Custom Eccentric Drilling Reamer Manufacturer in China

We offer eccentric drilling reamers designed for precise hole enlargement in mining, tunneling, and construction projects. Our reamers provide smooth operation, accurate drilling, and enhanced efficiency in challenging conditions. With durable materials and reliable design, we supply eccentric drilling reamers that meet your project requirements, ensuring consistent performance and long service life.

Sinodrills - Your Trusted Eccentric Drilling Reamer Manufacturer from China

Sinodrills supplies high-performance eccentric drilling reamers for mining, tunneling, and construction projects. We focus on precision engineering, durability, and reliable performance, ensuring efficient hole enlargement in various rock formations. With advanced manufacturing and strict quality control, we provide customized solutions and technical support, helping you achieve smooth, accurate, and cost-effective drilling results for every project.

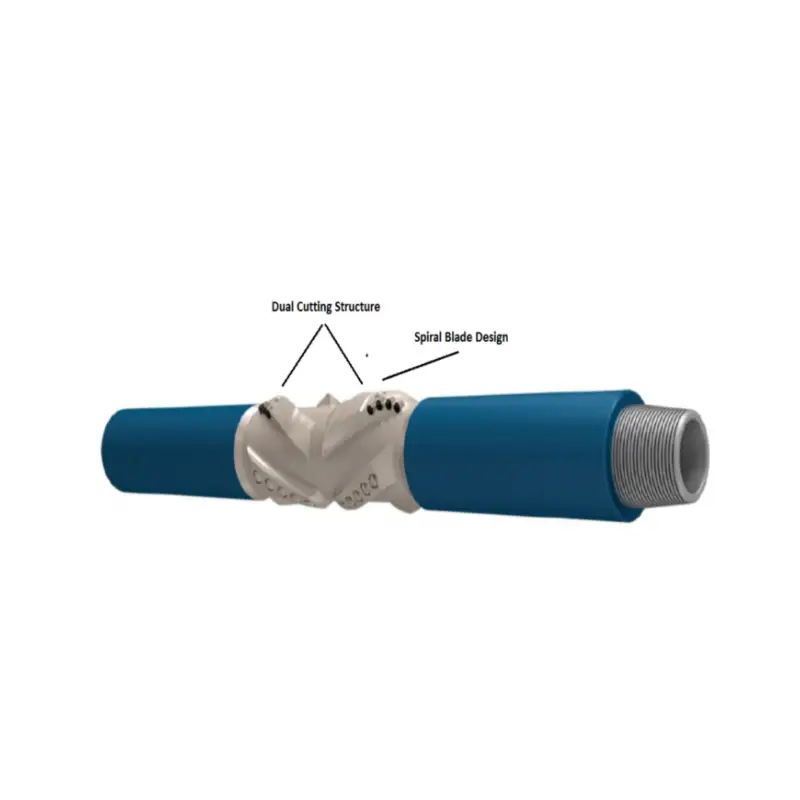

Eccentric Drilling Reamer Components

Body: The main cylindrical part of the tool, usually made from high-strength steel. It houses the internal mechanisms and provides the structural integrity for the reamer to withstand downhole forces.

Cutting Blades/Wings: The spiraled, often replaceable, cutting structures that extend from the body. They are designed to enlarge the drilled hole to a precise, pre-determined diameter.

Pilot/Drill Bit: A smaller-diameter section at the front (not visible in this image) that guides the reamer. It initially drills the hole, and the reamer’s blades then follow to expand it.

Connection Threads: The threaded ends of the tool used to connect it to the drill string on one side and a pilot bit or another tool on the other. They ensure a secure and reliable link.

Eccentric Drilling Reamer Benefits

Precise Hole Enlargement – Eccentric drilling reamers provide accurate hole expansion, allowing for uniform diameters and smooth surfaces, which ensures better fitment for bolts, casings, or construction components.

Improved Drilling Efficiency – By optimizing rock removal and minimizing resistance, eccentric reamers reduce drilling time, lower operational costs, and enhance overall efficiency in mining, tunneling, and construction projects.

Durable and Reliable – Built from strong materials, eccentric drilling reamers withstand harsh drilling conditions, providing long-lasting performance, consistent results, and reduced maintenance or replacement frequency.

Versatile Applications – Suitable for various rock types and project needs, these reamers can be used in mining, tunnel excavation, and foundation drilling, adapting to different hole sizes and geological conditions.

