Understanding drill pipe displacement is fundamental to effective drilling fluid management, a cornerstone of safe and efficient wellbore operations. When drill pipe is run into or pulled out of the well, it displaces a significant volume of drilling fluid, directly impacting annular pressures and the overall hydraulic system. Accurate calculation of this displacement is critical for maintaining well control and optimizing drilling parameters.

Ignoring the precise volume displaced by the drill string can lead to serious issues, from costly fluid losses and inefficient hole cleaning to dangerous wellbore instability and kicks.

This blog post will delve into the essential methods for calculating drill pipe displacement, providing you with the knowledge to ensure accurate fluid management and enhance operational safety and efficiency in your drilling projects.

What is Displacement in Drilling?

In drilling, “displacement” refers to the volume of fluid that a tubular (like drill pipe, casing, or tubing) or downhole tool occupies within the wellbore. When these items are lowered into the well, they physically push, or “displace,” an equal volume of the existing drilling fluid out of the annulus and up to the surface.

Conversely, when tubulars are pulled out of the hole, a void is created, and fluid must be pumped into the well from the surface to fill that void. Accurate knowledge of this displaced volume is critical for maintaining wellbore hydrostatic pressure, managing fluid inventories, preventing kicks (unwanted influx of formation fluids), and ensuring precise execution of operations like cementing.

Drill Pipe Displacement Formula

Calculating drill pipe displacement is essential for managing drilling fluid volumes, maintaining proper hydrostatic pressure, and preventing well control issues. The basic principle is to determine the volume of steel in the pipe. This is typically expressed in barrels per foot (bbl/ft) for convenience in drilling operations.

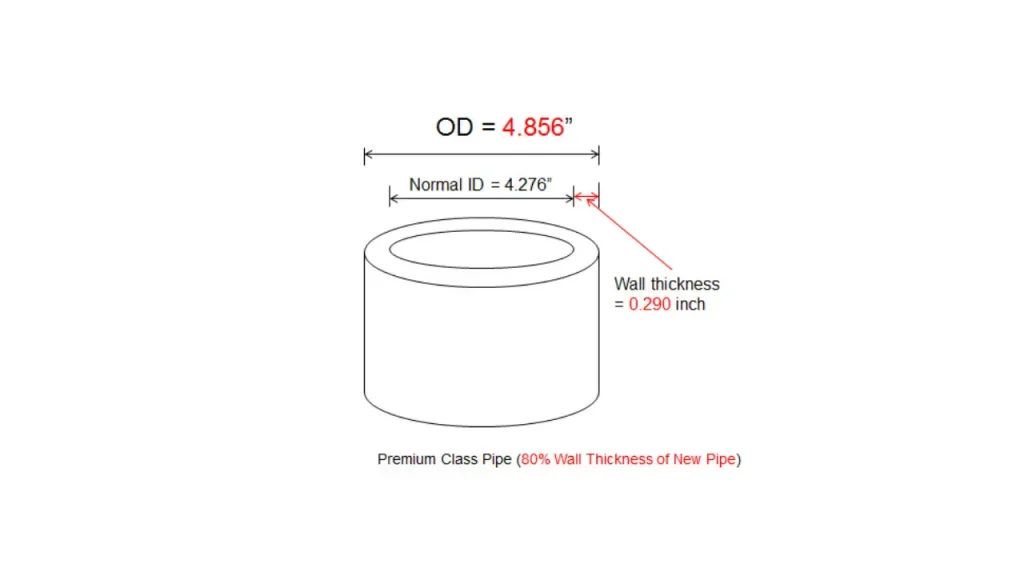

While simple pipe volume can be calculated using basic cylindrical volume formulas, drill pipe specifically includes tool joints, which are larger in diameter and must be accounted for to achieve accurate displacement.

For plain pipe (like casing or tubing without tool joints), the displacement can be calculated using the following formula, which represents the volume of the steel between the outer and inner diameters:

- OD in: Outer Diameter of the pipe in inches

- ID in: Inner Diameter of the pipe in inches

- 1029.4: Conversion constant to get barrels per foot (derived from 1 barrel = 5.6146 cubic feet, and 1 foot = 12 inches)

However, for drill pipe, this formula is not entirely accurate because it doesn’t account for the additional volume displaced by the larger tool joints. Drill pipe specification sheets provided by manufacturers (like Sinodrills) will list the actual, more accurate displacement values per foot, which integrate the average displacement contribution of the tool joints over the length of the pipe.

When these specific values are unavailable, a common rule of thumb for standard drill pipe sizes (e.g., 4.5″ and 5″) is to add approximately 0.001 bbl/ft to the plain pipe displacement to compensate for the tool joints. This ensures a more precise calculation for fluid management, crucial for maintaining wellbore stability and preventing costly drilling incidents.

