Drill rod sizes are a critical factor in the success of any drilling operation, influencing everything from drilling depth and core recovery to operational efficiency and cost. Understanding the various industry-standard dimensions, such as AQ, BQ, NQ, HQ, and PQ, is essential for selecting the right tools for your specific geological conditions and project requirements.

Choosing the appropriate drill rod size can significantly impact the stability of your boreholes, the quality of your core samples, and the overall productivity of your drilling program. This blog post will demystify these common drill rod designations, helping you make informed decisions for optimal drilling performance.

What are Drill Rods?

Recommended Drill Rods

Drill rods are robust, hollow cylindrical tubes, typically made from premium alloy steel, that are integral to various drilling applications, particularly in mining, geological exploration, and water well drilling. These segments are threaded together to form a “drill string” that connects the drilling rig at the surface to the drill bit at the bottom of the borehole.

Their primary functions include transmitting rotational torque and impact force from the rig to the drill bit, facilitating the removal of drill cuttings, and delivering drilling fluids (like water or mud) to cool and lubricate the bit. Due to the extreme stresses and abrasive conditions they endure, drill rods are engineered for exceptional strength, durability, and resistance to wear and deformation.

Drill Rod Sizes

The selection of appropriate drill rod sizes is paramount for efficient and effective drilling operations. These rods, forming the drill string, must match the desired core diameter, drilling depth, and geological conditions.

Understanding the various classifications, from standard DCDMA sizes to larger and specialized options, is key to optimizing your drilling project.

AQ Drill Rod

The AQ drill rod is one of the smallest and lightest in the “Q” series, typically used for shallow-to-medium depth drilling where smaller core samples are sufficient. Its compact size makes it ideal for highly maneuverable rigs and applications requiring minimal disturbance to the ground.

AQ rods are often employed in initial exploration, geotechnical investigations, and environmental sampling where quick penetration and detailed stratigraphic data from smaller cores are prioritized.

BQ Drill Rod

Slightly larger than the AQ, the BQ drill rod offers a good balance between maneuverability and increased core size. It is a popular choice for a wide range of exploration and geotechnical projects, providing larger core samples than AQ while still maintaining relatively high drilling speeds.

BQ rods are versatile, suitable for various ground conditions, and are frequently used when a more substantial core is needed for detailed analysis without moving to the heavier NQ system.

NQ Drill Rod

The NQ drill rod is perhaps the most commonly used size in mineral exploration and geotechnical drilling worldwide. It strikes an excellent balance between core diameter, drilling depth capability, and overall operational efficiency. NQ rods allow for the recovery of larger, more representative core samples, which are crucial for accurate geological logging and resource estimation. Their robust design also enables deeper drilling in challenging formations.

HQ Drill Rod

Moving up in size, the HQ drill rod provides an even larger core diameter, making it invaluable for projects requiring substantial sample volumes or when drilling through highly fractured or unstable ground. The larger annulus around the core barrel allows for better flushing and stabilization, reducing the risk of core wash-out and improving recovery rates. HQ rods are often employed in advanced exploration, mine development, and large-scale geotechnical investigations.

PQ Drill Rod

The PQ drill rod is the largest standard size in the “Q” series, designed for applications demanding the largest possible core samples. This size is typically used for bulk sampling, large-diameter geotechnical boreholes, or when drilling through very difficult ground conditions that necessitate maximum stability and flushing capacity. While slower to drill due to their weight and larger diameter, PQ rods provide unparalleled sample volume and hole integrity.

Larger and Specialized Drill Rod Sizes

Beyond the common AQ to PQ series, various larger and specialized drill rod sizes exist to meet unique drilling demands. These can include larger diameter conventional drill pipes used in oil and gas or water well drilling, or custom-fabricated rods for specific geotechnical or environmental projects.

These larger diameter drill rods are designed for heavy-duty applications, allowing for even greater depths, larger boreholes, or specialized tooling, often requiring more powerful drilling rigs and equipment.

