Friction welding is the cornerstone of manufacturing high-quality drill pipes, seamlessly joining the tough tool joint to the pipe body. This solid-state bonding technique uses controlled rotation and pressure to generate intense heat, fusing the metals without melting them, ensuring a powerful and extremely reliable connection critical for drilling integrity.

This complex process is not just about the weld; it includes essential steps like stress relief (annealing), flash removal, non-destructive testing, and hardbanding. These stages ensure the finished drill pipe can withstand the tremendous fatigue, torque, and abrasion encountered in the most demanding deep-well drilling operations globally.

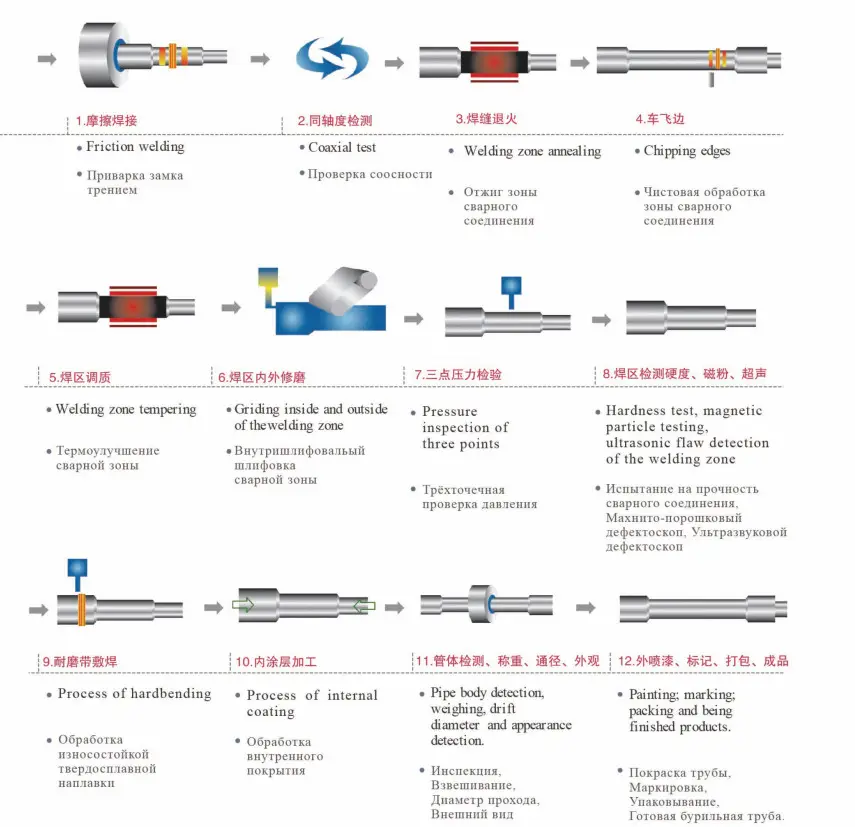

Drill Pipe Friction Welding Process

Drill pipe friction welding is a crucial manufacturing process that joins two separate steel sections—the tool joint and the pipe body—into a single, high-strength component. This method uses rotational speed and axial force to generate intense heat, fusing the metals together without melting them.

The entire process involves a series of critical thermal and mechanical treatments, followed by comprehensive quality inspections, to ensure the resulting weld and final product meet the stringent requirements for downhole drilling operations, guaranteeing both durability and reliability.

Step 1. Friction welding

The process begins by rotating one component, usually the tool joint, at high speed against a stationary part, the pipe body. Applying an axial force creates frictional heat at the interface. This heat softens the metal, allowing the two pieces to forge together, forming a solid-state weld that is extremely strong.

The key to a successful friction weld is controlling the rotation speed, friction pressure, and forge force. This precise control ensures that impurities are extruded from the joint, creating a clean, high-integrity bond that is essential for surviving the harsh stresses of drilling.

Step 2. Coaxial test

After welding, the pipe undergoes a coaxial test to measure the alignment of the pipe and the tool joint. This inspection is critical because any significant runout or eccentricity can lead to excessive vibration during drilling, causing premature wear and failure.

The coaxiality check uses precision instruments to verify that the central axes of the two joined components are perfectly straight and continuous. Maintaining this geometric accuracy is vital for smooth rotation and transmitting torque effectively down the drill string.

Step 3. Welding zone annealing

The welding zone annealing is a heat treatment applied immediately after the friction welding to relieve internal stresses built up during the rapid heating and cooling. This tempering process restores the material’s toughness, preventing the weld zone from becoming brittle.

Annealing involves heating the weld area to a specific temperature and then slowly cooling it under controlled conditions. This thermal cycle promotes a uniform microstructure across the joint, maximizing the fatigue life and overall strength of the final drill pipe.