Drill Pipe Capacity and Displacement

Quote Us Now

Drill pipes play a crucial role in drilling operations, affecting both fluid flow and overall efficiency. Understanding their capacity and displacement helps optimize drilling performance, reduce downtime, and ensure safe operations. Correct pipe selection directly impacts pressure management, cuttings removal, and drilling speed, making capacity and displacement key factors in any project.

- Internal Capacity: The internal volume of a drill pipe determines how much drilling fluid it can carry. Adequate capacity ensures efficient circulation, prevents fluid bottlenecks, and allows cuttings to be transported to the surface effectively. Proper sizing improves hydraulic performance and overall drilling efficiency.

- Displacement Rate: Displacement refers to the volume of drilling fluid pushed through the pipe per unit time. Monitoring displacement helps maintain consistent pressure, prevents formation damage, and enhances wellbore cleaning. Optimizing displacement ensures smooth drilling operations and minimizes risks of stuck pipe or other complications.

- Flow Efficiency: Drill pipe capacity affects flow efficiency within the drill string. Proper flow prevents sediment build-up, reduces friction losses, and allows smooth mud circulation. This efficiency translates to faster drilling rates and less wear on equipment, saving both time and operational costs.

- Pressure Management: Knowing displacement and capacity helps manage downhole pressure. Correct pipe sizing balances pump output with borehole requirements, reduces surge and swab effects, and protects formations. Effective pressure control is critical for maintaining well integrity and avoiding costly drilling issues.

- Optimized Performance: Matching drill pipe capacity with project requirements maximizes drilling performance. Efficient displacement and internal volume lead to better cuttings transport, reduced equipment stress, and improved overall drilling safety. Careful selection ensures smooth operations across various formations and well depths.