Enhanced Safety – Eccentric drilling reamers allow controlled, stable drilling, reducing the risk of accidents and ensuring safer operations for workers in demanding drilling environments.

Eccentric Drilling Reamer Components

Mining Operations – Eccentric drilling reamers are used to enlarge drilled holes in mining projects, providing precise rock removal and improving efficiency in ore extraction processes.

Tunneling Projects – These reamers assist in tunnel construction by accurately widening pilot holes, ensuring smooth excavation, better alignment, and reduced equipment wear during underground development.

Construction Foundations – Eccentric drilling reamers are applied in foundation work for large buildings and infrastructure, enabling precise hole enlargement for piles, anchors, and other structural supports.

Geotechnical Exploration – They are used in site investigations to expand boreholes, allowing collection of geological data, soil sampling, and testing while maintaining stability and accurate hole dimensions.

Pipeline and Utility Installation – Eccentric reamers help enlarge drilling paths for pipelines or underground utilities, ensuring smooth installation, minimal obstruction, and reliable alignment throughout construction projects.

Customize Your Desired Eccentric Drilling Reamer

Diameter and Size

We customize the diameter and overall size of eccentric drilling reamers according to your project requirements. By adjusting dimensions, we ensure accurate hole enlargement, optimal drilling efficiency, and compatibility with your existing drilling rigs and equipment.

Blade Type and Material

We select and tailor blade types and materials based on the rock formation and drilling conditions. By using durable steel or tungsten carbide blades, we enhance cutting performance, wear resistance, and long-lasting reliability for efficient reaming operations.

Offset and Eccentricity

We adjust the offset and eccentricity of the reamer to meet specific drilling objectives. By fine-tuning these parameters, we optimize hole enlargement, improve stability during operation, and ensure precise control in complex or irregular rock formations.

Connection and Threading

We customize the connection type and threading of eccentric drilling reamers for compatibility with your drill rods and rigs. This ensures secure attachment, smooth rotation, and reliable performance during drilling and reaming tasks.

what is eccentric drilling reamer?

An eccentric drilling reamer is a specialized drilling tool used to enlarge or smooth existing boreholes in mining, construction, and tunneling projects.

Featuring offset or eccentric blades, it removes additional material around the initial hole to achieve precise diameter and improved hole quality. Designed for durability and efficient cutting, eccentric drilling reamers provide smooth operation, maintain alignment, and enhance overall drilling performance in various rock and soil conditions, making them essential for accurate and cost-effective drilling and excavation tasks.

what are different types of rock drilling reamers?

Rock drilling reamers are specialized tools designed to enlarge and smooth drilled holes in mining, construction, and tunneling projects. Selecting the right type ensures efficient drilling, precise hole diameter, and optimal performance in various rock formations and geological conditions.

Eccentric Reamers – Eccentric reamers feature offset blades to enlarge boreholes beyond the initial drill size. We design them to provide smooth, controlled cutting, improved alignment, and precise hole diameter, ensuring efficient reaming in challenging rock formations and complex drilling conditions.

Conical Reamers – Conical reamers have a tapered design for gradual hole enlargement. We provide them to ensure even material removal, reduced stress on drill rods, and accurate borehole shaping for mining, tunneling, and construction applications.

Shell Reamers – Shell reamers are cylindrical tools used for uniform hole enlargement. We manufacture them with durable cutting edges and optimized geometry to provide consistent hole diameter, smooth walls, and efficient rock removal in large-scale drilling operations.

Roller Reamers – Roller reamers use rotating rollers to grind and enlarge drilled holes. We supply them with precision-engineered rollers for effective material removal, enhanced stability, and long-lasting performance in hard rock and abrasive formations.

Fixed-Blade Reamers – Fixed-blade reamers feature stationary cutting edges for controlled hole enlargement. We provide them with durable, high-strength materials and optimized design to ensure precise drilling, reduced vibration, and improved overall efficiency in rock drilling projects.

Send Your Inquiry Now

All-in-one Eccentric Drilling Reamer Solutions for Your Project

We provide all-in-one eccentric drilling reamer solutions for your project, covering design, customization, and supply. Our reamers deliver precise hole enlargement, durability, and reliable performance for mining, tunneling, and construction applications. With expert support and tailored specifications, we ensure your eccentric drilling reamers maximize efficiency and meet all project requirements.