Custom Duplex Coating Rock Bolt Manufacturer in China

We offer duplex coating rock bolts, which combine hot-dip galvanizing with a durable powder coating for maximum corrosion protection. This dual-layer system is engineered to provide an extended service life in highly corrosive and aggressive environments. Our duplex-coated bolts deliver superior long-term performance, ensuring the safety and stability of your geotechnical and mining projects.

Sinodrills - Your Trusted Duplex Coating Rock Bolt Manufacturer from China

Sinodrills is your premier manufacturer of duplex coating rock bolts from China, providing unparalleled corrosion resistance. We combine hot-dip galvanizing with a protective powder coating, ensuring our rock bolts withstand the most aggressive environments. Our commitment to quality and durability makes us a trusted partner for geotechnical and mining projects that demand long-term stability and safety.

Duplex Coating Rock Bolt Benefits

Superior Corrosion Resistance: The combination of zinc from hot-dip galvanizing and the polymer from powder coating creates a robust barrier. This dual protection significantly extends the life of the rock bolt in highly corrosive environments.

Enhanced Durability: The outer powder coating provides an extra layer of protection against mechanical damage, such as scratches and abrasion. This protects the underlying zinc layer from being compromised during installation or downhole stresses.

Aesthetic and Versatile: The powder coating can be applied in various colors, which can be useful for aesthetic purposes or for color-coding bolts by size or application. This offers more flexibility in project design.

Longer Service Life: The synergistic effect of the two coatings—with the powder coating protecting the zinc and the zinc protecting the steel—provides a service life that is significantly longer than either coating alone.

Reduced Maintenance: The enhanced longevity of duplex-coated bolts reduces the need for frequent inspections and maintenance. This results in lower long-term costs and less operational downtime for geotechnical projects.

Duplex Coating Rock Bolt Applications

Tunneling and Mining: Used in tunnels and mines where high humidity, groundwater, and exposure to corrosive chemicals are common. The duplex coating protects the bolt from degradation, ensuring long-term structural integrity.

Marine and Coastal Construction: Ideal for seawalls, piers, and other structures exposed to saltwater spray and high chloride content. The dual-layer coating prevents corrosion caused by the harsh marine environment.

Geotechnical and Slope Stabilization: Employed in stabilizing slopes and retaining walls that are exposed to acidic soils or polluted groundwater. It provides reliable, long-term support for preventing landslides and erosion.

Foundation and Building Construction: Used in foundations and structural applications where bolts are in contact with concrete or soil, which can be corrosive over time. The coating guarantees the durability of the anchor over the building’s lifespan.

Customize Your Desired Duplex Coating Rock Bolt

Bolt Length and Diameter

We help you select the precise length and diameter for your Duplex Coating Rock Bolts. By customizing these dimensions, we ensure each bolt can handle the specific load requirements of your project, providing maximum stability and safety for rock reinforcement under varying pressure conditions.

Coating Thickness

We adjust the duplex coating thickness according to environmental and corrosion demands. Thicker coatings offer extended protection in highly corrosive or humid conditions, while standard coatings suit normal environments. We ensure each bolt is protected effectively, prolonging service life and maintaining structural integrity.

Thread Type and Pitch

We customize the thread type and pitch of our rock bolts to match installation equipment and rock types. Proper threading ensures secure anchoring, reduces installation time, and improves load transfer efficiency. We provide tailored threading options to fit every engineering requirement precisely.

Material Grade

We offer Duplex Coating Rock Bolts in various material grades to suit different stress and environmental conditions. Choosing the right material ensures optimal strength, corrosion resistance, and durability. We work closely with clients to select the best grade for long-term safety and performance.

