration Reduction: The concave geometry absorbs some of the drilling vibration, providing more stable drilling, reducing operator fatigue, and maintaining accuracy during prolonged rock drilling tasks.

- Versatile Applications: Ideal for mining, construction, and geological exploration, concave drill bits efficiently handle various rock types, including granite, basalt, and other hard surfaces, making them essential tools for professionals.

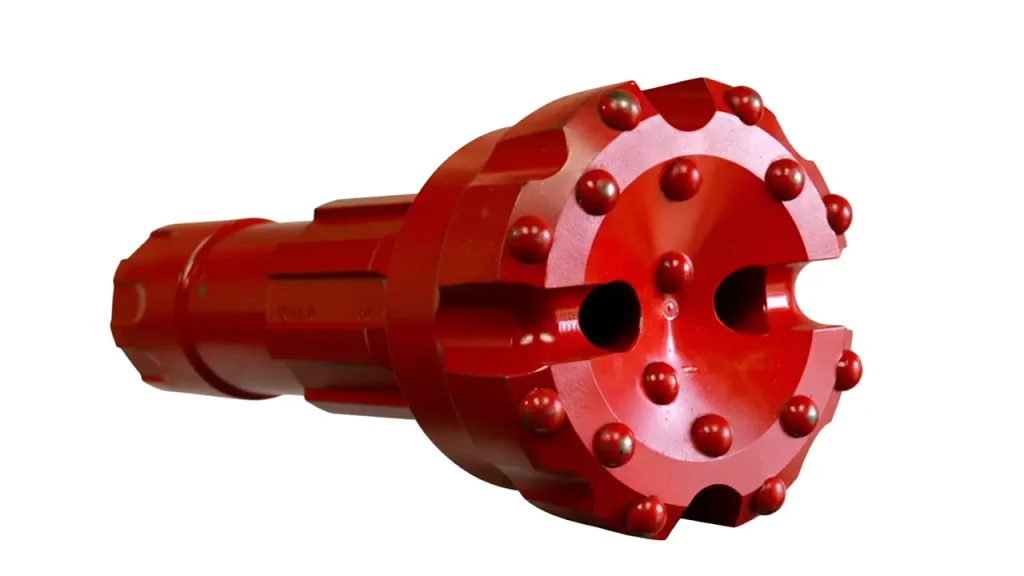

What is a Convex Drill Bit?

A convex drill bit has an outward-curved cutting edge designed to efficiently break and remove hard materials. It is widely used in rock drilling due to its strength and durability, ensuring smooth penetration through tough surfaces while maintaining stability and precision in demanding drilling projects.

Features of Convex Drill Bits for Rock Drilling:

- Outward-Curved Cutting Edge: The convex shape provides maximum contact with rock surfaces, allowing faster material removal while reducing wear and enhancing drilling efficiency in hard rock formations.

- High Strength and Durability: Made from hardened steel or carbide, convex drill bits resist deformation and chipping, ensuring long-lasting performance even under continuous heavy-duty rock drilling conditions.

- Efficient Penetration: The design allows the bit to cut deeper into hard rock with minimal force, maintaining a steady drilling speed while reducing the risk of bit sticking or jamming.

- Vibration Reduction: Convex bits help absorb and minimize vibration during rock drilling, providing smoother operation and preventing damage to both the drill bit and drilling equipment.

- Versatility for Tough Materials: These bits are ideal for various types of rock, including granite, basalt, and sandstone, offering consistent performance in mining, construction, and geological exploration projects.

Concave Drill Bit vs Convex

Understanding the differences between concave and convex drill bits helps improve drilling efficiency, material removal, and tool lifespan. Each type has unique designs suited for specific drilling tasks, especially in rock drilling and heavy-duty applications.

1. Shape Design

Concave drill bits have an inward-curved cutting edge that allows controlled material removal. This shape reduces stress on the bit and prevents chips from clogging, making it ideal for delicate or precision drilling tasks.

Convex drill bits feature an outward-curved edge that maximizes surface contact. This shape enhances penetration power, making convex bits better for tough, dense rock where high strength and durability are required for efficient drilling.