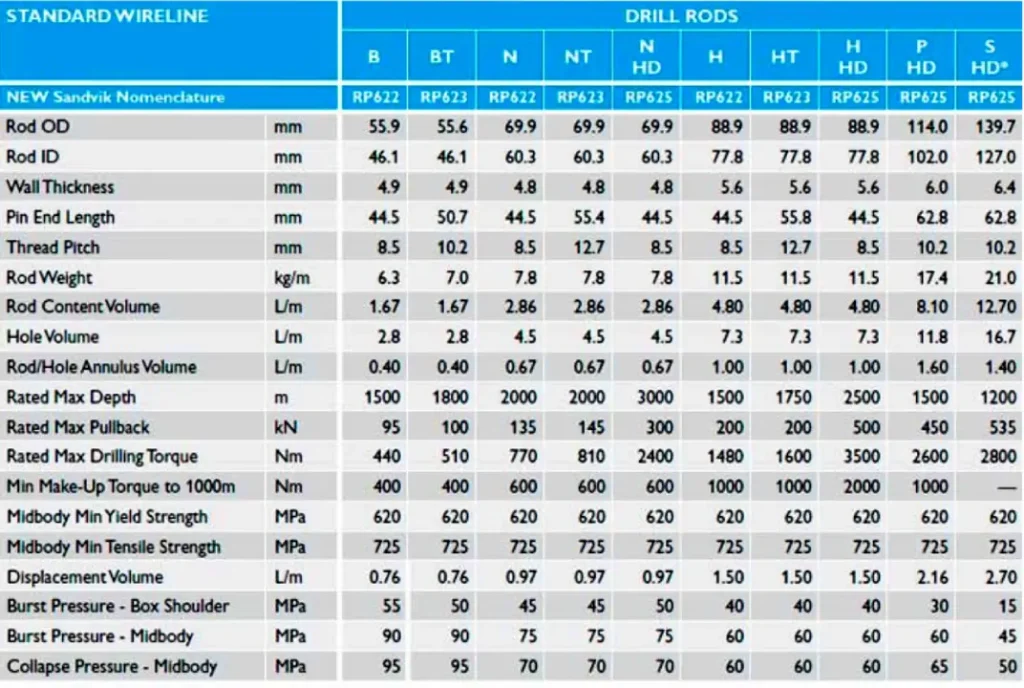

Drill Rod Size Chart

| Drill Rod Size | Approximate Outer Diameter (OD) | Approximate Inner Diameter (ID) | Common Core Diameter |

| AQ | 46 mm (1.81 in) | 36 mm (1.42 in) | 27 mm (1.06 in) |

| BQ | 56 mm (2.20 in) | 42 mm (1.65 in) | 36.5 mm (1.44 in) |

| NQ | 70 mm (2.76 in) | 54 mm (2.13 in) | 47.6 mm (1.87 in) |

| HQ | 89 mm (3.50 in) | 75 mm (2.95 in) | 63.5 mm (2.50 in) |

| PQ | 114 mm (4.49 in) | 92 mm (3.62 in) | 85 mm (3.35 in) |

| S-Series | Varies, typically larger than PQ | Varies | Varies |

| Conventional | Varies widely | Varies widely | N/A (often no core) |

Note: Dimensions are approximate and may vary slightly based on manufacturer and specific standards (e.g., DCDMA, ISO).

Choosing The Right Drill Rod Size

When we select a rod size, we balance the need for geological information against the speed and cost of the project.

- Sample Quality: Larger sizes like HQ and PQ provide more rock material. This is crucial if we need to see the structure of the rock or perform detailed lab tests.

- Drilling Depth: Smaller rods like NQ are lighter. This allows us to drill much deeper holes before the weight of the drill string exceeds the capacity of the rig.

- Ground Stability: If we are drilling in unstable or “bad” ground, larger rods provide more stability and better fluid circulation, which helps prevent the hole from collapsing.

Standard Wall Vs Triple Tube

You might also see these followed by a number, such as NQ3 or HQ3. This refers to a triple-tube system. We use these to protect very fragile core samples by adding an extra inner split tube, which prevents the rock from washing away or breaking during recovery.