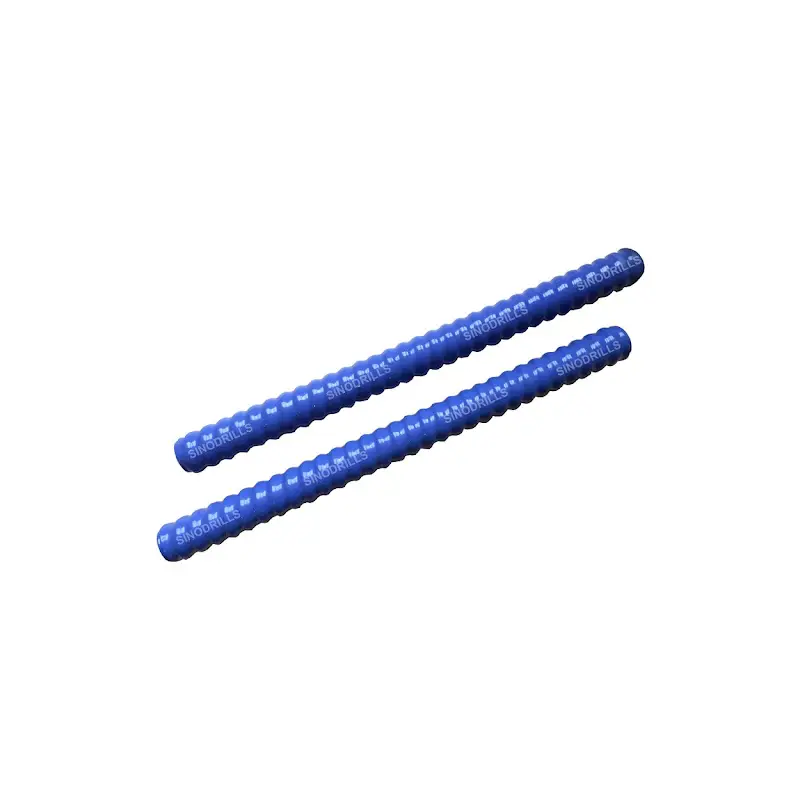

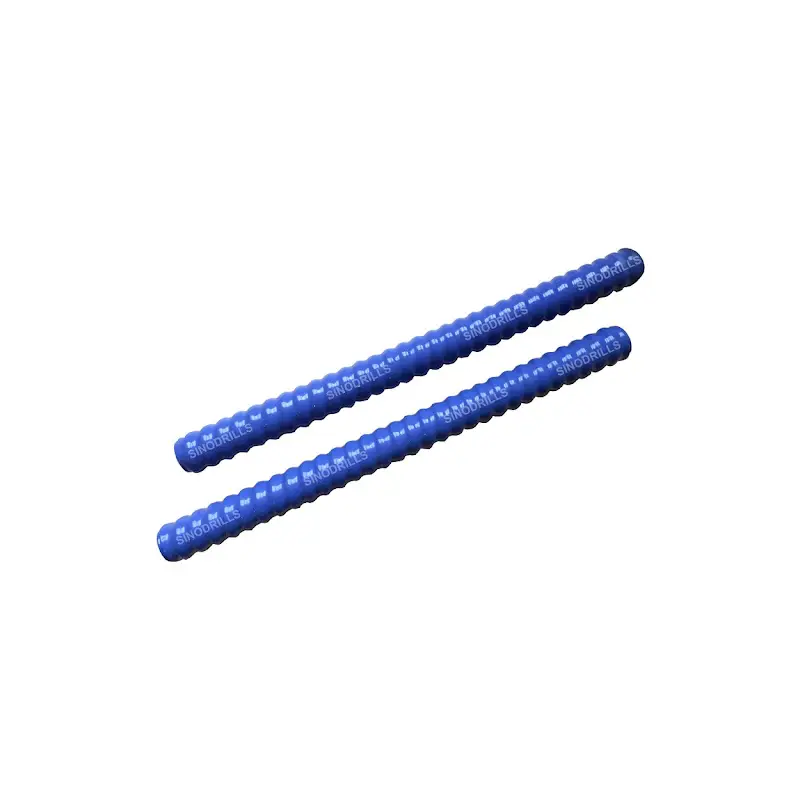

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

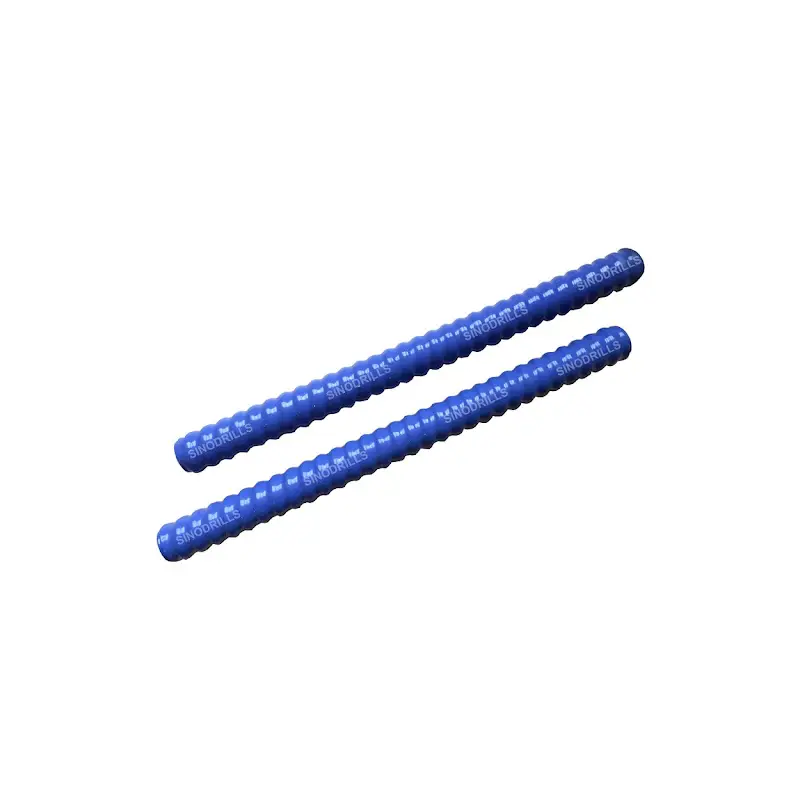

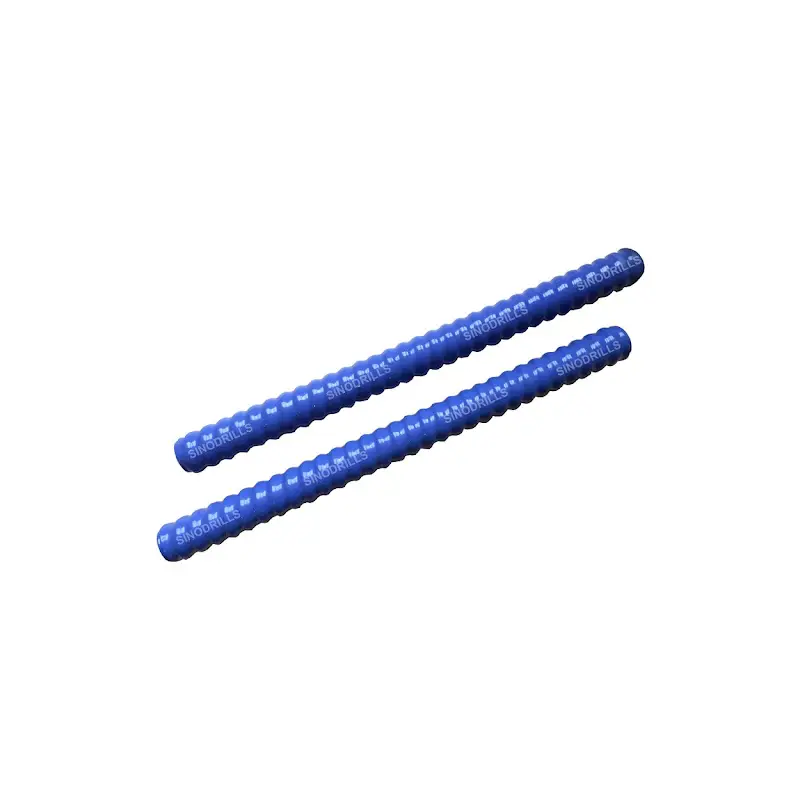

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

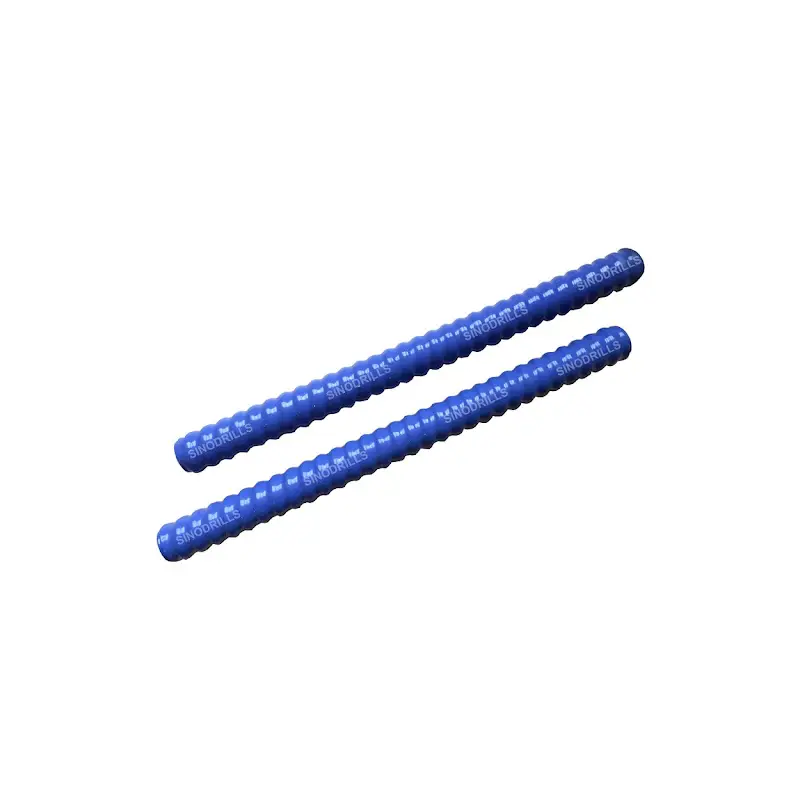

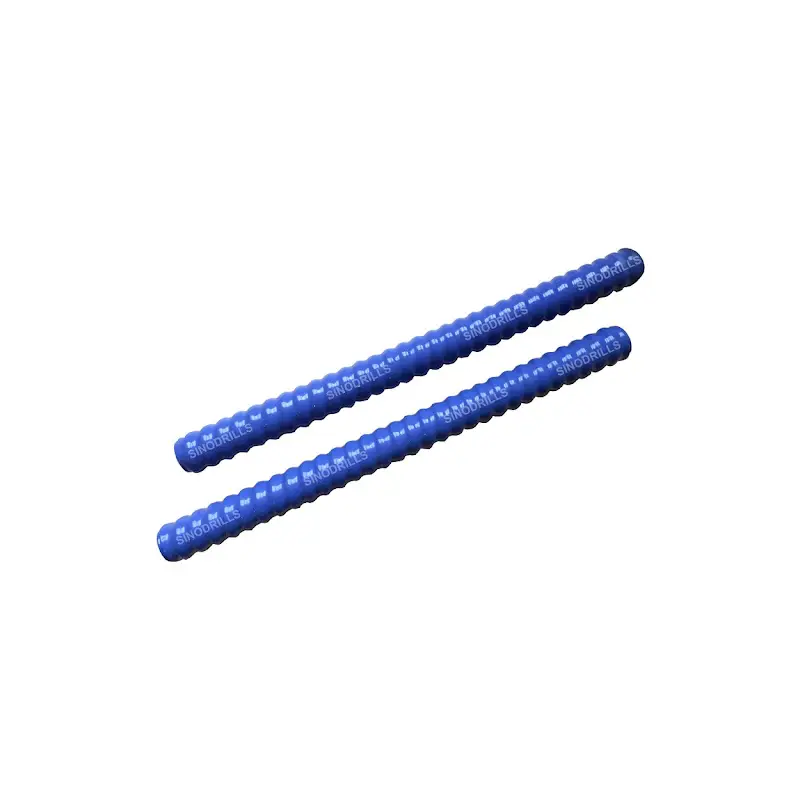

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

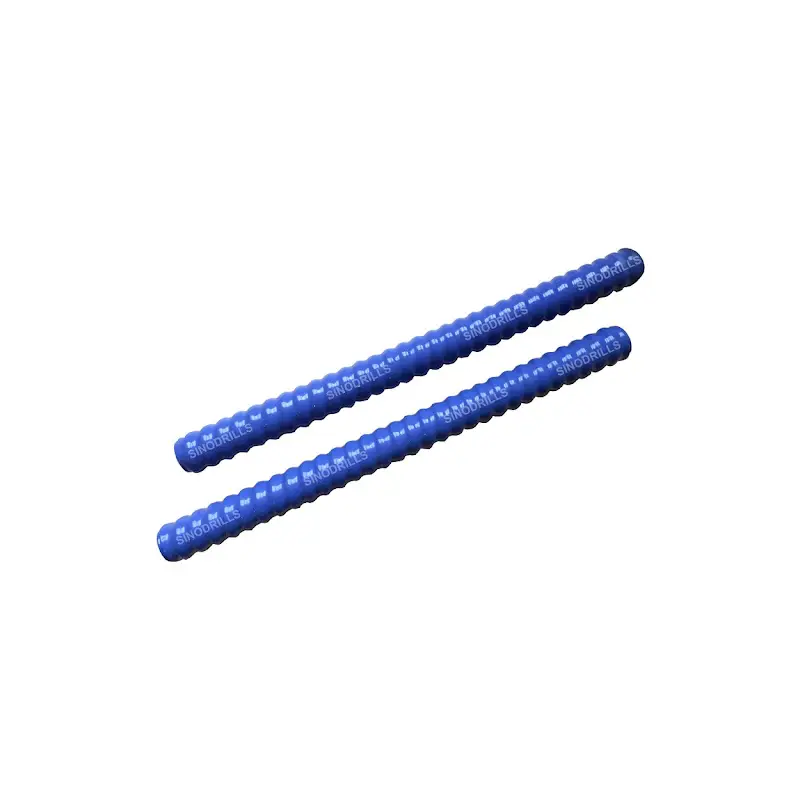

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

Duplex Coated Rock Drill Bolts

We offer duplex coated rock drill bolts built for strong corrosion resistance and long-term performance in tunnels, mines, and slope stabilization projects. The dual-layer protection helps the bolts withstand