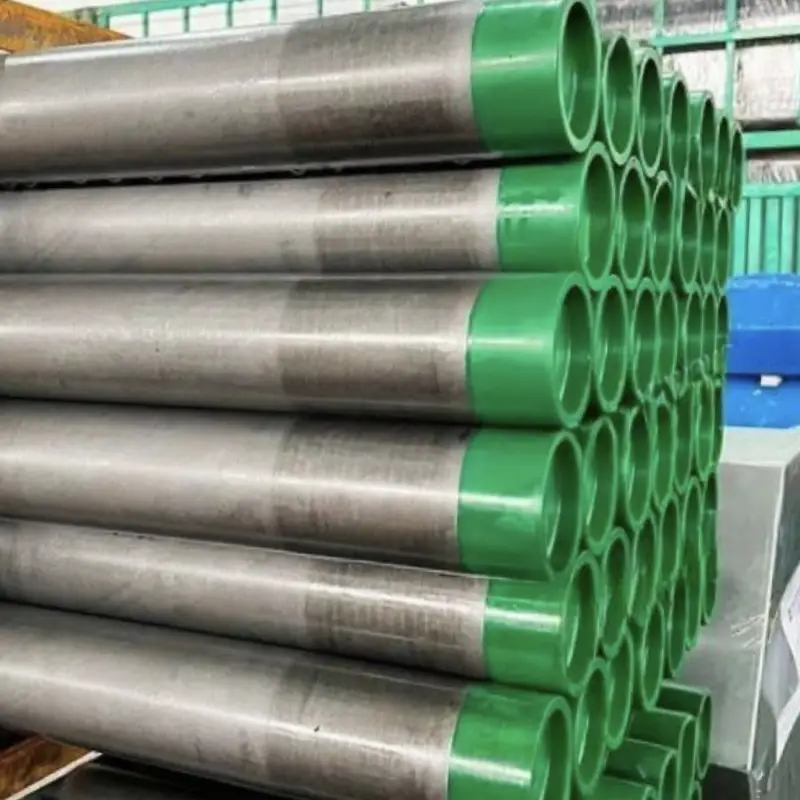

Custom HQ Drill Rod Manufacturer in China

We offer HQ drill rods, meticulously manufactured to DCDMA standards for wireline core drilling. Made from premium heat-treated alloy steel, our rods deliver exceptional strength, superior wear resistance, and long-lasting durability. They are engineered to provide maximum performance and reliable core recovery in a variety of geological conditions, ensuring efficiency for your mineral exploration projects.

Sinodrills - Your Trusted HQ Drill Rod Manufacturer from China

Sinodrills is your trusted manufacturer from China for premium HQ drill rods. We specialize in producing drilling tools that adhere strictly to DCDMA standards, using advanced heat-treated alloy steel. Our HQ rods are designed for wireline core drilling, offering exceptional strength and wear resistance to maximize core recovery and ensure reliable performance in the most demanding mineral exploration projects.

Your Leading HQ Drill Rod Manufacturer from China

As a leading HQ drill rod manufacturer from China, we deliver high-performance tools for core drilling. Our rods are meticulously crafted from premium heat-treated alloy steel, ensuring exceptional strength and durability. Engineered to DCDMA standards, they provide superior wear resistance and reliable performance in even the most challenging geological conditions, maximizing your core recovery and project efficiency.

HQ Drill Rod Benefits

- Superior Strength and Durability: Constructed from high-grade, heat-treated alloy steel, HQ rods are built to withstand the extreme stresses of deep drilling. They resist bending, buckling, and fatigue, ensuring a long service life in challenging rock formations.

- Enhanced Core Recovery: The larger diameter of HQ rods allows for a larger core sample compared to smaller rods like NQ or BQ. This results in better core recovery and a more representative sample of the geological formation, providing more accurate data for analysis.

- Optimized for Wireline Systems: Designed for use with wireline drilling systems, HQ rods enable the retrieval of core samples without the need to lift the entire drill string out of the borehole. This significantly reduces downtime and increases drilling efficiency.

- Efficient Fluid Flushing: The larger annulus created by the HQ rod size provides improved flushing capabilities. This allows for better removal of drill cuttings, which keeps the drill bit cool and clean, thereby increasing penetration rates and extending the lifespan of the bit.

Various HQ Drill Rod

HQ Wireline Drill Rods

Our HQ wireline drill rods are integral to wireline core drilling systems. They are designed with a specific internal diameter to allow the inner tube to be retrieved with a wireline overshot. This system dramatically increases efficiency by eliminating the need to pull the entire drill string out of the hole for each core sample.

wholesale HQ drill rods

We offer wide selection of wholesale HQ drill rods, manufactured from high-grade, heat-treated alloy steel. Designed to DCDMA standards, our rods deliver exceptional strength and wear resistance, ensuring efficient and reliable performance in wireline core drilling. Our competitive wholesale pricing makes it easy for you to stock up on the durable tools your mineral exploration projects demand.