Drill Rod Diameters

Drill rod diameters vary widely, from tiny sizes for precision work to large diameters for heavy-duty industrial drilling. The choice depends on the specific application, considering factors like rock type, desired hole size, and the capacity of the drilling rig. The right diameter ensures optimal performance and a longer tool life.

- Small Diameters: Used for precision applications such as geological sampling, geotechnical investigations, and creating custom tools and dies.

- Medium Diameters: Common in construction, civil engineering, and medium-scale mining for applications like foundation drilling and rock anchoring.

- Large Diameters: Employed for large-scale mining, quarrying, and oil and gas drilling, where powerful rigs are used to create deep and wide boreholes.

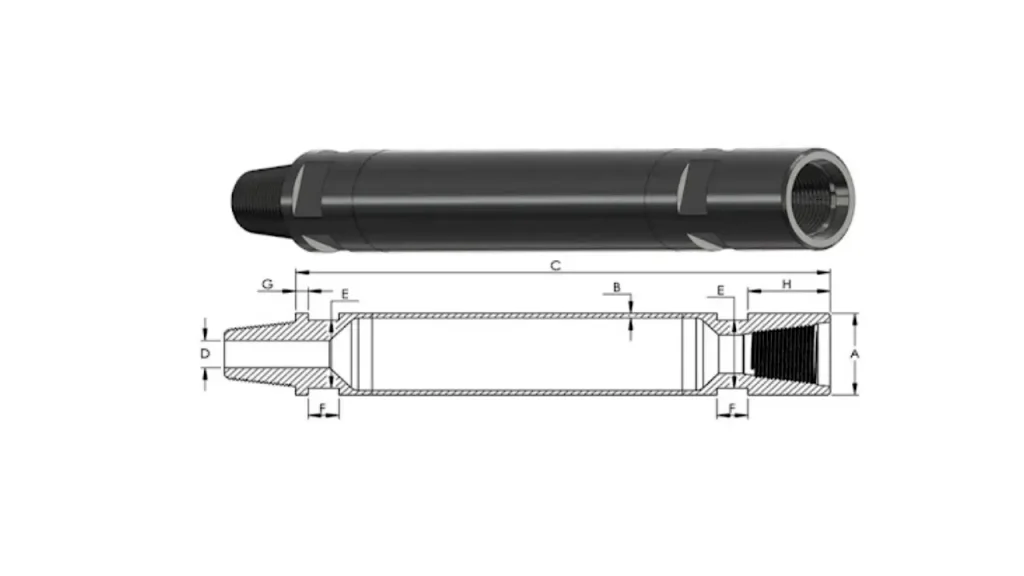

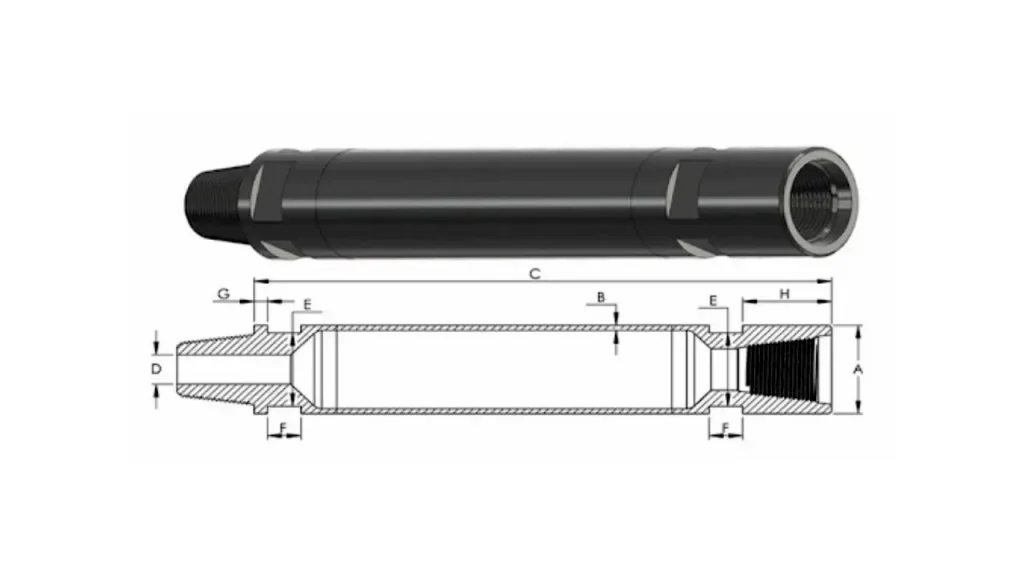

How to Measure Drill Rod Sizes?

