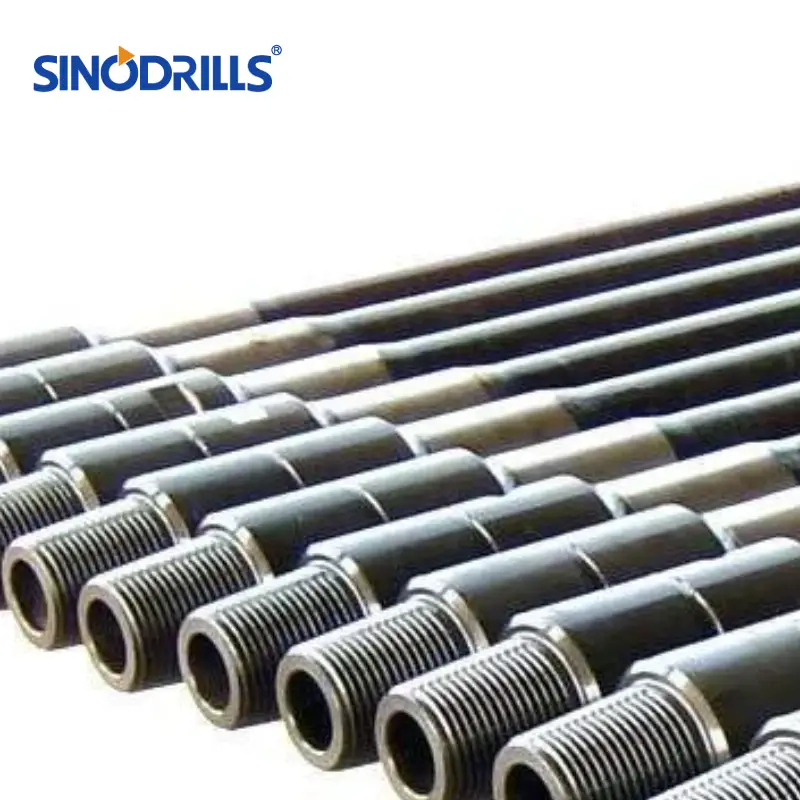

Custom Friction Welded Drill Pipe Manufacturer in China

We offer friction-welded drill pipe, meticulously engineered for superior performance in diverse drilling applications. Our pipes feature robust connections, enhanced strength, and exceptional durability, ensuring reliable power transfer and extended lifespan in demanding environments. Ideal for DTH and other drilling methods, they deliver consistent results and excellent value.

Sinodrills - Your Trusted Friction Welded Drill Pipe Manufacturer from China

Sinodrills stands as your trusted friction-welded drill pipe manufacturer & factory in China. Leveraging advanced technology and stringent quality control, we produce durable DTH drill rods designed for optimal performance in various drilling applications. Our commitment to excellence ensures reliable products that maximize efficiency and reduce downtime for drillers worldwide.

Various Friction Welded Drill Pipe

mild steel seamless friction welded drill pipe

We offer mild steel seamless friction-welded drill pipe, engineered for exceptional strength and longevity. Our seamless pipe bodies ensure uniform thickness and superior pressure resistance, while the friction-welded tool joints provide a robust, high-integrity connection. These pipes are ideal for various drilling applications, delivering reliable performance and enhanced operational efficiency.

carbon steel friction welded drill pipes

We offer robust carbon steel friction-welded drill pipes, providing exceptional strength and durability for diverse drilling operations. These pipes ensure superior power transfer and resistance to wear, making them highly effective for demanding DTH applications in mining, construction, and water well drilling. Our carbon steel pipes deliver a cost-effective and reliable solution for your project needs.

carbon steel friction welded drill pipes

We offer premium alloy steel friction-welded drill pipes, renowned for exceptional strength and wear resistance in challenging drilling environments. Our pipes utilize high-grade alloy steel, combined with precise friction welding, to ensure a robust and durable connection between the pipe body and tool joint. This results in superior performance, extended operational life, and reduced maintenance for your drilling projects.

