Drilling through hard rock is one of the most demanding tasks in mineral exploration and construction, pushing drill bits to their absolute limits. This blog delves into the fascinating world of drill bit technology, exploring the innovations that are fundamentally changing how we approach these challenging formations. Get ready to uncover the secrets to superior performance!

From advanced materials to groundbreaking designs, modern drill bit technology is engineered to maximize penetration rates, extend operational life, and significantly reduce overall drilling costs. We will examine the key factors that contribute to optimizing performance, ensuring your drilling operations are more efficient and productive even in the toughest rock.

What is Drill Bit Technology

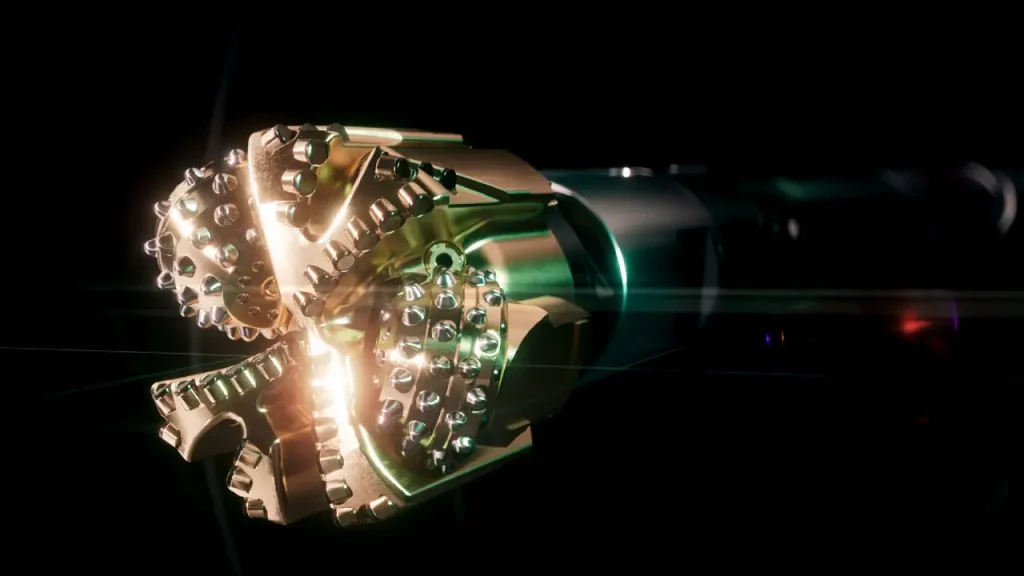

Drill bit technology encompasses the science and engineering behind the design, manufacturing, and application of the cutting tools used to bore holes into various materials, particularly rock in the context of mineral exploration. It involves continuous innovation in materials (like tungsten carbide and synthetic diamonds), geometric configurations (such as point angles, flutes, and cutter arrangements), and surface coatings.

The goal of this technology is to optimize the drill bit’s ability to penetrate rock efficiently, maximize its lifespan, enhance the quality of the retrieved samples, and ultimately reduce the overall cost and time of drilling operations in diverse and challenging geological environments.

Advancements in Drill Bit Technology

Advancements in drill bit technology continually push the boundaries of what is possible in drilling, making operations more efficient, cost-effective, and environmentally friendly. These innovations are critical for industries ranging from mineral exploration to oil and gas, where penetrating challenging geological formations is a daily reality.

Improved Materials and Coatings

Modern drill bits now incorporate incredibly durable materials like enhanced tungsten carbide composites and synthetic diamond structures, far surpassing traditional steel. These materials are often coupled with advanced coatings such as titanium nitride or specialized ceramics. This combination dramatically increases wear resistance and thermal stability, allowing bits to maintain their cutting edge longer and operate effectively in higher temperatures generated by friction, significantly extending their operational life in abrasive rock formations.

Optimized Bit Geometries and Designs

Engineers are continuously refining the physical shape and cutting elements of drill bits to improve their interaction with rock. This includes innovative cutter placement patterns, revised face profiles, and enhanced junk slot designs that more efficiently evacuate cuttings. These geometric optimizations reduce energy consumption, minimize bit balling in sticky formations, and improve overall penetration rates, leading to faster drilling progress and reduced downtime.

