Custom HDD PDC Bit Manufacturer in China

HDD PDC bits are at the forefront of horizontal directional drilling technology, offering unparalleled performance and efficiency for modern infrastructure projects. These specialized drill bits, featuring Polycrystalline Diamond Compact cutters, are engineered to deliver faster penetration rates, superior steering capabilities, and extended tool life in a wide array of challenging ground conditions. From soft clays to abrasive shales and even consolidated rock, our HDD PDC bits provide the cutting power and durability needed to optimize your drilling operations, reduce downtime, and ultimately, lower project costs. Discover how these advanced bits are transforming the landscape of underground utility installation and pipeline construction.

Sinodrills - Your Trusted HDD PDC Bit Manufacturer from China

As a premier supplier, we understand the critical role HDD PDC bits play in modern horizontal directional drilling. These specialized bits, featuring Polycrystalline Diamond Compact cutters, offer unparalleled efficiency and durability in diverse ground conditions. Unlike traditional roller cones, HDD PDC bits provide faster penetration rates, reduced torque, and superior steerability, leading to significant time and cost savings on your projects. Their robust, fixed-cutter design minimizes vibration and extends tool life, even in challenging formations. We ensure our HDD PDC bits are engineered for optimal performance, helping you achieve straighter bores, larger holes with smaller rigs, and a seamless drilling experience. Partner with us for the cutting-edge technology your HDD operations demand.

Various HDD PDC Bit

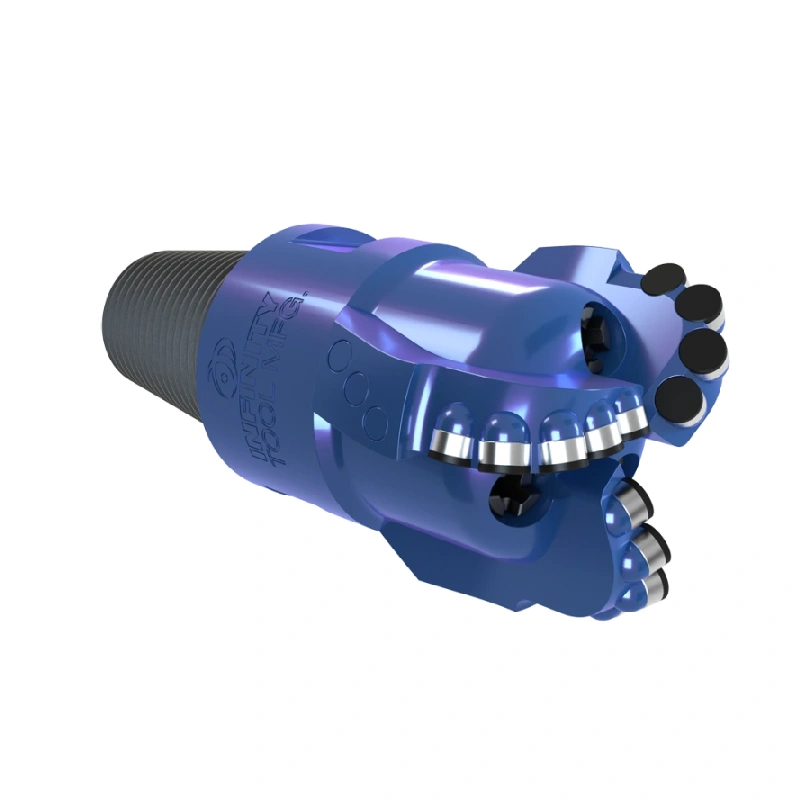

custom Standard Duty HDD PDC Bits for Versatile Performance

Our standard duty HDD PDC bits are designed for reliable and efficient performance in a wide range of common ground conditions, including compacted soils, clays, and softer shales. These bits feature a robust body and strategically placed PDC cutters, offering an excellent balance of penetration rate and durability for everyday horizontal directional drilling tasks. They are a cost-effective solution for projects where extreme rock hardness is not anticipated, providing consistent results and minimizing wear on your drilling equipment. Trust our standard duty HDD PDC bits to deliver dependable performance on your versatile drilling applications.

