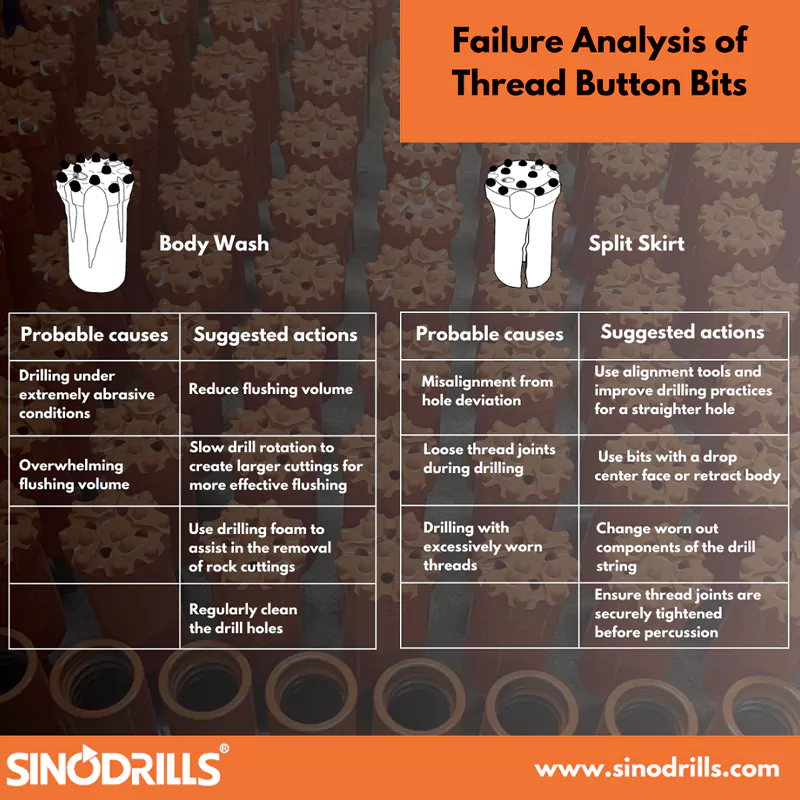

1. Body Wash

Probable causes:

– Drilling under extremely abrasive conditions

– Overwhelming flushing volume

Suggested actions:

– Reduce flushing volume

– Slow drill rotation to create larger cuttings for more effective flushing

– Use drilling foam to assist in the removal of rock cuttings

– Regularly clean the drill holes

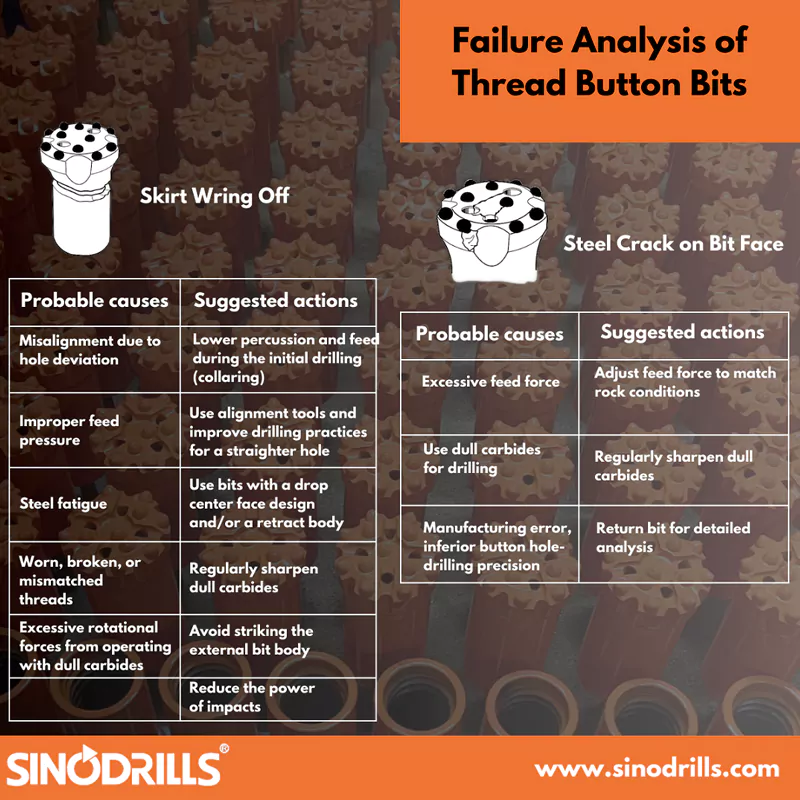

2. Skirt Wring Off

Probable causes:

