Concentric drilling is a widely used method in geotechnical and construction projects, offering a practical solution for drilling through mixed or unstable ground. By using a pilot bit and reaming system, this technique creates stable, clean boreholes, making it ideal for foundation work, mining, and anchoring applications in challenging environments.

The efficiency of concentric drilling lies in its precision and reliability. Unlike traditional methods that may struggle in boulders or loose soil, concentric drilling provides consistent results with minimal deviation. This makes it a preferred choice for contractors and engineers looking for accuracy, speed, and reduced risks during demanding drilling operations.

What is Concentric Drilling?

Concentric drilling is a specialized drilling method that uses a pilot bit and an outer reamer to create straight, stable boreholes in difficult ground conditions. It is particularly effective for drilling through boulders, loose soil, and mixed formations, making it widely used in foundation construction, anchoring, mining, and geotechnical engineering projects.

How Does Concentric Drilling Work?

Concentric drilling works by creating a precise pilot hole using a central pilot bit, while reaming wings expand the hole to the desired size. This method ensures straight drilling paths, efficient penetration, and reliable hole quality across various ground conditions.

- Pilot Bit Function: The pilot bit initiates the drilling process by penetrating the rock and guiding the reaming wings. It ensures the borehole remains aligned, even in fractured or unstable formations, allowing smooth progress. This guidance reduces deviation, increasing accuracy in demanding construction and mining projects.

- Reaming Wings Expansion: Once the pilot bit establishes the center, reaming wings open to enlarge the hole. They cut through surrounding material effectively, producing a uniform diameter. The wings collapse when retrieved, simplifying recovery from the borehole. This expansion ensures efficiency and adaptability for different ground formations.

- Casing Advancement: Concentric drilling enables simultaneous advancement of casing along with the hole. The casing protects the drilled path from collapse and loose debris. This process is particularly valuable in unstable soil or mixed ground, ensuring hole stability, safety, and smooth project completion in challenging environments.

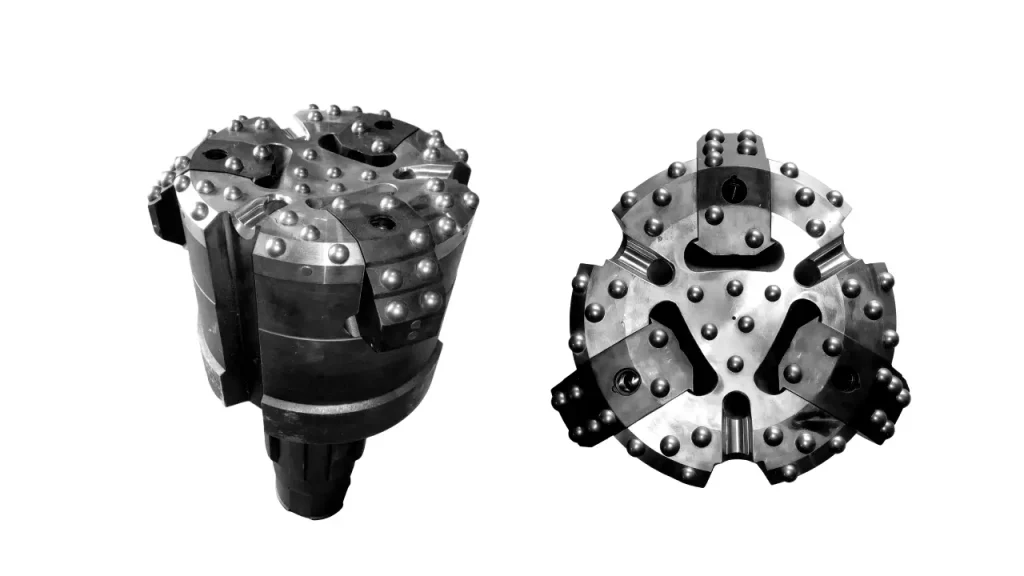

Concentric Drill Bits

Concentric drill bits are specialized tools designed for precision drilling in rock and other tough materials. They ensure straight holes, reduce deviation, and provide consistent results in demanding applications. Widely used in mining, tunneling, and construction, concentric drill bits improve productivity while maintaining accuracy in harsh drilling environments.

- Precision Drilling: Concentric drill bits are engineered to minimize hole deviation, ensuring a straight and accurate path through rock formations. This precision reduces rework, improves blasting efficiency, and guarantees reliable drilling performance across a wide range of challenging applications.

- Enhanced Efficiency: With a design that maximizes energy transfer, concentric drill bits allow for faster penetration rates. They reduce wear on drilling equipment, extend tool life, and ultimately lower operational costs, making them a cost-effective choice for heavy-duty drilling projects.

- Versatile Applications: These drill bits are used in mining, tunneling, foundation work, and geothermal drilling. Their robust design adapts to various ground conditions, providing dependable performance whether in soft or hard rock, ensuring flexibility for different industrial needs.