Drill Pipe Displacement Chart

Quote Us Now

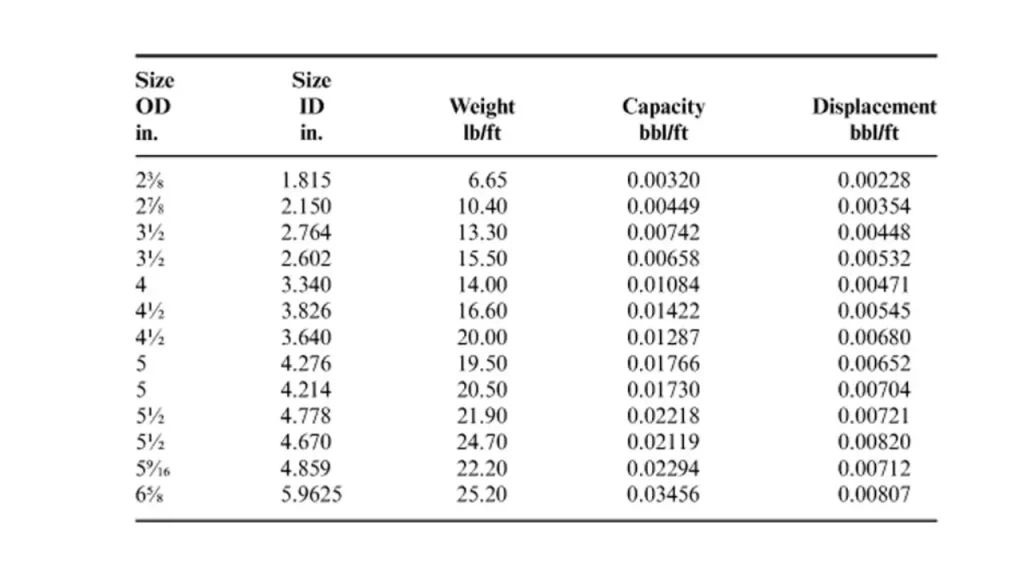

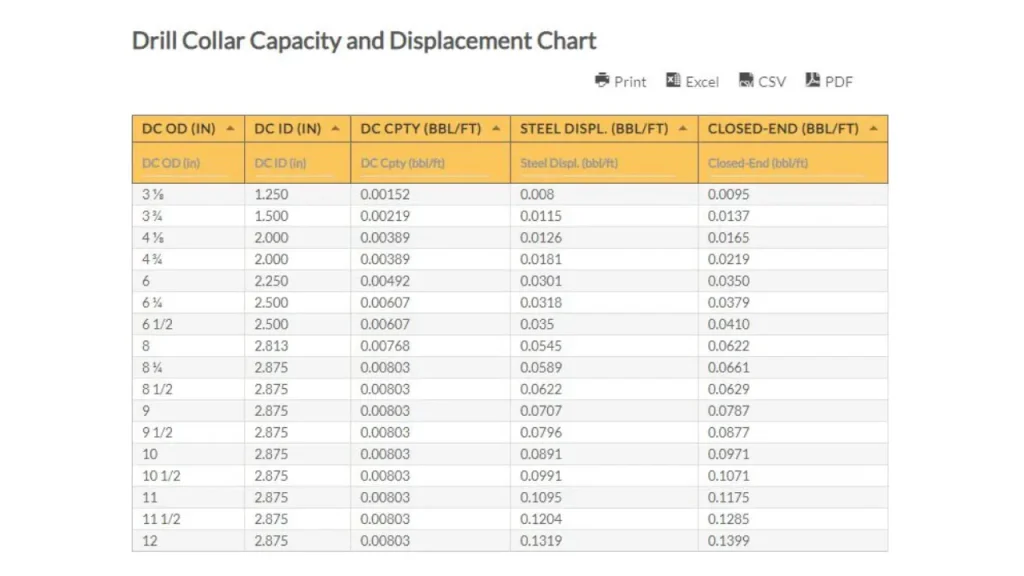

A drill pipe displacement chart provides a quick and convenient reference for the average volume of fluid displaced per unit length (e.g., barrels per foot or liters per meter) for various common sizes and weights of drill pipe. These charts are compiled by manufacturers and industry organizations, incorporating the complexities of tool joint dimensions and upset configurations to offer practical, averaged values.

Using a displacement chart streamlines calculations for fluid management, allowing drilling personnel to rapidly estimate changes in drilling fluid volume during tripping operations, thereby aiding in maintaining constant wellbore fill and preventing kicks or lost circulation. While precise calculations depend on specific pipe dimensions and wear, these charts offer reliable working figures for most field applications.

Here’s a simplified example of what a drill pipe displacement chart might look like (values are approximate and can vary by manufacturer and pipe condition):

| Nominal OD (in) | Nominal Weight (lb/ft) | Typical Displacement (bbl/ft) |

| 2-3/8 | 4.85 | 0.0028 |

| 2-7/8 | 6.85 | 0.0035 |

| 3-1/2 | 13.30 | 0.0070 |

| 4 | 14.00 | 0.0105 |

| 4-1/2 | 16.60 | 0.0140 |

| 5 | 19.50 | 0.0175 |

| 5-1/2 | 21.90 | 0.0210 |

| 6-5/8 | 25.20 | 0.0340 |

Note: For precise figures, always refer to the specific drill pipe specification sheet provided by your manufacturer, such as those from Sinodrills, as actual displacement can vary based on wall thickness, upset type, and tool joint dimensions.

How Do You Calculate the Volume of a Drill Pipe?

Calculating the volume of a drill pipe, often referred to as its “displacement,” is crucial for accurate fluid management in drilling operations. Essentially, we are determining the volume of the steel itself. The fundamental approach involves calculating the volume of a cylinder, then subtracting the internal volume to find the volume of the material.

However, for drill pipe, a key consideration is the presence of tool joints, which are thicker sections at the ends, adding to the overall displaced volume. Therefore, a simple calculation of the pipe body’s volume won’t be entirely accurate; real-world displacement values account for these larger tool joints.

For practical purposes, drill pipe volume (displacement) is commonly expressed in barrels per foot (bbl/ft). While manufacturers provide specific displacement charts for their products (like those from Sinodrills) that account for tool joints, a theoretical calculation for the pipe body can be performed using its outer diameter (OD) and inner diameter (ID).

The general formula for the volume of a pipe body, representing the volume of the steel, is based on the difference between the volume of the outer cylinder and the inner cylinder. This value is then converted to the desired units.

Drill Pipe Displacement Calculator

Important Note:

This calculator determines the theoretical displacement of the plain pipe body. For highly accurate drill pipe displacement, especially when considering tool joints and specific upset configurations, always refer to the manufacturer’s drill pipe specification sheet (e.g., from Sinodrills).

Conclusion

Accurate drill pipe displacement calculations are not just a theoretical exercise; they are a vital practice for real-world drilling success. By precisely accounting for the volume of fluid displaced by the drill string, operators can maintain optimal wellbore conditions, prevent costly incidents, and ensure the safety of personnel and equipment. This foundational understanding underpins efficient fluid programs, critical for every drilling project.

Mastering these calculations empowers drilling teams to make informed decisions regarding mud weights, pump rates, and trip speeds, ultimately leading to smoother operations and reduced non-productive time. It’s an essential skill that directly contributes to the economic and operational success of any drilling venture, from conventional to highly complex wells.

For all your drilling needs, including wholesale drill pipes essential for accurate displacement management, look no further than Sinodrills. We provide reliable solutions that support your commitment to precision and efficiency in drilling operations.