Custom Full Bridge Coupling Sleeve Manufacturer in China

We offer high-performance full-bridge coupling sleeves, engineered with continuous internal threading for maximum stability and superior energy transfer in the harshest percussive drilling environments. Manufactured from premium, heat-treated steel, we ensure unmatched durability, preventing thread failure and significantly extending the lifespan of your drill string in hard rock and deep-hole applications.

Sinodrills - Your Trusted Full Bridge Coupling Sleeve Manufacturer from China

From our specialized facilities, this manufacturer provides precision-engineered, continuously threaded sleeves. Built from premium-grade alloy steel and heat-treated for resilience, these components are designed to deliver maximum impact energy transfer and exceptional tool longevity. They ensure stable, tight connections for demanding top-hammer applications in mining, tunneling, and construction across the globe.

Full Bridge Coupling Sleeve Features

Continuous Internal Threading: The threads run the entire length, allowing the drill rods to be screwed in until they butt end-to-end. This feature ensures the tightest possible joint rigidity.

Eliminates Thread Creep: Full thread engagement positively locks the joint, preventing the coupling from loosening or creeping along the thread during severe vibration or heavy percussive loads.

Maximum Energy Transfer: The solid, metal-to-metal butt contact at the rod ends minimizes energy loss in the drill string. This boosts the efficiency of the percussive impact delivered to the bit.

Reduced Jamming Potential: This connection design maintains tighter joints even after extensive use in abrasive conditions. A firmer connection reduces the chance of rods jamming during drilling.

Independent Rotation Suitability: They are best suited for machines with independent rotation where the coupling must not move axially along the joint threads, ensuring consistent operation.

Full Bridge Coupling Sleeve Benefits

Continuous Internal Threading: The sleeve features threading across its entire inner length, allowing rod ends to butt together tightly. This complete engagement minimizes energy loss and maximizes impact transmission efficiency.

Eliminates Thread Creeping: Its design positively prevents the coupling from creeping or loosening along the thread joints during heavy percussive drilling. This maintains joint tightness and reduces the risk of tool failure.

Superior Uncoupling Characteristics: Full-bridge couplings are known for their easier and better uncoupling performance, especially when compared to semi-bridge types. This reduces downtime and speeds up rod changes.

Best for Independent Rotation: This type is particularly well-suited for drill rigs that use an independent rotation function. The design minimizes jamming and ensures a consistent connection.

Heavy-Duty Surface Applications: Typically used in demanding open-pit or surface mining, their robust, continuous connection handles intense forces in hard rock and deep-hole drilling conditions exceptionally well.

Full Bridge Coupling Sleeve Applications

Surface Mining & Quarrying: Used for bench drilling and production holes in open-pit sites, providing maximum joint rigidity to prevent loosening in high-vibration environments.

Independent Rotation Drills: Best suited for drilling machines with independent rotation, as the full threading positively eliminates any potential for the coupling to creep along the joint.

Heavy-Duty Percussive: Essential for hard, abrasive rock formations to ensure robust, shock-resistant connections that maintain optimal energy transfer from the shank to the drill bit.

Deep Hole Extension: Utilized when joining multiple drill rods in deep-hole applications to maintain string alignment and integrity, reducing the risk of jamming or tool failure.

