Foundation drilling is a critical discipline in modern civil engineering, a specialized process that lays the groundwork for some of the world’s most impressive structures. It involves creating deep, precise holes in the earth to install robust foundation systems. This work is essential for ensuring that massive buildings, bridges, and other heavy structures are built on a secure and stable base that can withstand incredible loads.

Without proper foundation drilling, structures would be vulnerable to shifting, settling, and potential collapse. The techniques and technologies involved have evolved significantly, allowing engineers to overcome complex geological challenges. Understanding this process is key to appreciating how major construction projects achieve both stability and longevity.

What is Foundation Drilling?

Foundation drilling is a specialized civil engineering process used to create deep, large-diameter holes in the ground to prepare for the installation of a building’s foundation. This technique is critical for major construction projects, such as skyscrapers, bridges, and dams, where the sheer weight of the structure cannot be supported by shallow surface soil.

The primary purpose of foundation drilling is to transfer the load from the building to a stable, load-bearing layer of soil or bedrock located deep beneath the surface, ensuring the long-term stability and structural integrity of the entire construction project.

How Does Foundation Drilling Work?

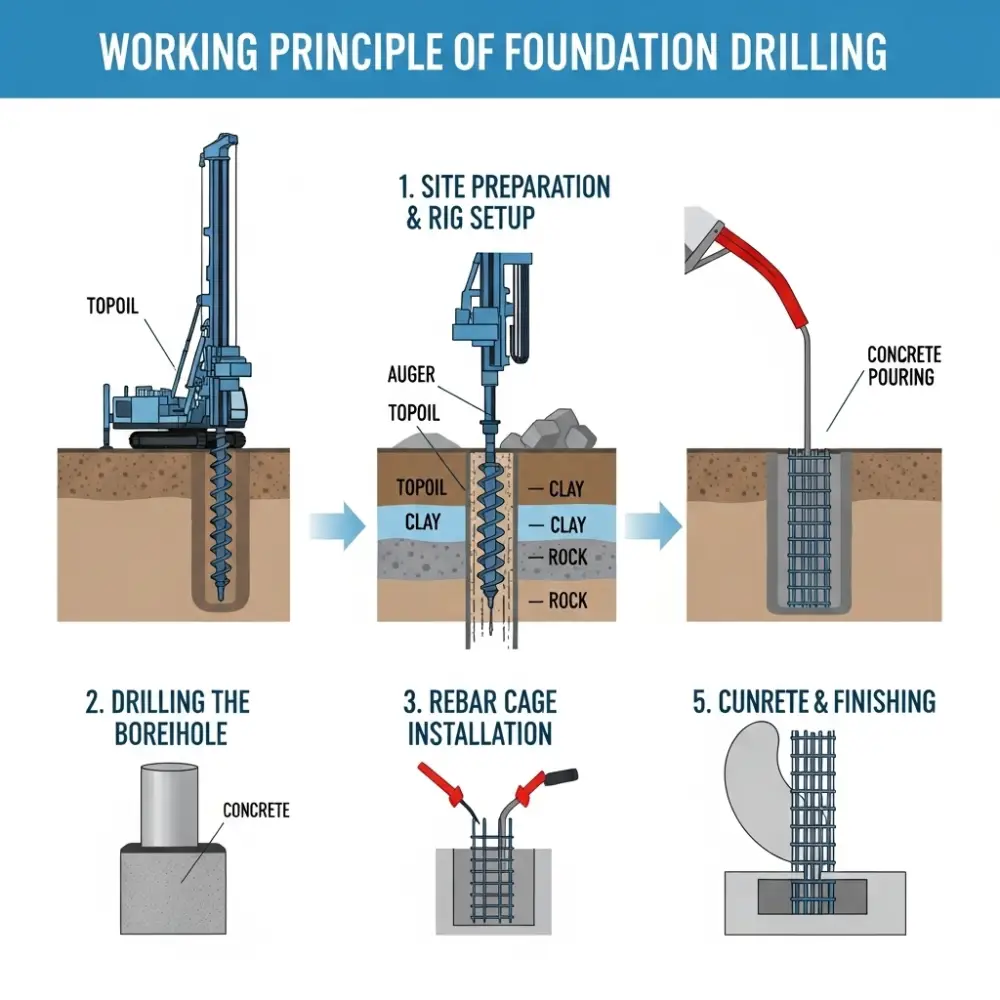

Foundation drilling is a complex process that involves using specialized machinery and techniques to create deep, stable holes for a structure’s foundation. The drilling method chosen depends on the project’s requirements, including the type of soil or rock, the desired depth, and the diameter of the hole. Large drill rigs are used to bore down to a stable layer, such as bedrock, to ensure the building’s load is properly transferred and supported.

