Choosing the right drilling method is crucial for the success and efficiency of any project. From construction and mining to oil and gas exploration, selecting the appropriate technique can significantly impact timelines, costs, and overall results. This blog post will guide you through the essential factors to consider when deciding on a drilling method.

We’ll explore various drilling techniques, highlighting their unique characteristics, applications, and limitations. By understanding the nuances of each method, you can make an informed decision tailored to your specific project requirements, ensuring optimal performance and minimizing potential challenges.

What is Drilling

Drilling is a fundamental material removal process that involves creating a cylindrical hole in a solid material by using a rotating cutting tool called a drill bit.

This bit is advanced into the workpiece, and its cutting edges shear away material in the form of chips. Drilling is a versatile technique used across numerous industries for various purposes, from creating simple fastener holes to complex internal passageways.

Drilling Method

Exploring the diverse world of drilling unveils a fascinating array of techniques, each meticulously developed to tackle specific materials and project demands. From the robust power of impacting hammers to the delicate precision of focused energy beams, the choice of drilling method is paramount for efficiency and success.

This overview delves into nine distinct drilling approaches, highlighting their unique mechanisms, key advantages, and typical applications across various industries. Understanding these methods is the first step towards selecting the optimal technique for your specific drilling needs.

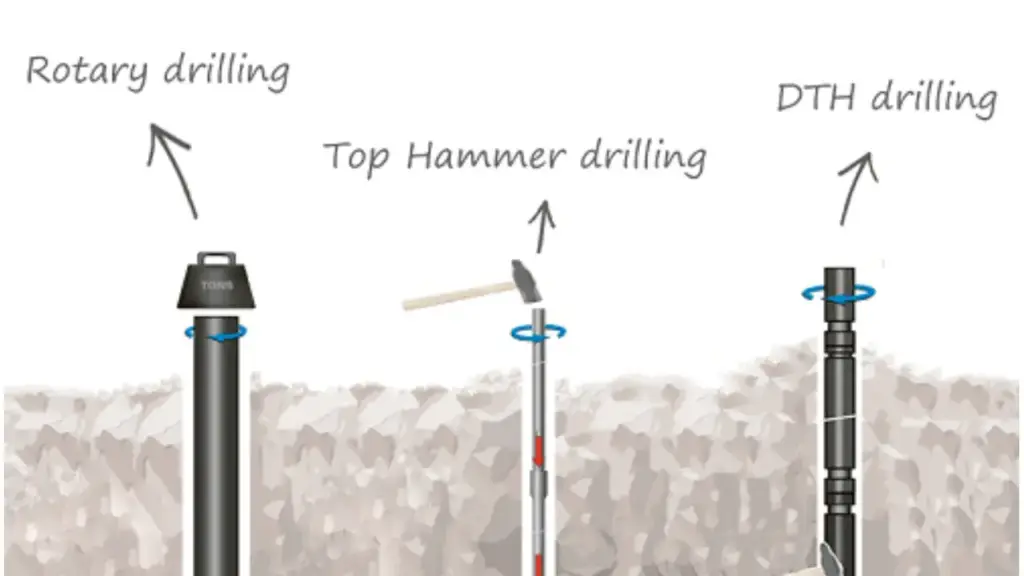

DTH Drilling

Down-the-Hole (DTH) drilling is a pneumatic powered rock or ground drilling method where the percussive hammer is located directly behind the drill bit. Compressed air is used to activate the hammer, which simultaneously rotates and impacts the ground. This impact action, combined with rotation, effectively fractures hard rock and other resistant materials. The compressed air also serves to flush the loosened drill cuttings upwards and out of the borehole.

Benefits: DTH drilling is highly effective for drilling in hard to very hard rock formations and for penetrating large boulders. The direct impact behind the bit ensures efficient energy transfer, leading to high penetration rates in tough conditions. It also tends to produce straighter boreholes compared to some other methods.

Uses: This method is widely used in mining for drilling blast holes, in quarrying, and in construction for drilling through hard rock for foundations, anchors, and other applications. It’s also employed in water well drilling in consolidated formations.

Rotary Drilling

Rotary drilling is a common technique that uses a rotating drill bit to create a borehole. The drill bit, attached to a drill string or spindle, is forced into the material while rotating, causing the cutting edges to shear away material. Different variations exist, including air rotary and mud rotary, which use compressed air or drilling mud respectively to remove cuttings and stabilize the borehole.