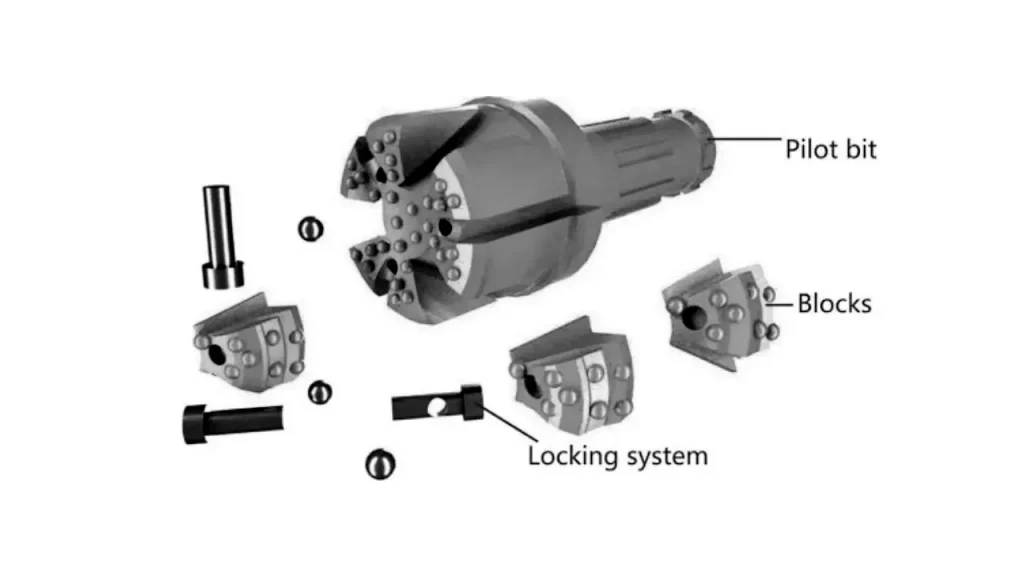

Concentric Drill Bit Components

Concentric drill bits consist of several key components that work together to achieve accurate and efficient drilling. Each part has a specific function, from cutting through rock to guiding the drill’s path. Understanding these components helps ensure optimal performance and extended tool life in challenging drilling environments.

- Pilot Bit: The pilot bit leads the drilling process, ensuring the hole stays aligned and accurate. It initiates penetration into the rock and guides the reamer for concentric cutting, reducing deviation and enabling smoother drilling progress in both soft and hard formations.

- Reamer: The reamer enlarges the hole created by the pilot bit, cutting the rock with precision. Its design ensures that the hole maintains a consistent diameter, improving blasting efficiency and allowing proper placement of casing or support structures in demanding applications.

- Ring Bit: The ring bit provides structural strength around the cutting zone, protecting the reamer and pilot bit from excessive wear. It also ensures the drilled hole maintains stability, especially in fractured or loose ground conditions, making it essential for durability and long service life.

- Shank Adapter: The shank adapter connects the drill string to the concentric drill bit, transferring energy from the hammer to the cutting components. It plays a vital role in efficient power delivery, reducing energy loss, and ensuring smooth, continuous drilling performance in various rock formations.

How to Choose Concentric Drill Bits?

Choosing the right concentric drill bits depends on ground conditions, drilling goals, and equipment compatibility. Selecting suitable bits ensures higher efficiency, accuracy, and cost savings in projects. Careful evaluation of bit design, durability, and material compatibility helps achieve stable drilling operations and long-term performance.

- Assess Ground Conditions: The ground type greatly affects the bit selection. Hard rock requires durable carbide or tungsten tips, while softer soils may need lighter designs. Evaluating the geology ensures better penetration and reduces tool wear. Matching the bit to conditions enhances drilling precision and extends operational efficiency.

- Check Equipment Compatibility: Concentric drill bits must match drilling rigs and casing systems. Compatibility ensures smooth operation, reduces downtime, and avoids damage to expensive equipment. Selecting a bit designed for your rig specifications helps maximize efficiency, ensures safe drilling, and prevents unnecessary technical problems during extended use.

- Focus on Durability: Stronger materials extend the lifespan of concentric drill bits. Bits manufactured with advanced alloys and reinforced cutting structures withstand wear in demanding projects. Durability lowers replacement costs, minimizes downtime, and supports consistent performance. A robust bit investment ultimately improves productivity across mining, construction, and foundation drilling applications.

- Evaluate Hole Diameter Needs: Projects demand specific hole diameters for casings, anchors, or utilities. Choosing the right size ensures alignment with casing advancement and overall design requirements. Accurate sizing prevents misalignment, avoids material waste, and guarantees stability. Proper diameter selection is crucial for safe and cost-effective drilling operations.

Conclusion

Concentric drilling continues to prove its value in modern construction and geotechnical industries. Its ability to maintain borehole stability while handling difficult ground conditions sets it apart from conventional drilling methods. With increased efficiency and reduced downtime, it ensures projects stay on schedule and within budget.

Choosing the right concentric drill bits is key to achieving the best performance. High-quality tools not only enhance drilling precision but also extend equipment life, ensuring greater productivity. Reliable suppliers provide durable solutions that stand up to the rigors of heavy-duty operations across various applications.

For contractors, miners, and engineers seeking dependable tools, wholesale concentric drill bits from Sinodrills are the smart choice. With a strong reputation for quality and innovation, Sinodrills delivers equipment designed to optimize performance. Partnering with them ensures you gain access to reliable drilling solutions that support project success and long-term value.