The specific steps and equipment vary based on the method employed.

Common Foundation Drilling Methods

- Continuous Flight Auger (CFA) Drilling: An auger with a continuous helical blade drills into the ground, and as it’s withdrawn, concrete is pumped through the hollow stem to form the pile. This is a single-pass method that saves time.

- Kelly Drilling: This is a rotary drilling method that uses a telescoping Kelly bar to reach great depths. It uses various tools like augers and buckets to remove soil, and the hole is then reinforced with a steel cage and filled with concrete.

- Down-the-Hole (DTH) Drilling: Used for very hard rock and boulders, this method utilizes a pneumatic hammer at the end of the drill string. Compressed air powers the hammer to break up the rock, while also clearing the cuttings from the hole.

- Grab Drilling: An older method that uses a crane with a claw-like tool to repeatedly grab and remove soil or rock from a cased hole. This process is repeated until the required depth is achieved.

Drill Bits for Foundation Drilling

Recommended Drill Bits for Foundation Drilling

In foundation drilling, the drill bit is the most critical tool, as its design and material determine its effectiveness in various ground conditions, from soft soil to hard rock. Unlike smaller household drill bits, these are robust, heavy-duty tools engineered to handle immense force and torque.

The selection of the correct bit is essential for achieving the required penetration rate, maintaining hole stability, and ensuring the overall success of the project. Specialized drill bits are tailored for specific drilling methods and geological formations.

- Continuous Flight Auger (CFA) Bits: These bits feature a continuous helical screw that not only drills the hole but also simultaneously brings soil cuttings to the surface, making them highly efficient for drilling in soft to medium-dense soils and clays.

- Core Barrel Bits: Used to extract a cylindrical core of rock or soil, these bits are ideal for geotechnical investigations where an undisturbed sample is needed to analyze the ground composition and properties.

- Down-the-Hole (DTH) Hammer Bits: These are used with a pneumatic hammer at the end of the drill string. They have tungsten carbide inserts that percussively break hard rock formations, making them extremely effective for drilling in granite, limestone, and other abrasive materials.

- Tricone Bits: Featuring three rotating cones with cutting teeth or inserts, these bits break rock through a crushing and shearing action. They are highly versatile and widely used in both rotary and percussive drilling for a range of rock hardnesses.

- Rock and Soil Auger Bits: A wide variety of auger bits with different cutting teeth (e.g., carbide-tipped) are used for drilling through a range of materials, from soft, cohesive soils to mixed ground with gravel and even boulders.

Drill Bit for Concrete Foundation

Selecting the correct drill bit for a concrete foundation is crucial, as the material presents a significant challenge requiring specialized tools for efficient ground and rock drilling. The hardness of the material, which can include aggregate and rebar, demands robust bits paired with a powerful hammer or rotary hammer drill.

- SDS-Plus and SDS-Max Rotary Hammer Bits These drill bits are designed for maximum efficiency in concrete and hard rock. The SDS shank system prevents slippage and is specifically made to handle the high-impact energy of a rotary hammer, allowing for faster penetration and deeper ground drilling operations on tough foundation materials.

- Carbide-Tipped Masonry Bits Featuring extremely durable tungsten carbide tips, these bits are ideal for general concrete, stone, and brick drilling. They maintain their sharp cutting edges and withstand the intense heat and abrasion generated by hammer drills, making them a common choice for smaller foundation anchor holes.

- Diamond Core Drill Bits Used for cutting very large diameter, precise holes in reinforced concrete and exceptionally hard rock. These bits feature diamond-coated cutting edges that are highly effective for core sampling or for creating major pass-throughs in a concrete foundation, often requiring wet-drilling.