Benefits: Rotary drilling is versatile and can be used in a wide range of materials, from soft soils to hard rock, depending on the bit type and drilling parameters. It offers relatively fast drilling speeds and good control over the borehole diameter and depth. It’s also adaptable to various drilling rig types.

Uses: This method is employed in geotechnical and environmental site investigations for collecting soil and rock samples, in oil and gas exploration, in water well drilling, and in construction for various applications like foundation work and installing ground anchors.

Percussion Drilling

Percussion drilling combines rotary motion with a hammering action to fracture and remove material. The drill bit is repeatedly struck while it rotates, delivering impact force to the drilling surface. This method is particularly effective for drilling into hard and brittle materials like rock and concrete, where the hammering action helps to overcome the material’s resistance to cutting.

Benefits: Percussion drilling excels in penetrating hard materials quickly and efficiently. The hammering action pulverizes the material, allowing for faster drilling rates compared to rotary drilling alone in such applications. It is a robust method suitable for tough conditions.

Uses: This technique is essential in construction for drilling holes for anchors, dowels, and blasting. It is also widely used in mining and quarrying to create boreholes for exploration and extraction.

Diamond Drilling

Diamond drilling utilizes a drill bit embedded with industrial diamonds to cut through extremely hard materials. The diamond particles, being one of the hardest known substances, abrade the material as the bit rotates. This method typically requires a coolant to reduce heat and flush away debris, ensuring efficient cutting and prolonging bit life.

Benefits: Diamond drilling can cut through very hard and abrasive materials with high precision and produce smooth, clean holes. It generates less heat compared to some other methods when properly cooled and can achieve tight tolerances.

Uses: This method is crucial in geological exploration for core sampling, in the semiconductor industry for creating precise holes in silicon wafers, and in the construction industry for cutting through reinforced concrete and tile.

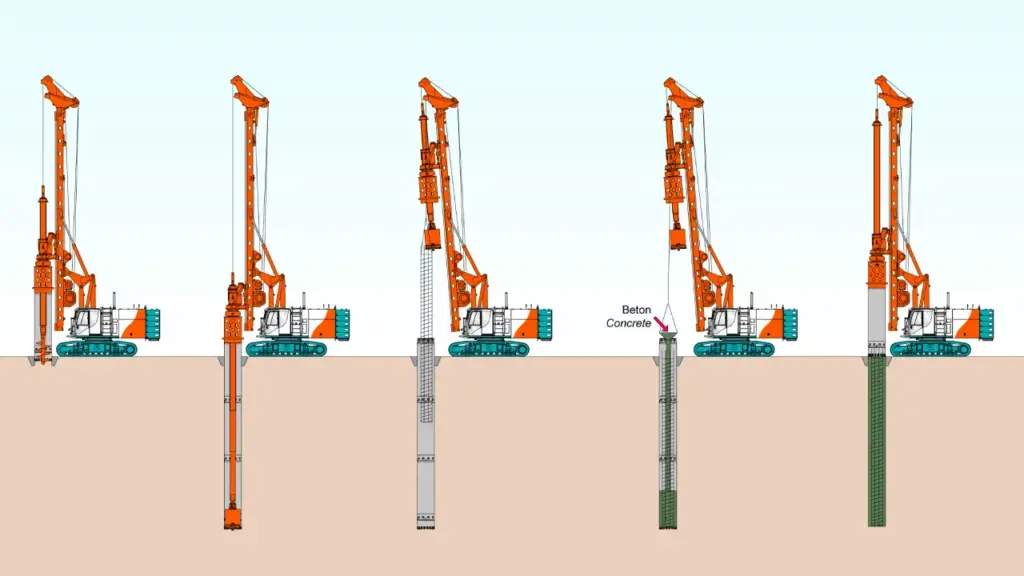

Core Drilling

Core drilling is a specialized type of drilling that cuts a cylindrical core of material while leaving a hole. An annular drill bit, which is hollow in the center, is used to achieve this. The cutting edges are located on the periphery of the bit, and as it rotates and advances, a solid core sample is extracted.

Benefits: Core drilling allows for the retrieval of intact material samples, which is invaluable for geological analysis, material testing, and forensic investigations. It can also be more efficient for creating large diameter holes as it removes less material overall.

Uses: This method is primarily used in geological surveys to obtain rock and soil samples, in construction for creating openings for pipes and ducts while preserving the surrounding material, and in scientific research for analyzing material structures.

