Rock drill bits are essential tools for any serious drilling project, but their cutting edges dull over time, leading to decreased efficiency and increased workload. Sharpening your bits not only restores their cutting power but also extends their lifespan, saving you money and the hassle of frequent replacements. This guide will walk you through the simple process of sharpening your rock drill bits to ensure they remain in peak condition.

Properly maintained drill bits are safer to use and perform better, penetrating rock faster and with less effort. Whether you’re a professional miner, a construction worker, or a DIY enthusiast, knowing how to sharpen your tools is a valuable skill. By following the steps outlined in this article, you can keep your bits in top shape, ensuring every drilling job is as efficient and smooth as possible.

What are Rock Drill Bits?

Rock drill bits are specialized cutting tools designed to break and penetrate hard rock formations. They are attached to the end of a drill rod on various drilling rigs, from handheld pneumatic drills to large-scale rotary machines used in mining and construction.

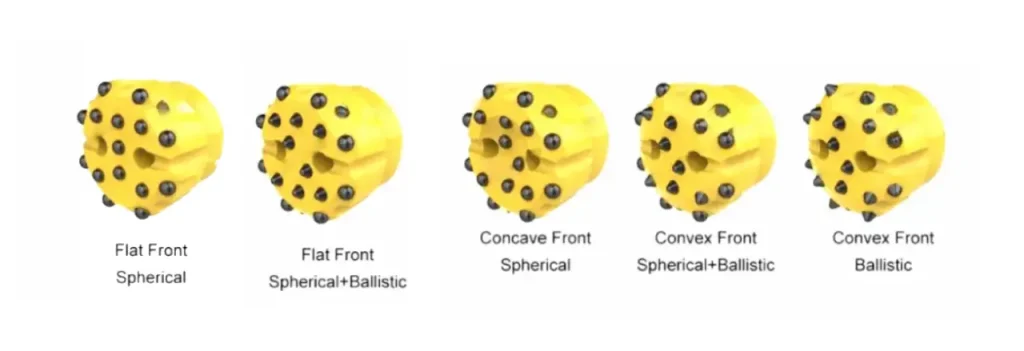

These rock drill bits are engineered with durable materials like tungsten carbide inserts or hardened steel teeth, and they come in a wide array of shapes and sizes to suit different rock hardnesses, abrasive conditions, and drilling objectives. Their primary function is to efficiently create boreholes for applications such as mineral exploration, quarrying, civil engineering projects, and well drilling. The selection of the right rock drill bit is crucial for optimizing performance, extending tool life, and ensuring safe and efficient drilling operations.

Why Do We Need Rock Drill Bit Sharpening?

Maintaining the sharpness of your rock drill bits is not just a good practice; it’s essential for efficient and effective drilling. As bits are used, their cutting edges become dull and worn, leading to a significant drop in performance. Sharpening them regularly addresses these issues, ensuring your drilling operations remain productive and safe.

- To Improve Drilling Efficiency: A sharp bit penetrates rock faster and with less effort. This reduces the time needed to complete a project, lowers fuel or energy consumption, and decreases the overall workload on your drilling equipment, extending its lifespan.

- To Reduce Operator Fatigue: When a bit is dull, the operator must apply more force and pressure to achieve the desired result. Sharpening the bit makes drilling easier, reducing physical strain on the operator and allowing for longer, more productive work sessions.

- To Prevent Tool Damage: A dull bit can cause excessive vibration and heat, which can lead to cracks or fractures in the bit itself and the drill rod. Sharpening prevents this stress, protecting your expensive drilling equipment from premature failure and costly repairs.

- To Enhance Safety: Worn-out bits are prone to binding or getting stuck in the borehole, which can be a safety hazard. A sharp, well-maintained bit drills smoothly and consistently, minimizing the risk of unexpected tool failure or accidents on the job site.

How to Sharpen Rock Drill Bits?