moisture, abrasion, and harsh ground chemistry. With consistent sizing, dependable bonding, and smooth installation, our bolts support reliable reinforcement across demanding geological environments.

What is a duplex coating in drilling?

In drilling and geotechnical applications, a duplex coating refers to a dual-layer corrosion protection system applied to steel components, such as rock bolts or anchors. This system involves a base layer of hot-dip galvanizing, which provides cathodic protection to the steel, followed by a top layer of a powder coating.

The two layers work synergistically: the powder coating acts as a barrier, protecting the zinc layer from wear and tear, while the zinc layer provides a sacrificial defense against corrosion if the powder coating is scratched.

This combination significantly extends the service life of the steel component, making it highly suitable for aggressive and corrosive environments.

What is the difference between rock bolts and rock dowels?

Rock bolts and rock dowels are both used for stabilizing rock masses, but they function in fundamentally different ways. The primary distinction lies in how they are engaged to provide support.

A rock bolt is an “active” reinforcement element. It is actively tensioned after installation, which creates a compressive force in the surrounding rock mass. This pre-stressing increases the rock’s shear capacity and provides immediate support without any ground movement.

Conversely, a rock dowel is a “passive” reinforcement element. It is installed untensioned and only becomes active when a rock mass moves, which then generates tensile and shear forces in the dowel to resist further displacement.

Activation: Rock bolts are active; they are tensioned and provide immediate support. Rock dowels are passive; they only provide support after a degree of rock mass movement occurs.

Support Mechanism: Rock bolts create an active compressive force in the rock. Rock dowels resist movement through their tensile and shear strength, which is engaged by rock mass displacement.

Installation: Rock bolts typically require a mechanical or chemical anchor and a tensioning step. Rock dowels are simpler to install, often consisting of a steel bar fully grouted into the borehole without tensioning.