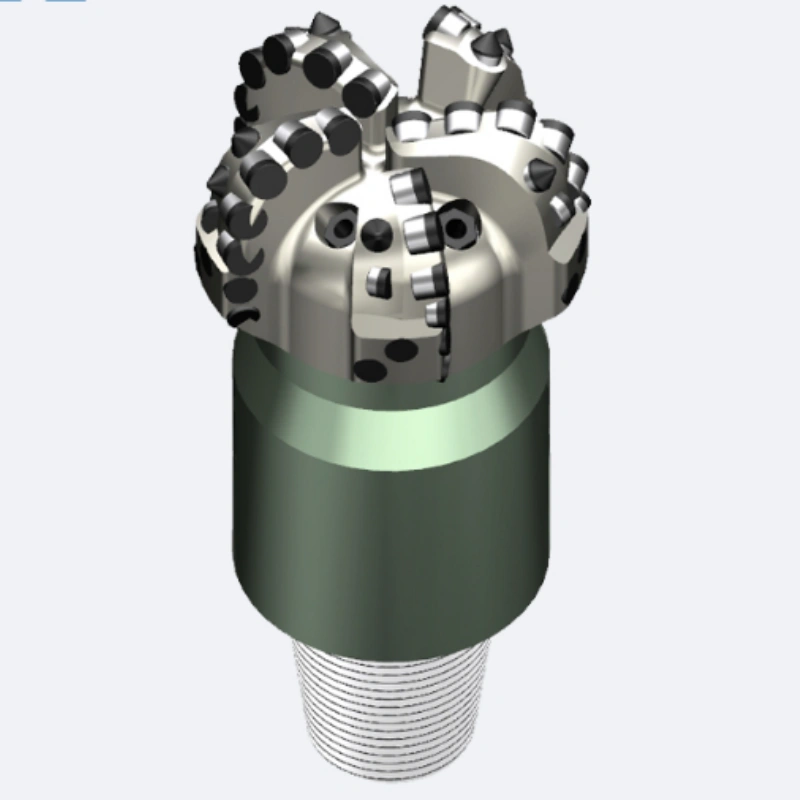

Heavy Duty HDD PDC Bits for Challenging Formations

For more abrasive or consolidated ground conditions, our heavy-duty HDD PDC bits are engineered to withstand extreme wear and deliver aggressive cutting action. These bits incorporate more resilient PDC cutters, often larger in size or with enhanced diamond volume, and feature a reinforced bit body to handle increased torque and impact. They excel in formations such as hard shales, sandstone, and mixed ground, offering superior longevity and maintaining high penetration rates where standard bits might struggle.

Rock-Specific HDD PDC Bits for Ultimate Hard Rock Drilling

When facing the toughest rock formations in horizontal directional drilling, our rock-specific HDD PDC bits are your ultimate solution. These specialized bits are meticulously designed with unique cutter layouts, highly durable PDC materials, and often incorporate carbide inserts to maximize cutting efficiency and extend bit life in consolidated rock. They are optimized to break through hard limestone, granite, and basalt with impressive speed and precision.

5 Range HDD PDC Bit

These 5-inch range HDD (Horizontal Directional Drilling) PDC (Polycrystalline Diamond Compact) drill bits are workhorses for a variety of medium to large-scale construction projects. Engineered for efficiency and durability, they excel in challenging ground conditions, including compacted soils, soft rock formations, and even some fractured rock. Their robust PDC cutters provide superior penetration rates and extended tool life, minimizing downtime and increasing productivity on jobs such as pipeline installations, utility crossings, and general infrastructure development. The larger size allows for greater steerability and stability in wider bores.

1 to 3 Range HDD PDC Bit

Designed for precision and maneuverability, the 1-inch to 3-inch range HDD PDC drill bits are ideal for smaller, more intricate directional drilling applications. These compact bits are essential for navigating tight spaces, sensitive urban environments, and projects requiring minimal surface disturbance. They are commonly used for fiber optic installations, residential utility hook-ups, and other confined area drilling. Despite their smaller size, they incorporate the same high-performance PDC cutters, ensuring efficient drilling through various soil types and soft rock, delivering clean, accurate pilot holes.

HDD PDC Bit PDC Pilot Bit

The HDD PDC pilot bit is the crucial vanguard of any directional drilling operation. Specifically designed to initiate the bore, these bits create the initial pilot hole that guides the subsequent reaming process. Equipped with strategically placed PDC cutters, they offer exceptional steering capabilities and high penetration rates in diverse ground conditions. Their robust construction ensures they can withstand the initial impacts and abrasive forces encountered at the start of a bore. The pilot bit’s performance directly impacts the accuracy and efficiency of the entire drilling path, making its design paramount.

Directional Diamond HDD PDC Bits

Directional diamond HDD PDC bits represent the pinnacle of drilling technology for challenging formations. These bits combine the cutting efficiency of PDC cutters with the extreme hardness and abrasion resistance of natural or synthetic diamonds. This hybrid design allows them to excel in highly abrasive ground, hard rock, and interbedded formations where conventional PDC bits might struggle. Their enhanced durability and cutting performance lead to extended bit life and reduced trips, making them cost-effective for complex, long-distance bores and projects encountering exceptionally tough geological conditions, ensuring precise directional control.