Sharpening rock drill bits requires a careful approach to restore their cutting power without causing damage. By following these steps, you can effectively recondition your bits, improving their performance and extending their operational lifespan for future drilling projects.

Step 1: Gather Your Tools

Before you begin the sharpening process, it is essential to gather all the necessary tools and safety equipment. The most critical tool is a grinder, which can be a bench grinder or a specialized pneumatic or electric bit sharpener. For rock drill bits, you must use a silicon carbide grinding wheel (green wheel) or a specific diamond cup wheel designed for grinding tungsten carbide. Using a standard aluminum oxide wheel (gray or white wheel) will not be effective and can damage the carbide buttons.

In addition to the grinder, you’ll need personal protective equipment (PPE).

- A face shield or safety glasses are non-negotiable to protect your eyes from sparks and metal fragments.

- Heavy-duty work gloves will protect your hands, and ear protection is recommended if you are using a loud grinder.

- A dust mask or respirator can also be beneficial to avoid inhaling fine grinding dust. Having all these items on hand ensures a safe and efficient sharpening process from start to finish.

Step 2: Inspect and Prepare the Bit

The second step is to thoroughly inspect and prepare the rock drill bit. Begin by closely examining the bit for any signs of major damage, such as large cracks in the steel body or severely chipped or missing carbide buttons. If the bit has extensive damage, it may be beyond repair and should be replaced. A bit with minor wear, however, is a perfect candidate for sharpening.

Next, you need to clean the bit thoroughly. Use a stiff brush or a wire brush to remove any dirt, mud, or rock dust that has built up during drilling. A clean bit allows you to clearly see the worn areas on the buttons and prevents debris from interfering with the grinding process. Once clean, securely mount the bit in a vice or a special bit holder. This provides stability and control, which is crucial for achieving an even and uniform grind without the risk of the bit slipping.

Step 3: Grind the Drill Bit Buttons

Now, you can begin the actual grinding process. Turn on your grinder and carefully bring the bit’s carbide buttons to the wheel. The goal is to remove the flattened areas and restore a rounded, domed shape. The key is to apply light, consistent pressure and use a smooth, controlled motion. Avoid pressing too hard, as this can generate excessive heat, which can damage the carbide inserts and even cause micro-fractures. It’s often better to make several light passes rather than one heavy pass.

As you grind, regularly check the shape of each button to ensure you are achieving a uniform dome. Pay close attention to the gauge buttons—the buttons on the outer edge of the bit—as these wear down the fastest. It is crucial to restore their full profile to ensure the bit drills a properly sized hole. Be careful to work on each button individually and avoid overheating any single spot. Taking your time and being meticulous during this step will yield the best results and restore your bit to a like-new condition.

Step 4: Check and Clean the Bit

After you have sharpened all the buttons, turn off the grinder and perform a final inspection of the bit.

- Carefully examine each carbide button to ensure that all the flats have been completely removed and a proper dome shape has been restored.

- Look for any new cracks or signs of overheating, such as a blue discoloration on the steel.

- The finished product should have a consistent and uniform profile across all the buttons.

Once you are satisfied with the sharpening job, give the bit one last cleaning to remove any grinding dust or small metal shavings. A quick wipe with a clean cloth or a blast of compressed air will do the trick. This final cleaning prepares the bit for storage or immediate use. A properly sharpened and cleaned bit is ready to perform at its best, ensuring optimal results, and a smooth, efficient drilling operation on your next project.

What Angle Are Drill Bits Sharpened?

The correct sharpening angle for rock drill bits is critical for maintaining optimal performance. Unlike general-purpose drill bits with a single point angle, rock drill bits are defined by the shape of their tungsten carbide buttons, which should be restored to a domed or spherical profile. The goal is to grind the flat spots that develop during drilling back to their original rounded shape, which provides the most effective cutting action. The specific angles involved are less about a single point and more about the overall geometry of the button’s face, but the general principle is to follow the bit’s original design.