Integration of Smart Technology and Sensors

The advent of smart drilling tools has brought embedded sensors directly into drill bits. These sensors can monitor real-time drilling parameters such as temperature, vibration, torque, and weight on bit. This data is transmitted to the surface, allowing drillers to make immediate adjustments to optimize performance, prevent premature bit failure, and even provide valuable information about the rock being drilled, moving towards more autonomous and data-driven drilling operations.

Enhanced Manufacturing Processes

Advanced manufacturing techniques, including additive manufacturing (3D printing) and precision machining, are enabling the creation of drill bits with previously impossible complex geometries and internal cooling channels. These processes allow for greater customization and consistency in bit production, leading to bits that are not only more effective but also more reliable, with fewer structural weaknesses.

Focus on Environmental Impact

New drill bit technologies are also being developed with an eye towards reducing environmental impact. This includes designing bits that produce less fine cuttings, consume less energy, and are made from more recyclable materials. The goal is to achieve more efficient drilling with a smaller carbon footprint and reduced waste, aligning with global sustainability efforts in the mining and energy sectors.

Qualified Drill Bits with Advanced Technology

Recommended Drill Bits

Qualified drill bits with advanced technology represent the pinnacle of drilling tool engineering, offering superior performance, extended lifespan, and enhanced data acquisition in mineral exploration. These drill bits are distinguished by their meticulous design, use of cutting-edge materials, and integration of innovative features that collectively overcome the inherent challenges of drilling through diverse and often abrasive rock formations.

Investing in such advanced bits translates directly into significant operational efficiencies and more accurate geological insights, ultimately optimizing the entire exploration process.

- Superior Material Composition: Qualified drill bits utilize high-grade materials like enhanced tungsten carbide inserts, thermally stable polycrystalline diamond compact (PDC) cutters, and natural or synthetic diamonds, ensuring exceptional hardness, wear resistance, and thermal stability for extended operational life in tough rock.

- Optimized Cutting Structures and Geometry: Advanced design software and manufacturing precision lead to optimized cutter placement, blade configurations, and flushing systems. This ensures maximum rock-cutting efficiency, improved chip evacuation, and reduced friction, which collectively increase penetration rates and minimize bit balling.

- Enhanced Durability and Longevity: Beyond just materials, the structural integrity of qualified drill bits is fortified through advanced bonding techniques, robust bearing systems (for roller cone bits), and specialized wear protection on critical areas like gauge pads. This extends the drill bit’s life, reducing the need for frequent bit changes and associated downtime.

- Integrated Monitoring and Smart Features: Some cutting-edge bits incorporate sensors that provide real-time data on drilling parameters such as temperature, vibration, and torque. This “smart” technology allows drillers to optimize drilling parameters on the fly, proactively manage bit wear, and even gather valuable downhole information for geological analysis.

- Application-Specific Specialization: Qualified advanced bits are often tailored for specific rock types or drilling challenges (e.g., highly abrasive formations, interbedded layers, or unstable ground). This specialization ensures the bit’s design precisely matches the requirements of the formation, maximizing performance and sample integrity for the given conditions.

Conclusion

Throughout this exploration of drill bit technology, we’ve seen how continuous innovation is crucial for tackling the challenges of hard rock drilling. The advancements in materials, design, and manufacturing processes are not just incremental improvements; they are fundamentally reshaping the efficiency, cost-effectiveness, and safety of drilling operations across various industries.

For projects demanding robust ground support, especially in challenging environments, consider the benefits of wholesale self-drilling anchors for slope stabilization from Sinodrills. These anchors offer a reliable and efficient solution for preventing erosion and ensuring long-term stability in areas prone to movement. Their integrated drilling and grouting capabilities streamline installation, making them ideal for rapid deployment.

Sinodrills provides a comprehensive range of high-quality self-drilling anchors that are engineered to meet the stringent demands of slope stabilization. By choosing our durable and expertly designed anchoring systems, you can significantly enhance the safety and longevity of your infrastructure projects, ensuring peace of mind for years to come.