HQ diamond drill rods

We offer HQ diamond drill rods, a key component for high-performance core drilling. Crafted from premium, heat-treated alloy steel, our rods are designed to work seamlessly with diamond drill bits to cut precise core samples. They deliver exceptional strength, durability, and wear resistance, ensuring reliable and efficient core recovery in the most challenging and abrasive geological formations.

customized HQ drill rods

We offer customized HQ drill rods to meet the unique needs of your specific drilling project. Our services include manufacturing rods in a variety of custom lengths, diameters, and specialized thread types. Using advanced heat treatment processes and premium alloy steel, we ensure your bespoke rods deliver the optimal balance of strength and durability for reliable performance.

Customize Your Desired HQ Drill Rod

Materials and Heat Treatment

We select specific steel alloys, like a premium chrome-moly steel, to achieve the ideal balance of strength and durability. Our precise heat treatment process, including controlled quenching and tempering, is meticulously calibrated to enhance the material’s toughness and resistance to fatigue.

Thread and Joint Design

We offer a variety of thread profiles, such as API standard or proprietary designs, to optimize connection integrity and ease of use. Our joint design can be customized to minimize stress concentration and maximize service life, ensuring a reliable connection even in the most demanding drilling conditions.

Length and Diameter

We can manufacture drill rods in a range of lengths, from a few feet to over 20 feet, allowing us to match the specific depth and rig requirements of your project. We also provide various diameter options, ensuring compatibility with your drilling tools and hole size.

Coatings and Surface Treatments

To extend the life of your drill rods, we can apply specialized coatings. Options like hard-chroming or nitriding significantly improve wear resistance and reduce friction, while certain anti-corrosion treatments are available for use in challenging environments with high salinity or acidity.

what is HQ in drill rod?

In the industry of drilling, “HQ” stands for a specific size and type of drill rod used in wireline core drilling. HQ originally meant “Hard Quarry,” which points to its suitability for drilling in hard geological formations, particularly in mineral exploration and geological sampling.

HQ drill rods are a part of a standardized system (which also includes sizes like BQ, NQ, and PQ) for retrieving high-quality core samples. HQ rods have a standard outside diameter of 88.9 mm (3.5 inches), making them compatible with HQ-sized core bits and other wireline components.

This system allows for the core sample to be retrieved from the inner tube without the need to pull the entire string of drill rods out of the borehole, which significantly improves drilling efficiency.

HQ drill rod applications

HQ drill rods are primarily utilized in wireline core drilling, a method widely used across several industries for retrieving undisturbed core samples from the earth. Their specific size and robust design make them ideal for a range of demanding applications where precision and durability are crucial. Key applications for HQ drill rods include:

Mineral Exploration: Used to drill deep into the earth to obtain rock core samples, which are analyzed to determine the location, grade, and quantity of mineral deposits.

Geotechnical and Geological Investigation: Essential for assessing subsurface conditions for major construction projects, such as foundations for buildings, dams, or bridges, by providing a detailed look at the rock and soil layers.

Environmental Research: Employed to collect soil and rock samples for environmental analysis, helping to monitor contamination levels or study geological processes.

Water Well Drilling: Used to create boreholes to access underground water sources, drilling through various layers of soil and rock to reach the desired aquifer.

How to Use HQ drill rods?

Using HQ drill rods is a precise process that requires careful execution to ensure a successful core drilling operation. The process involves several key stages, from preparing the site to retrieving the core sample.

Step 1: Site and Equipment Preparation

Before drilling begins, the site must be cleared and secured. The drill rig, power source, and water supply are set up and checked for proper function. This step also includes a thorough inspection of the HQ drill rods, core bits, and inner tube assembly to ensure all components are in excellent working order and free from damage.

Step 2: Assembling the Drill String

The core bit is threaded onto the bottom of the first HQ drill rod. The inner tube assembly, which will collect the core sample, is then inserted into the drill rod. This complete assembly, known as the drill string, is then carefully positioned over the borehole. Subsequent rods will be added as drilling progresses deeper into the ground.

Step 3: Drilling and Core Retrieval

The drill rig rotates the HQ drill string, applying downward pressure to advance the core bit into the ground. Water is pumped down the drill rod to cool the bit and flush cuttings to the surface. Once the desired drilling depth is reached, an overshot is lowered on a wireline to latch onto the inner tube, allowing the core sample to be brought to the surface without pulling the entire drill string.

Step 4: Core Sample Handling

After the core sample is retrieved, the inner tube is detached from the overshot and opened. The core is carefully extracted, logged, and placed into a core box. This process ensures the sample’s integrity is maintained, providing valuable geological data. The core boxes are then labeled with the correct depth interval and stored for further analysis.

Send Your Inquiry Now

All-in-one HQ Drill Rod Solutions for Your Project

We provide wholesale HQ drill rod solutions tailored to your project. Our rods are engineered with superior strength and durability, featuring precision-machined threads and optimal heat treatment for reliable performance in demanding conditions. We offer a variety of sizes and customizable options to ensure seamless integration and efficiency, minimizing downtime and maximizing your drilling success.