What is duplex coating anchor bolt used for?

A duplex coating anchor bolt is a specialized anchor used in applications where long-term corrosion resistance is paramount. By combining a base layer of hot-dip galvanizing with an outer powder coating, this system provides a synergistic effect that offers a significantly longer service life than either coating alone.

The powder coating acts as a durable barrier, protecting the underlying zinc, while the zinc provides cathodic protection for the steel, even if the outer layer is scratched. This makes duplex-coated bolts the ideal choice for projects in aggressive and corrosive environments where maintenance and replacement are difficult or costly.

Tunnels and Underground Structures: Used in subway tunnels and other underground projects where high humidity, groundwater, and corrosive chemicals from the soil can cause rapid degradation. The coating protects the bolts from continuous exposure to a harsh environment.

Marine and Coastal Environments: Ideal for use in marine infrastructure, such as wharves, ports, and offshore structures. The duplex coating provides robust protection against the corrosive effects of saltwater and chlorides.

Slope Stabilization: Employed in stabilizing slopes and retaining walls, especially in areas with acidic soil or contaminated groundwater. The coating ensures the long-term integrity of the anchor, preventing landslides and erosion.

Hydroelectric and Water Conservancy Projects: Used in dams, locks, and other water-related infrastructure that are constantly exposed to water and varying pH levels. The duplex coating ensures durability and prevents structural failure due to corrosion.

why choose our duplex coating anchor bolts?

Choose our duplex coating anchor bolts for superior, long-lasting corrosion protection that ensures the integrity and safety of your projects in even the harshest environments. The synergistic combination of a hot-dip galvanized base and a durable powder coating provides a dual-layer defense against rust, abrasion, and chemical attack.

This makes our bolts an excellent investment for applications demanding reliability and minimal maintenance over their service life.

Enhanced Durability: Our dual-layer coating is significantly more resistant to mechanical damage from installation or downhole stresses than a single-layer coating, protecting the underlying steel more effectively.

Extended Service Life: The duplex system’s combined protection extends the bolt’s lifespan far beyond that of a traditional galvanized or powder-coated bolt, reducing the need for costly replacements.

Versatility: Our bolts are suitable for a wide range of aggressive applications, including tunnels, coastal structures, and projects in corrosive soils.

Customization: We offer customized dimensions, steel grades, and coating thicknesses to meet the specific requirements of your project.

how to choose our duplex coating anchor bolts?

Choosing the right Duplex Coating Anchor Bolts is essential for durability, corrosion resistance, and safety in construction and mining projects.

We guide you to select bolts that meet your load, environmental, and installation requirements, ensuring long-term performance and secure fastening under all conditions.

-

Project Requirements and Load Capacity: We evaluate your project’s specific load demands and structural needs, selecting anchor bolts with the correct strength and dimensions. We ensure each bolt withstands operational pressures, maintains rock or concrete stability, and provides long-term safety for your construction or mining applications.

-

Environmental Conditions: We assess factors such as humidity, chemical exposure, and temperature changes. Duplex Coating Anchor Bolts are customized with coatings and materials that resist corrosion and wear. We ensure each bolt maintains protective performance even in harsh or highly corrosive environments, maximizing service life.

-

Installation Method: We consider your installation techniques and equipment. Choosing anchor bolts compatible with drilling and fastening processes ensures proper anchoring, easier installation, and efficient load transfer. We guide bolt selection for thread type, design, and length to achieve optimal results in your projects.

-

Material and Coating Selection: We help select the ideal material grade and duplex coating thickness for maximum durability. Proper selection prevents corrosion, extends service life, and maintains structural integrity. We work closely with clients to match materials to environmental conditions and load requirements precisely.

Send Your Inquiry Now

All-in-one Duplex Coating Rock Bolt Solutions for Your Project

We offer all-in-one duplex coating rock bolt solutions for your project’s toughest challenges. Our duplex coating bolts combine hot-dip galvanizing and powder coating for a superior, long-lasting defense against corrosion. This ensures optimal safety, extended service life, and reduced maintenance costs for all your geotechnical and mining applications.