Accurately measuring drill rod sizes is essential for compatibility with drill bits, core barrels, and the overall drilling system. This process typically involves precise measurements of both the rod’s external and internal dimensions.

Step 1: Measure Outer Diameter (OD)

The outer diameter is the measurement across the external surface of the drill rod’s main body. Use a caliper or micrometer to ensure precision, taking multiple readings along the rod’s length and rotating it slightly to account for any minor irregularities or wear. This measurement determines the clearance within the borehole.

Maintaining consistency in your measurements is crucial for accurate classification. Take readings at several points along a rod section, avoiding the threaded connections, and average them to get a reliable outer diameter value. This ensures the rod fits correctly into the hole and casing.

Step 2: Measure Inner Diameter (ID)

The inner diameter refers to the measurement across the hollow core of the drill rod. This dimension is particularly important for core drilling, as it dictates the maximum size of the core sample that can be retrieved through the rod. Use an internal caliper or a specialized bore gauge for precise measurement.

Accurate inner diameter measurement ensures proper fluid flow for flushing cuttings and cooling the bit, as well as allowing the core barrel to freely pass through. Verify the measurement at both ends and the middle of the rod to ensure uniform internal dimensions for efficient operation.

How to Choose Suitable Drill Rod Sizes?

Choosing the suitable drill rod size is crucial for optimizing drilling efficiency and core quality. This decision impacts everything from sample recovery to operational costs. Selecting the correct rod ensures your project proceeds smoothly, delivering the necessary geological data while maximizing equipment lifespan and minimizing downtime. It’s a strategic choice, not just a technical one.

- Target Core Size: The primary determinant; larger core samples (e.g., HQ or PQ) provide more geological information, while smaller cores (AQ, BQ) allow for faster penetration. Match the drill rod’s inner diameter to the desired core diameter for optimal sample recovery and minimal core damage.

- Drilling Depth: Deeper holes typically require stronger, often larger diameter rods (NQ, HQ) to withstand increased torque, weight, and bending forces, ensuring stability and preventing buckling over long drill strings. Smaller rods might be too flexible for significant depths.

- Ground Conditions: Formations that are highly fractured, unconsolidated, or abrasive benefit from larger rods (HQ, PQ) which offer greater rigidity, better flushing capabilities to remove cuttings, and reduce the risk of rod breakage or hole collapse in challenging geology.

- Drilling Rig Capacity: Ensure your drilling rig has sufficient power, torque, and hoisting capacity to handle the weight and rotational resistance of the chosen drill rod size, especially for larger diameters and deeper holes to avoid overloading the equipment.

- Logistical Considerations: Larger and heavier rods (HQ, PQ) require more effort, larger equipment for handling, and increased transportation costs. Assess the site accessibility and available infrastructure to ensure practical and cost-effective operations, balancing technical needs with practical constraints.

Conclusion

Mastering the nuances of drill rod sizes like AQ, BQ, NQ, HQ, and PQ is fundamental for achieving peak drilling performance and cost-efficiency. Each size offers unique advantages, and selecting the correct one ensures borehole stability, superior core recovery, and extended tool life. Armed with this knowledge, you’re better equipped to tackle diverse drilling challenges.

Remember, the right drill rod isn’t just about size; it’s about quality and precision. High-quality rods minimize downtime and maximize productivity. For reliable and robust drilling solutions tailored to your specific needs, consider partnering with a trusted manufacturer.

When you’re ready to elevate your drilling operations, remember Sinodrills. We offer a comprehensive range of wholesale customized drill rods designed to meet the highest industry standards. Contact us today to discuss your project and discover how our expertise can benefit you.