HDD Drilling and Deep Groundwater Well PDC Drill Bits

PDC drill bits are indispensable for HDD drilling in deep groundwater well construction due to their superior performance in varied geological strata. These bits are engineered to penetrate consolidated rock, unconsolidated sediments, and interbedded layers often encountered when drilling for water resources. Their high ROP (Rate of Penetration) and extended wear life minimize drilling time and costs, crucial for deep well projects. The robust design and efficient cutting action of PDC bits ensure a clean, stable bore for casing installation, vital for ensuring the integrity and longevity of the groundwater well.

Customize Your Desired HDD PDC Bit

Enhanced Penetration Rates with Our HDD PDC Bits

When time is money, the speed at which you drill directly impacts your project’s profitability. Our HDD PDC bits are engineered with advanced cutter geometries and strategic diamond placement to maximize the rate of penetration (ROP). This means less time spent drilling, allowing your crews to complete projects faster and move on to the next job sooner. The continuous cutting action of PDC (Polycrystalline Diamond Compact) cutters minimizes the need for frequent bit changes, reducing non-productive time and streamlining your overall drilling operation. Experience a significant boost in drilling speed with our high-performance HDD PDC bits.

Superior Durability and Longevity of Our HDD PDC Bits

In the demanding environment of horizontal directional drilling, bit durability is paramount. Our HDD PDC bits are constructed with premium materials and undergo rigorous quality control to ensure exceptional resistance to wear and abrasion. The robust fixed-cutter design eliminates moving parts, significantly reducing the risk of mechanical failure compared to traditional roller cone bits. This extended lifespan translates into fewer bit trips, saving you valuable time and labor costs. Invest in the long-term reliability of your drilling operations with our durable HDD PDC bits, designed to withstand the toughest ground conditions.

Optimized Steerability with Precision-Engineered HDD PDC Bits

Accurate steering is crucial for navigating complex underground pathways in HDD. Our HDD PDC bits are engineered for superior steerability, allowing operators to maintain precise control over the bore path. The fixed-cutter design provides consistent face contact with the formation, facilitating smooth transitions and accurate trajectory adjustments. This precision helps prevent costly deviations, reduces the need for re-drilling sections, and ensures your pipelines and utilities are installed exactly where they need to be. Achieve unparalleled directional control and precision with our expertly designed HDD PDC bits.

Cost Efficiency Through Our Advanced HDD PDC Bits

Choosing the right drill bit is a significant factor in controlling project costs. Our HDD PDC bits contribute to substantial cost savings through their combined benefits of faster ROP, extended lifespan, and superior steerability. Reduced drilling time means lower fuel consumption and labor costs. Fewer bit changes equate to less expense on replacement bits and less downtime. Minimized steering corrections lead to more efficient use of rig time. Ultimately, investing in our high-quality HDD PDC bits translates into a more profitable horizontal directional drilling operation for your business.

What is an HDD PDC bit?

HDD PDC bit is a specialized drill bit used in Horizontal Directional Drilling (HDD). It features Polycrystalline Diamond Compact (PDC) cutters, which are synthetic diamond layers bonded to a tungsten carbide substrate. These bits are designed for efficient and precise drilling in various geological formations encountered during trenchless installations.

These PDC cutters provide exceptional hardness and abrasion resistance, allowing the bit to effectively cut through rock and dense soils. This makes them ideal for creating pilot bores for pipelines, conduits, and cables without extensive excavation.

Send Your Inquiry Now

How do HDD PDC bits work?

HDD PDC bits work by rotating and scraping the formation using their fixed PDC cutters. Unlike roller cone bits that crush and grind, PDC bits shear the rock, leading to a smoother, more efficient cutting action.

The bit’s design, including its cutting structure and junk slot area, is optimized to remove cuttings efficiently and maintain high rates of penetration in various ground conditions.

Send Your Inquiry Now

What are the main advantages of using HDD PDC bits?

The main advantages of using HDD PDC bits include extremely fast penetration rates, especially in suitable formations like shale and limestone. They offer superior durability and longer bit life compared to other bit types, reducing the need for frequent bit changes.

Additionally, their fixed-cutter design provides smoother drilling with less vibration, which can lead to better borehole quality and reduced wear on drilling equipment.

Send Your Inquiry Now

What factors influence the lifespan of an HDD PDC bit?

Several factors influence the lifespan of an HDD PDC bit. These include the abrasiveness and hardness of the formation being drilled, the drilling parameters (e.g., rotational speed, weight on bit), and the effectiveness of the drilling fluid in cooling the bit and removing cuttings.

Proper bit selection for the specific geology, consistent monitoring during drilling, and avoiding excessive vibration also contribute significantly to extending the bit’s operational life.

Send Your Inquiry Now

All-in-one HDD PDC Bit Solutions for Your Project

We provide all-in-one taper drill rod solutions to simplify your drilling projects. Our extensive range offers high-quality rods suitable for various rock conditions and drilling machines, ensuring optimal performance and durability. From material selection to custom lengths and specialized coatings, we tailor solutions to meet your exact needs, maximizing productivity and reducing downtime for your specific application.