– Misalignment due to hole deviation

– Improper feed pressure

– Steel fatigue

– Worn, broken, or mismatched threads

– Excessive rotational forces from operating with dull carbides

Suggested actions:

– Lower percussion and feed during the initial drilling (collaring)

– Use alignment tools and improve drilling practices for a straighter hole; Use bits with a drop center face design and/or a retract body

– Regularly sharpen dull carbides

– Avoid striking the external bit body

– Reduce the power of impacts

3. Split Skirt

Probable causes:

– Misalignment from hole deviation

– Loose thread joints during drilling

– Drilling with excessively worn threads

Suggested actions:

– Use alignment tools and improve drilling practices for a straighter hole

– Use bits with a drop center face or retract body

– Change worn out components of the drill string

– Ensure thread joints are securely tightened before percussion

4. Steel Crack on Bit Face

Probable causes:

– Excessive feed force

– Use dull carbides for drilling

– Manufacturing error, inferior button hole-drilling precision

Suggested actions:

– Adjust feed force to match rock conditions

– Regularly sharpen dull carbides

– Return bit for detailed analysis

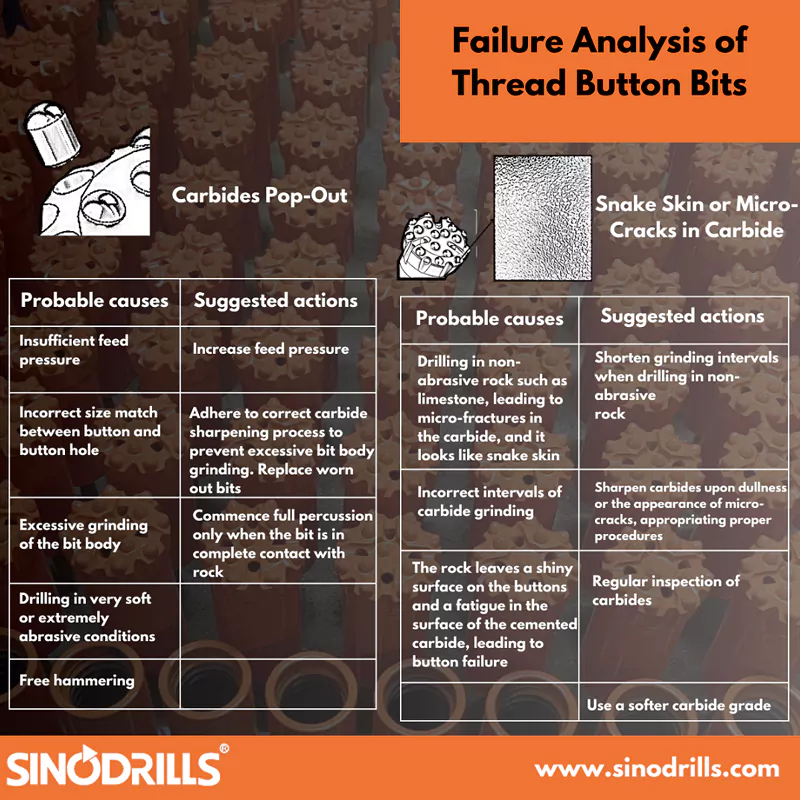

5. Carbides Pop-Out

Probable causes:

– Insufficient feed pressure

– Incorrect size match between button and button hole

– Excessive grinding of the bit body

– Drilling in very soft or extremely abrasive conditions

– Free hammering

Suggested actions:

– Increase feed pressure

– Adhere to correct carbide sharpening process to prevent excessive bit body grinding. Replace worn out bits.