hdd friction welded type drill pipe

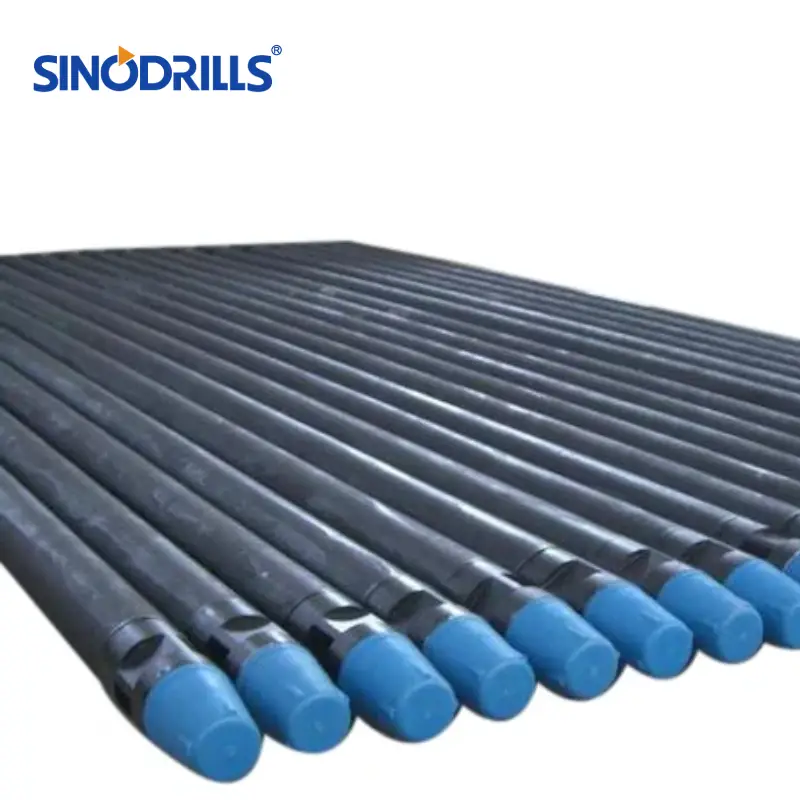

We offer premium HDD (Horizontal Directional Drilling) friction-welded drill pipe, specifically designed for the demanding requirements of trenchless technology. Our pipes boast exceptional strength, flexibility, and wear resistance, crucial for navigating complex underground formations. Engineered for optimal power transfer and extended service life, they ensure efficient and reliable operations in various HDD projects.

DTH friction welding drill pipe in water well drilling

We offer premium DTH friction-welded drill pipe specifically designed for water well drilling. Our pipes boast exceptional strength, durability, and precise connections, ensuring efficient power transfer and extended service life. Manufactured with rigorous quality control, these drill pipes deliver reliable performance, even in challenging geological conditions, making them ideal for all your water well projects.

custom length DTH friction welded drill pipe

We specialize in custom length DTH friction-welded drill pipe, tailored to your specific project needs. Our manufacturing ensures precise lengths, combined with the superior strength and durability of friction welding. This offers optimized drilling efficiency and reduced waste, providing a perfect fit for diverse geological conditions and rig requirements.

Customize Your Desired Friction Welded Drill Pipe

Superior Weld Integrity

We ensure that each friction-welded joint possesses exceptional integrity. This means the metallurgical bond between the pipe body and tool joint is incredibly strong, often exceeding the strength of the base material. Our process virtually eliminates defects, crucial for withstanding intense drilling forces.

Optimized Performance in Demanding Conditions

We design our friction-welded drill pipes to excel in the most challenging drilling environments. The robust construction and seamless power transfer minimize energy loss, leading to faster penetration rates and prolonged service life even in abrasive formations or under high-stress applications.

Reduced Risk of Failure and Downtime

We understand that equipment failure means costly downtime. Our friction welding process significantly reduces the risk of joint failure, fatigue cracking, and premature wear, translating into more operational hours for your drilling projects and lower overall maintenance costs.

Customization and Versatility

We offer friction-welded drill pipes in various specifications, including custom lengths, to meet your unique project requirements. This versatility allows our pipes to be seamlessly integrated into diverse drilling rigs and adapted for different geological conditions, ensuring maximum efficiency for your operations.

what is friction welding?

Friction welding is a solid-state joining process that creates a high-integrity bond between two materials without melting them. It operates by bringing two workpieces into contact under pressure while one is rotated or oscillated at high speed.

The mechanical friction between the surfaces generates intense heat, causing the material at the interface to soften and reach a plastic state. As the relative motion ceases, a significant axial force is applied, forging the plasticized material together and expelling any impurities, which results in a strong, metallurgical bond at the atomic level.

This method is highly effective for joining both similar and dissimilar materials, producing welds with excellent mechanical properties and a minimal heat-affected zone.

How Does Friction Welding Work?

Friction welding is a unique solid-state joining method that relies on mechanical friction to generate the heat necessary for bonding two components, without reaching their melting point. The process typically involves:

Relative Motion: One workpiece is rapidly rotated or oscillated, while the other is held stationary.