- Four-Cutter Head Bits These bits have a reinforced four-cutter design, offering superior strength when encountering rebar within a concrete foundation. They are less likely to get stuck or shatter compared to two-cutter bits, providing a safer and more continuous drilling operation for foundation and ground work.

Drill Rods for Foundation Drilling

Recommended Drill Rods for Foundation Drilling

Drill rods, often called drill pipes, are the cylindrical steel tubes that form the drill string in foundation drilling. They are the essential link between the drill rig on the surface and the cutting bit at the bottom of the hole. Their primary function is to transmit rotational torque and, in some cases, high-frequency impact energy from the rig’s power source to the drill bit, enabling it to break up soil and rock.

Because they must withstand immense torsional, compressive, and tensile stresses, these rods are typically made from high-quality, heat-treated alloy steel to ensure durability and prevent failure during deep drilling operations.

- Continuous Flight Auger (CFA) Rods: These are hollow, tubular rods with a continuous spiral flighting welded to the exterior. They are used in CFA drilling to remove soil cuttings from the hole while simultaneously allowing grout or concrete to be pumped down through their center.

- Kelly Bars: Used in Kelly drilling, these are telescoping, square or hexagonal rods that extend and retract to increase the drilling depth. They transfer the rotation from the rig’s rotary table to the drill bit at the bottom of the hole.

- Down-the-Hole (DTH) Drill Rods: Unlike other rods that transmit both rotation and impact, DTH rods are specifically designed to transmit torque and air pressure to a hammer located at the bottom of the borehole. They do not transmit percussive energy.

- Coring Rods: These are specialized rods used in geotechnical exploration and sampling. They work in conjunction with a core barrel to retrieve an intact cylindrical sample of rock or soil from the ground for analysis.

What Are the Different Types of Foundation Drilling?

Foundation drilling encompasses several specialized methods, each suited to different geological conditions and project requirements. The goal is always to create a stable foundation, but the approach changes based on the type of soil or rock.

Rotary Drilling

This is a versatile method that uses a rotary drill bit to bore through the ground. It’s excellent for creating large-diameter holes for foundations.

- Kelly Drilling: This is a classic rotary method that uses a telescopic Kelly bar to transfer torque from the rig to the drilling tool. It’s highly adaptable and can be used in almost all soil types, including rock.

- Continuous Flight Auger (CFA) Drilling: This single-pass method uses a long, helical auger to drill and remove soil cuttings. Once the required depth is reached, concrete is pumped through the hollow stem of the auger as it’s withdrawn, forming a cast-in-place pile. This method is fast, quiet, and doesn’t produce vibrations, making it ideal for urban areas.

Percussive Drilling

This method uses a hammering action to break up hard rock and boulders. It’s the go-to solution for challenging ground conditions where rotary methods are inefficient.

- Down-the-Hole (DTH) Drilling: A pneumatic hammer, located directly behind the drill bit at the bottom of the hole, strikes the bit at high frequency. Compressed air powers the hammer and simultaneously flushes rock cuttings to the surface, making it extremely effective for penetrating hard rock formations.

- Micropiling: This technique involves drilling small-diameter piles (typically 3-10 inches). While it can use rotary or percussion methods, it’s often combined with a simultaneous casing system to stabilize the borehole. Micropiles are used for underpinning existing structures, slope stabilization, and in areas with limited access.

Conclusion

In conclusion, foundation drilling is an indispensable process that forms the bedrock of modern construction. By creating secure connections to stable soil or rock layers, it ensures the long-term integrity and safety of heavy structures worldwide. The methods and equipment used are continuously advancing, allowing engineers to tackle increasingly complex projects and ground conditions with greater precision and efficiency.

The success of any foundation drilling project hinges on the quality of its tools. High-performance drilling bits, rods, and anchors are essential for achieving optimal penetration and stability. Using reliable, durable equipment is not just a choice—it’s a necessity for ensuring that your foundational work is solid and dependable for decades to come.

For all your project needs, consider sourcing your wholesale foundation drilling tools from us. Sinodrills provides a comprehensive range of high-quality, professional-grade equipment engineered for superior performance and durability. Trust our expertise to supply the tools that will help you build with confidence and precision.