– Commence full percussion only when the bit is in complete contact with rock

6. Snake Skin or Micro-Cracks in Carbide

Probable causes:

– Drilling in non-abrasive rock such as limestone, leading to micro-fractures in the carbide, and it looks like snake skin.

– Incorrect intervals of carbide grinding

– The rock leaves a shiny surface on the buttons and a fatigue in the surface of the cemented carbide, leading to button failure

Suggested actions:

– Shorten grinding intervals when drilling in non-abrasive

rock

– Sharpen carbides upon dullness or the appearance of micro-cracks, appropriating proper procedures

– Regular inspection of carbides

– Use a softer carbide grade

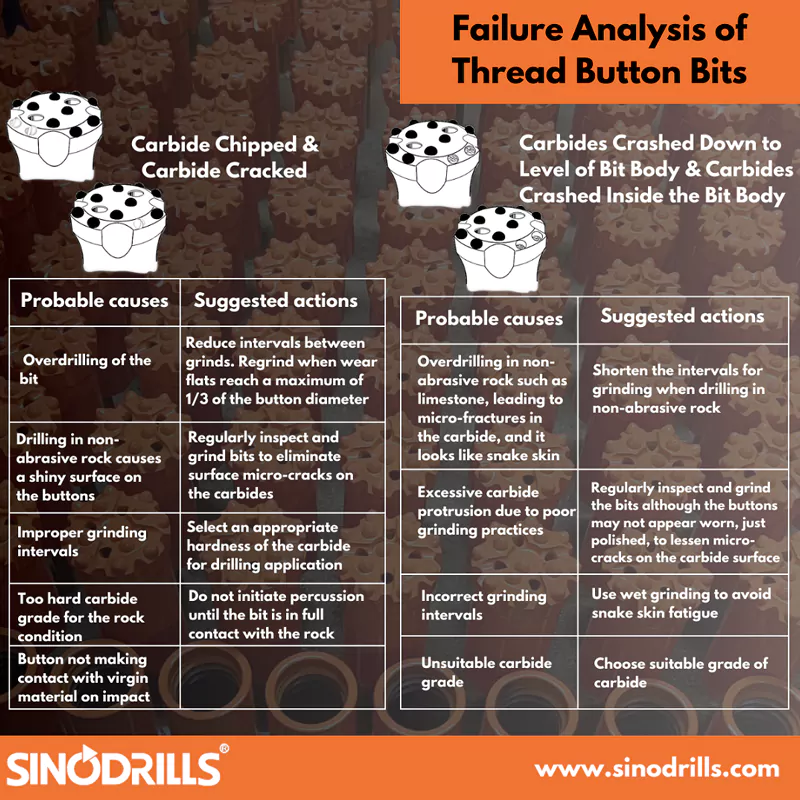

7. Carbide Chipped & Carbide Cracked

Probable causes:

– Overdrilling of the bit

– Drilling in non-abrasive rock causes a shiny surface on the buttons

– Improper grinding intervals

– Too hard carbide grade for the rock condition

– Button not making contact with virgin material on impact

Suggested actions:

– Reduce intervals between grinds. Regrind when wear flats reach a maximum of 1/3 of the button diameter

– Regularly inspect and grind bits to eliminate surface micro-cracks on the carbides

– Select an appropriate hardness of the carbide for drilling application

– Do not initiate percussion until the bit is in full contact with the rock

8. Carbides Crashed Down to Level of Bit Body & Carbides Crashed Inside the Bit Body

Probable causes:

– Overdrilling in non-abrasive rock such as limestone, leading to micro-fractures in the carbide, and it looks like snake skin.

– Excessive carbide protrusion due to poor grinding practices

– Incorrect grinding intervals

– Unsuitable carbide grade

Suggested actions:

– Shorten the intervals for grinding when drilling in non-abrasive rock

– Regularly inspect and grind the bits although the buttons may not appear worn, just polished, to lessen micro-cracks on the carbide surface

– Use wet grinding to avoid snake skin fatigue

– Choose suitable grade of carbide