Applied Pressure: The two workpieces are brought into contact under significant axial force. This contact, combined with the relative motion, generates intense frictional heat at the interface.

Plasticization: The generated heat softens the material at the faying surfaces, bringing it to a plastic, malleable state just below its melting point.

Forging: As the material plasticizes, the relative motion is stopped. Simultaneously, the axial force is typically increased, forging the softened materials together. This action expels impurities and consolidates the bond at a molecular level, resulting in a strong, defect-free weld.

advantages of friction stir welding

Friction stir welding (FSW) offers a compelling set of advantages, particularly for materials difficult to join with traditional fusion welding methods. As a solid-state process, it avoids melting the material, leading to superior metallurgical properties in the weld zone.

This technique is highly valued across various industries for its ability to produce high-quality, durable joints.

Superior Weld Quality: FSW produces fine-grained microstructures and eliminates common fusion welding defects like porosity, solidification cracking, and hot cracking, resulting in welds with excellent mechanical properties, including high tensile and fatigue strength.

Joins Dissimilar Materials: One of FSW’s most significant benefits is its capability to weld dissimilar materials, such as aluminum to steel, which are challenging or impossible to join effectively with conventional welding techniques. This expands design possibilities and material combinations.

Minimal Distortion and Residual Stress: Since FSW operates below the melting point, it significantly reduces thermal distortion, shrinkage, and residual stresses in the welded components, leading to greater dimensional accuracy and less need for post-weld straightening.

Environmentally Friendly and Safer: FSW is a clean process, producing no fumes, smoke, spatter, or radiation. It doesn’t require filler metals or shielding gases, making it more environmentally friendly, safer for operators, and reducing consumable costs.

Energy Efficient: Compared to fusion welding, FSW generally requires less energy input, as it doesn’t need to melt the base materials. This contributes to lower operating costs and a reduced carbon footprint.

where to use Friction Welded Drill Pipes

Friction welded drill pipes are primarily used in applications demanding extreme strength, durability, and reliable power transmission under harsh conditions. Their superior metallurgical bond makes them ideal for environments where traditional welds might fail, ensuring operational efficiency and safety.

Oil and Gas Drilling: These pipes are extensively used in oil and gas exploration and production for both conventional and directional drilling. The high torque and axial loads involved necessitate the strong, defect-free welds that friction welding provides.

Mining Operations: In various mining contexts, including underground and surface mining, friction welded drill pipes are employed for blast hole drilling, exploration, and rock reinforcement, where robust tools are essential to penetrate tough rock formations.

Water Well Drilling: For drilling water wells, especially in challenging geological strata, the reliability and long lifespan of friction welded pipes are crucial. They ensure efficient progress and reduce the need for frequent replacements.

Geotechnical and Construction Projects: These pipes find application in geotechnical investigations, piling, and foundation drilling for large construction projects. Their ability to withstand high stress and repeated use makes them suitable for demanding ground engineering tasks.

how to choose Friction Welded Drill Pipes?

Choosing the right friction-welded drill pipe is crucial for optimizing drilling efficiency, ensuring safety, and maximizing return on investment. Several key factors must be carefully considered to select the best pipe for your specific operational needs and geological conditions.

Drilling Depth and Conditions: The depth of your drilling project significantly impacts the required strength and grade of the drill pipe. Deeper wells and complex geological formations demand higher strength steel grades (e.g., G105, S135) to withstand increased pressure, tension, and torsional stress.

Pipe Dimensions (OD, Wall Thickness, Length): Selecting the appropriate outer diameter (OD), wall thickness, and length is vital for compatibility with your drilling rig and downhole tools. These dimensions affect the pipe’s weight, stiffness, and fluid circulation capacity, directly influencing drilling performance.

Tool Joint and Thread Type: The type of tool joint and thread connection (e.g., API Reg, FH, IF, NC) must match your existing drill string components to ensure secure and efficient make-up and break-out. The joint’s design also impacts its torsional strength and longevity.

Material Grade and Heat Treatment: The specific steel grade of the pipe body and tool joint, along with any post-weld heat treatment, dictates the pipe’s mechanical properties, including yield strength, tensile strength, and hardness. These properties are critical for resisting wear, fatigue, and corrosion in various drilling environments.

Send Your Inquiry Now

All-in-one Friction Welded Drill Pipe Solutions for Your Project

At Sinodrills, we empower you to customize your desired friction-welded drill pipe to perfectly match your specific drilling requirements. Choose from various lengths, diameters, and thread connections, ensuring optimal compatibility with your existing rig and geological conditions. Our tailored solutions guarantee enhanced efficiency, reduced operational costs, and superior performance for your unique projects.