Auger Drilling

Auger drilling uses a helical screw blade, called an auger, to bore into softer materials like soil and unconsolidated sediments. As the auger rotates, the helical flights lift the drilled material out of the hole. This method is relatively simple and efficient for shallow to medium-depth drilling in suitable ground conditions.

Benefits: Auger drilling is a cost-effective and rapid method for drilling in soft materials. The auger action provides efficient removal of cuttings, and the equipment is generally less complex than other drilling rigs.

Uses: This technique is widely employed for soil sampling, installing fence posts and signposts, and drilling shallow wells. It is also used in construction for foundation work and environmental investigations.

Sonic Drilling

Sonic drilling utilizes high-frequency vibrations to advance a drill bit or core barrel into the ground. The vibrations reduce friction between the drilling tool and the surrounding material, allowing for faster penetration with less downward force. This method can be effective in a variety of soil and unconsolidated formations.

Benefits: Sonic drilling can achieve relatively high penetration rates and is effective in diverse soil types. It often produces minimal soil disturbance and can provide continuous core samples with good integrity.

Uses: This method is used for environmental sampling, geotechnical investigations, and the installation of wells and monitoring equipment. Its ability to minimize disturbance makes it suitable for sensitive environments.

Thermal Drilling

Thermal drilling employs heat to melt or vaporize material. Different energy sources, such as lasers or plasma torches, can be used to generate the intense heat required. This method is often used for drilling in specialized materials where conventional mechanical methods may be difficult or inefficient.

Benefits: Thermal drilling can create holes in very hard or brittle materials without physical contact, reducing tool wear. It can also achieve high precision and intricate shapes in certain applications.

Uses: Laser drilling is used in manufacturing for creating small, precise holes in metals and composites. Plasma arc drilling is employed for cutting and piercing thick metallic materials.

Electron Beam Drilling (EBD)

Electron beam drilling uses a focused beam of high-velocity electrons to melt and vaporize material. The process is typically carried out in a vacuum to prevent scattering of the electron beam. EBD can create very small and precise holes in a wide range of materials.

Benefits: EBD offers exceptional precision and the ability to drill very small diameter holes with high aspect ratios. It can be used on a variety of materials, including metals, ceramics, and plastics.

Uses: This method is employed in aerospace and electronics industries for creating fine holes in turbine blades, microelectronic components, and medical devices.

Electrochemical Drilling (ECD)

Electrochemical drilling removes metal by anodic dissolution in an electrolytic cell. The workpiece acts as the anode, and a shaped tool acts as the cathode. An electrolyte solution flows between the tool and the workpiece, and when a current is passed, metal ions are removed from the workpiece surface, creating a hole that mirrors the shape of the tool.

Benefits: ECD is a non-contact process, eliminating tool wear and mechanical stresses on the workpiece. It can produce complex shapes and is suitable for machining hard and brittle metals.

Uses: This method is used in aerospace and automotive industries for machining complex contours, turbine blades, and intricate parts where conventional machining might be difficult or cause damage.

Here is a table showing you the basic info about the popular drilling methods:

| Drilling Method | Mechanism | Key Benefits | Typical Uses |

| DTH Drilling | Pneumatic hammer behind the bit impacts and rotates. Compressed air flushes cuttings. | Effective in hard rock, high penetration rates in tough conditions, straighter boreholes. | Mining (blast holes), quarrying, construction (hard rock foundations), water well drilling (consolidated formations). |

| Rotary Drilling | Rotating drill bit shears material. Air or mud can be used for cutting removal. | Versatile for various materials, relatively fast, good control over hole dimensions, adaptable equipment. | Geotechnical/environmental investigations, oil/gas exploration, water well drilling, construction (foundations, ground anchors). |

| Percussion Drilling | Rotating bit combined with hammering action fractures material. | Efficient in hard materials, faster drilling in rock and concrete. | Construction (anchors, dowels, blasting), mining and quarrying (exploration and extraction boreholes). |

| Diamond Drilling | Rotating bit with embedded diamonds abrades material. Coolant usually required. | Cuts very hard/abrasive materials, high precision, smooth holes, less heat with cooling. | Geological exploration (core sampling), semiconductor industry, construction (reinforced concrete, tile). |