2. Material Removal Efficiency

Concave bits remove material slowly but steadily, providing smooth, precise cuts. The inward curvature ensures reduced resistance during drilling, which is useful for softer rock or situations requiring accuracy over speed.

Convex bits remove material aggressively due to the outward edge design. This allows for faster drilling in hard rock, breaking up dense surfaces quickly while maintaining the integrity of the bit over prolonged use.

3. Durability and Strength

Concave bits are less prone to cracking during light or moderate drilling, but their design limits heavy-duty rock drilling applications where stress concentration is high. They are best for controlled, precision-oriented tasks.

Convex bits offer higher durability and strength, resisting deformation and wear. Their robust design is suitable for heavy rock drilling and continuous operation, ensuring consistent performance under harsh conditions.

4. Vibration and Stability

Concave drill bits generate less vibration during use due to the inward curvature, providing smoother drilling experiences. This minimizes tool wear and prevents misalignment in delicate operations.

Convex drill bits may produce more vibration because of the aggressive cutting action, but their wider contact area ensures stable drilling in hard rock, reducing the likelihood of bit wandering or slipping.

5. Applications

Concave bits are ideal for precision drilling, softer rock, and situations where smooth, controlled cuts are required, such as geological sampling or intricate construction tasks.

Convex bits are preferred for heavy-duty rock drilling, mining, and construction projects requiring rapid penetration through dense or abrasive rock materials while maintaining long-lasting bit performance.

Here are some differences between concave drill bits and convex drill bits:

| Feature | Concave Drill Bit | Convex Drill Bit |

|---|---|---|

| Shape Design | Inward-curved edge | Outward-curved edge |

| Material Removal | Controlled, smooth | Aggressive, fast |

| Durability | Moderate, precision use | High, heavy-duty use |

| Vibration | Low | Moderate, stable in hard rock |

| Best Applications | Soft rock, precision drilling | Hard rock, mining, construction |

How to Choose Concave and Convex Drill Bits?

Selecting the right drill bit for rock drilling is essential for efficiency, durability, and precision. Concave and convex drill bits serve different purposes, and choosing the proper type depends on rock hardness, drilling speed, vibration tolerance, and project requirements to achieve optimal results.

Factors to Consider When Choosing Drill Bits:

- Rock Hardness: Assess the hardness of the rock you plan to drill. Concave bits perform better on softer rock, providing controlled cuts, while convex bits excel in hard, dense rock due to their aggressive cutting and durability.

- Drilling Speed: Determine whether fast penetration or precision is required. Convex bits allow rapid drilling through tough rock, whereas concave bits offer slower, smooth cutting suitable for delicate or controlled operations.

- Tool Durability: Consider how long the drill bit will last under continuous use. Convex bits are highly durable for extended rock drilling, while concave bits are better for moderate tasks requiring precision without heavy stress.

- Vibration Control: Evaluate your need for stability during drilling. Concave bits minimize vibration and provide smoother operation in delicate situations, whereas convex bits maintain stability despite aggressive cutting and high-resistance rock surfaces.

- Application Type: Identify your drilling goals, whether mining, geological sampling, or construction. Concave bits are suited for precise or soft rock tasks, while convex bits are ideal for heavy-duty, abrasive rock projects requiring high efficiency and strength.

Conclusion

In summary, concave and convex drill bits serve distinct purposes and excel in different scenarios. Concave bits are ideal for smooth, controlled cuts, whereas convex bits offer strength and durability for tougher materials. Choosing the right bit improves efficiency and ensures high-quality results in every drilling task.

By understanding the differences between these two types, you can optimize your projects, minimize tool damage, and achieve precise outcomes. Whether you are a professional or DIY enthusiast, selecting the appropriate drill bit enhances both performance and longevity of your tools.

For those looking to purchase high-quality drill bits, Sinodrills offers wholesale concave and convex drill bits with reliable performance. Get durable, precision-engineered bits from Sinodrills to meet all your drilling needs efficiently and cost-effectively.