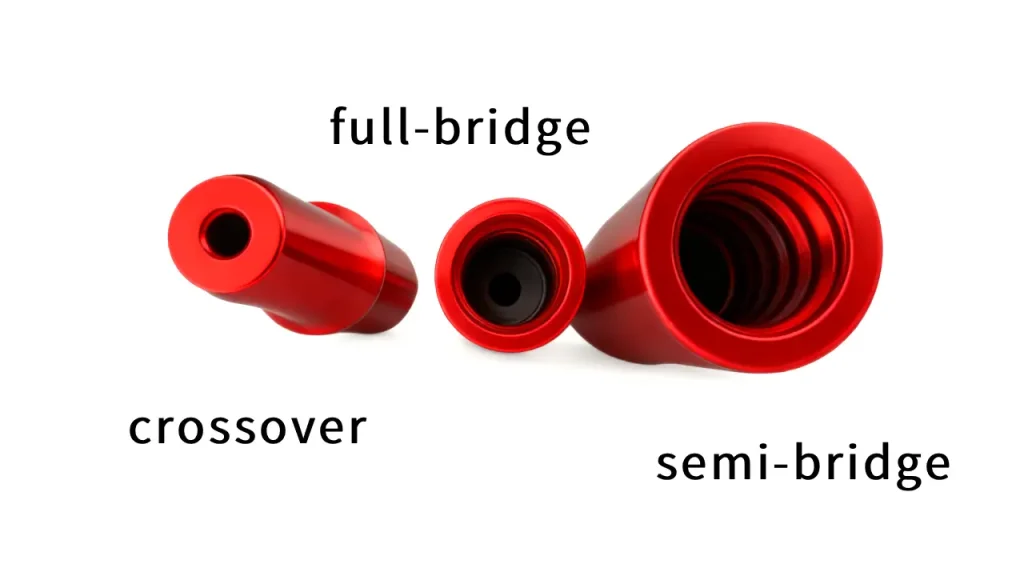

Full Bridge Coupling Sleeve and Semi Bridge

Full Bridge Coupling Sleeves

Full Bridge couplings feature continuous internal threading throughout their entire length, allowing the ends of the drill rods to meet securely in the center.

Design & Stability: This continuous thread design positively eliminates the potential for thread creep, creating a highly rigid, unyielding connection. This rigidity ensures maximal energy transfer and extends the life of the drill string components.

Application: Primarily used in demanding surface drilling applications, especially with rock drills featuring independent rotation. They offer superior uncoupling characteristics and maintain tighter joints, reducing the risk of jamming in heavy-duty use.

Semi Bridge Coupling Sleeves

Semi Bridge couplings, the most common type, have threads at both ends but incorporate a small, unthreaded “bridge” section in the middle.

Design & Convenience: The central bridge acts as a positive stop, ensuring the rod ends butt precisely together for efficient energy transfer. This design allows for easier and quicker make-up and break-out of the drill string, improving operational efficiency.

Application: Best suited for high-torque drilling rigs in general operations, including underground mining and tunneling. The semi-bridge provides a robust connection while offering a better balance between connection strength and field assembly convenience.

Customize Your Desired Full Bridge Coupling Sleeve

Custom Thread Specifications

We customize both the thread size (like T45 or T51) and thread type to seamlessly interface with your existing drill rods and shank adapter. This precision engineering guarantees full thread engagement, which is vital for maximizing impact energy transmission and eliminating joint play.

Material Selection and Heat Treatment

We use specialized alloy steel grades chosen specifically for the high stress and percussive shock of hard rock drilling. Our proprietary heat treatment process is fine-tuned to achieve the optimal balance of surface hardness (for wear resistance) and core toughness (to prevent breakage).

Dimensional Adjustments (Length/Diameter)

We can adjust the sleeve length and outer diameter to optimize flushing and clearance within your drill hole. Custom lengths ensure the proper spacing and butt-contact between drill rods, enhancing structural integrity and reducing the likelihood of tool jamming.

Surface and Anti-Corrosion Finish

We apply specialized surface treatments, such as passivation or protective coatings, to enhance resistance against drilling muds and corrosive underground water. These finishes are essential for maintaining thread integrity and tool life in highly aggressive or wet mining conditions.

All-in-one Full Bridge Coupling Sleeve Solutions for Your Project

Maximize productivity in demanding projects with our Full Bridge Coupling Sleeves. Their continuous thread design eliminates joint play and creep, ensuring a secure, rigid drill string for superior energy transfer and penetration, particularly in hard rock mining and surface applications. This stability reduces tool wear and prevents jamming, making them ideal for high-impact, independent rotation drill rigs.