| Core Drilling | Annular rotating bit cuts a cylindrical core, leaving a hole and a sample. | Retrieves intact material samples, efficient for large diameter holes (less material removal). | Geological surveys (rock/soil samples), construction (pipe/duct openings), scientific research (material analysis). |

| Auger Drilling | Helical screw blade (auger) rotates to bore into soft materials and lift cuttings. | Cost-effective in soft materials, rapid drilling, simple equipment. | Soil sampling, installing fence/sign posts, shallow wells, construction (foundation work), environmental investigations. |

| Sonic Drilling | High-frequency vibrations advance the bit/core barrel, reducing friction. | High penetration rates in diverse soils, minimal disturbance, good continuous core samples. | Environmental sampling, geotechnical investigations, installing wells/monitoring equipment, sensitive environments. |

| Thermal Drilling | Heat (laser, plasma) melts or vaporizes material. | Non-contact, reduced tool wear, high precision, intricate shapes in specialized materials. | Manufacturing (small precise holes in metals/composites), cutting/piercing thick metallic materials (plasma arc). |

| Electron Beam Drilling | Focused beam of high-velocity electrons melts/vaporizes material in a vacuum. | Exceptional precision, very small diameter holes with high aspect ratios, variety of materials. | Aerospace (turbine blades), electronics (microelectronic components), medical devices. |

| Electrochemical Drilling | Anodic dissolution removes metal using an electrolytic cell (non-contact). | No tool wear/mechanical stress, complex shapes, suitable for hard/brittle metals. | Aerospace/automotive (complex contours, turbine blades, intricate parts). |

What Are the Two Most Common Types of Drilling Method

The two most common types of drilling methods, widely utilized across various industries, are rotary drilling and percussion drilling. These techniques represent fundamental approaches to creating boreholes, each relying on distinct mechanical actions to penetrate and remove material.

Their prevalence stems from their adaptability to a broad range of materials and project requirements, coupled with the availability of diverse equipment and expertise.

Rotary drilling employs a rotating drill bit that cuts or grinds its way through the material. This method is characterized by the continuous rotation of the bit under applied pressure, efficiently shearing or abrading the substrate to create a cylindrical hole. Rotary drilling is versatile and can be adapted for drilling in soil, rock, and even softer materials like wood and plastic by using different bit types and drilling parameters.

Percussion drilling, in contrast, combines a rotary action with a hammering or impact force to fracture and pulverize the material. The drill bit is repeatedly struck while it rotates, delivering high-energy impacts to the drilling surface. This method is particularly effective for penetrating hard and brittle materials such as rock and concrete, where the percussive action helps overcome the material’s resistance to continuous cutting.

How to Choose the Most Suitable Drilling Method

Selecting the most suitable drilling method hinges on a careful evaluation of project-specific requirements and the characteristics of the material being drilled.

Key factors to consider include the hardness and abrasiveness of the target material, the desired hole diameter and depth, the required precision and finish, and any environmental constraints or accessibility limitations of the site. Additionally, project budget and the availability of specific drilling equipment and expertise will significantly influence the decision-making process.

To make an informed choice, systematically assess these critical aspects:

- Material Properties: Analyze the hardness, compressive strength, and abrasiveness of the material. Harder materials often necessitate methods like DTH or diamond drilling, while softer materials may be efficiently drilled with rotary or auger techniques. Consider potential variations within the drilling area.

- Hole Specifications: Determine the required diameter, depth, and tolerance of the borehole. Large diameter or deep holes might favor rotary or DTH drilling, while high-precision applications could benefit from diamond or electron beam drilling. The desired wall finish should also be considered.

- Project Constraints: Evaluate site accessibility, environmental regulations, and budget limitations. Some methods are more portable or generate less noise/vibration, which can be crucial in certain locations. Cost-benefit analysis of equipment and operational expenses is essential for project feasibility.

Conclusion

Drilling Method selection is crucial for project success. Understanding the nuances of each technique—rotary, percussion, and others—ensures efficiency and cost-effectiveness. Carefully consider material, depth, and environmental factors to make an informed choice.

Ultimately, the optimal Drilling Method directly impacts project timelines and outcomes. Investing in high-quality tools enhances performance and longevity. Explore the premium selection of drilling tools available at Sinodrills to equip your projects for success.

Choosing wisely and using reliable equipment, like that offered by Sinodrills, will lead to more efficient and successful drilling operations. Don’t compromise on quality when it comes to your essential drilling needs.