- Dome Shape: The ideal profile for a sharpened rock drill bit button is a smooth, rounded dome. This shape is crucial for effective penetration and minimizes stress on the bit.

- Following the Drill Bit Manufacturer‘s Design: It’s best to maintain the bit’s original geometry. This means not trying to change the shape of the buttons, but simply restoring their original profile.

- No Single “Sharpening Angle”: Instead of a single angle like 118° or 135°, the process focuses on restoring the button’s dome, which provides multiple cutting surfaces for efficient rock crushing.

When to Sharpen Rock Drill Bits?

You can’t sharpen rock drill bits on a rigid schedule; it’s a process driven by the tool’s condition and performance. Recognizing the signs of a dull bit is crucial for maintaining drilling efficiency and preventing damage. Sharpening at the right time ensures you get the most out of your tools without compromising safety or productivity.

- When flats appear on the buttons: The most critical indicator is when the tungsten carbide buttons develop flat spots from contact with the rock. Experts recommend sharpening when these flats reach a certain size, typically about 1/3 to 1/4 of the button’s diameter, to maintain optimal drilling performance.

- When drilling speed slows down: A sharp bit will penetrate rock quickly and with minimal effort. If you notice a significant decrease in your drilling rate or feel you have to apply more pressure to get the bit to cut, it’s a clear sign that the cutting edges are no longer effective and need to be sharpened.

- When the drill produces excessive vibration: A dull bit doesn’t cut cleanly; instead, it tends to pound and scrape the rock. This can cause increased vibration, which not only fatigues the operator but also puts unnecessary stress on the drill rig and other components of the drill string, leading to premature wear and tear.

- When the bit shows signs of heat damage: Excessive friction from a dull bit generates heat, which can discolor the steel body or cause “heat checking” (small cracks) on the carbide inserts. Sharpening the bit before it reaches this point helps to prevent irreversible damage and extends the bit’s overall life.

Tips to Maintain Rock Drill Bits

Proper maintenance is crucial for extending the lifespan and ensuring the performance of your rock drill bits. By adopting a proactive approach to care, you can significantly reduce wear and tear, minimize the risk of tool failure, and save money on replacements. These simple tips will help you keep your bits in peak condition for every drilling job.

- Clean Bits After Each Use: Thoroughly clean your bits to remove all rock dust, mud, and debris. This prevents a buildup that can cause corrosion, interfere with sharpening, and hinder performance.

- Lubricate Properly: Ensure the drill rig and bits are properly lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction and heat, which are major causes of premature wear and damage to the bit’s body and carbide inserts.

- Use the Correct Drilling Technique: Avoid excessive pressure and rotation speed. Using the right drilling parameters for the specific rock type minimizes stress on the bit, preventing overheating and unnecessary wear on the cutting edges and gauge.

- Store Bits Correctly: Store your rock drill bits in a clean, dry environment, preferably in their original packaging or a protective case. This prevents damage from impacts and protects them from moisture, which can lead to rust and corrosion.

Conclusion

Keeping your rock drill bits sharp is a simple yet crucial task that yields significant benefits. By regularly sharpening your bits, you not only improve drilling efficiency and speed but also prolong the life of your tools. This practice saves you money in the long run by reducing the need for frequent replacements and ensures every drilling project is completed with precision and minimal effort.

Mastering the art of sharpening rock drill bits is a worthwhile skill for anyone in the drilling industry. It guarantees that your equipment operates at its best, enhancing safety and productivity on the job. A well-maintained bit drills cleaner holes, reduces strain on your machinery, and ultimately leads to a more successful and less strenuous operation.

To ensure your projects always run smoothly, invest in quality tools and learn to care for them properly. For all your drilling needs, we offer a wide selection of top-tier rock drill bits. Remember to check out our wholesale rock drill bits for durable and high-performing options that will serve you well for years to come.