Step 4. Chipping edges

Chipping the edges, or flash removal, is a mechanical process where the excess metal—known as flash—that was squeezed out during the forging stage is cut away. This flash contains impurities and oxidized material expelled from the weld.

This step involves both internal and external removal to create a smooth contour. A clean, smooth surface is essential not only to ensure the proper flow of drilling fluids but also to reduce stress concentrations that could otherwise initiate cracks.

Step 5. Welding zone tempering

Welding zone tempering, also known as post-weld heat treatment, refines the microstructure further than the initial annealing. This step is tailored to achieve the optimal hardness and tensile strength required for the specified grade of the drill pipe.

By precisely controlling the temperature and time, this process enhances the mechanical properties of the entire weld zone. The goal is to match the strength and toughness of the weld to that of the original pipe body, ensuring uniform performance.

Step 6. Griding inside and outside of the welding zone

Grinding is the final stage of surface preparation, which involves meticulously smoothing the internal and external surfaces of the welding zone. This operation removes any remaining flash or surface imperfections left by the chipping process.

A smooth surface dramatically improves the product’s resistance to corrosion and wear, especially in the high-flow internal bore. This finishing ensures minimal friction against drilling fluid, preventing turbulence and pressure loss during circulation.

Step 7. Pressure inspection of three points

This is a high-precision dimensional quality control check focusing on the pipe’s concentricity and straightness at three specific points. It is a final verification to ensure the entire pipe body and joint assembly remain geometrically true after all heat treatments.

The test identifies any subtle bends or deviations from the central axis that could affect drill string rotation. Strict adherence to straightness tolerances is crucial for high-speed drilling and preventing whirl or lateral vibrations downhole.

Step 8. Hardness test, magnetic particle testing, ultrasonic flaw detection of the welding zone

This is a multi-faceted non-destructive testing (NDT) sequence to guarantee the weld’s integrity. Tests check for correct hardness, surface-breaking defects (magnetic particle), and internal flaws (ultrasonic) within the crucial weld area.

These inspections ensure the weld is free of critical imperfections like cracks, voids, or inclusions that would compromise the structural safety of the drill pipe under extreme drilling loads. This rigorous testing confirms the weld quality meets industry safety standards.

Step 9. Process of hardbanding

Hardbanding is the application of a layer of wear-resistant metal alloy circumferentially around the tool joint. This extra layer is crucial for protecting the outer diameter of the joint from abrasive wear against the wellbore rock.

This process greatly extends the life of the drill pipe and protects the casing from excessive wear caused by the rotating pipe. The high-performance hardband material is carefully selected and applied to maximize abrasion resistance and operational longevity.

Step 10. Process of internal coating

Internal coating involves applying a protective polymer or epoxy liner to the interior surface of the pipe body and tool joint. This thin layer is essential for preventing corrosion caused by drilling fluids and corrosive downhole environments.

The coating acts as a barrier against chemical attack, which can lead to premature pipe failure and washing out. Maintaining this internal integrity is vital for preserving wall thickness and ensuring the long-term flow efficiency of the drilling fluid.

Step 11. Pipe body detection, weighing, drift diameter and appearance detection

The final comprehensive check involves verifying the overall pipe specifications. This includes measuring the drift diameter to ensure passage of downhole tools, confirming weight and dimensions, and visually inspecting the pipe’s external appearance.

These checks ensure the pipe conforms to all necessary dimensional and structural standards before being deployed. The rigorous final inspection guarantees that the pipe will be fully compatible with all rig equipment and operational procedures.

Step 12. Painting, marking, packing and being finished products

The last step is the preparation of the drill pipe for shipment and field use. This includes painting for corrosion protection, marking with critical specifications (like grade and size), and securing the threads for transport.

Proper packaging, often involving thread protectors, prevents damage to the critical connection ends during handling and logistics. The final marking provides all the necessary traceability and specification data for the drilling crew in the field.

Conclusion

The drill pipe friction welding process is a stringent manufacturing lifecycle, guaranteeing the fusion of the tool joint and pipe body into a robust, high-performance unit. Every stage, from initial welding to final NDT, is critical for achieving a connection capable of resisting extreme downhole forces. This comprehensive approach is what dictates the reliability and safety of the entire drill string.

By meticulously controlling the heat treatment and geometry, the finished drill pipe achieves superior fatigue life, excellent coaxial alignment, and maximum durability against abrasion. Investing in pipes manufactured through this exacting process minimizes costly downhole failures and maximizes your operational efficiency, translating directly to a lower cost per foot drilled.

For your next project, ensure quality and consistency by choosing to get wholesale drill pipes from Sinodrills. Our products adhere to the highest international standards, featuring meticulously friction-welded joints, advanced hardbanding, and protective coatings, providing the reliable foundation your most challenging drilling campaigns demand.