Custom Junk Mill Drill Bit Manufacturer in China

As a leading custom junk mill drill bit manufacturer in China, we specialize in delivering high-performance, precision-engineered solutions for the oil and gas industry. Our drilling tools are designed for efficient milling of downhole obstructions. We offer extensive customization, providing tailored junk mills with various hardfacing options and cutting inserts to meet your specific drilling challenges. Trust our expertise for reliable and durable tools.

Sinodrills - Your Trusted Junk Mill Drill Bit Manufacturer from China

Sinodrills is your trusted junk mill drill bit manufacturer from China, specializing in innovative and durable downhole tools. We provide a comprehensive range of custom junk mills and drill bits designed for efficient milling and drilling operations in the oil and gas industry. Our commitment to quality and precision ensures that our tools deliver superior performance, helping you tackle challenging drilling environments with confidence and reliability.

Junk Mill Drill Bit Benefits

Obstruction Removal: These tools are expertly designed to mill and break up various junk and debris, such as lost cones, casing parts, or other metal objects, ensuring a clear path for continued drilling operations.

Enhanced Drilling Efficiency: By quickly clearing the wellbore of obstructions, junk mills reduce non-productive time, allowing drilling to resume swiftly and improving overall operational efficiency and cost-effectiveness.

Improved Safety: Using a dedicated tool to remove junk minimizes the risk of damage to expensive drill bits and other downhole equipment, enhancing safety and protecting valuable assets.

Cost Savings: By preventing damage to expensive bits and avoiding extensive fishing operations, junk mills contribute to significant cost savings, making them an economical choice for wellbore maintenance.

Junk Mill Drill Bit Design

Cutting Inserts and Hardfacing: Bits are often dressed with extremely hard materials like tungsten carbide inserts or crushed carbide matrix. This provides superior wear resistance and durability, allowing them to effectively mill through very hard rock and metal objects.

Body and Blade Design: The tool body is typically made from high-strength, heat-treated alloy steel. Designs vary, from flat-bottomed to concave, and may include integral blades or stabilizing pads to ensure the bit stays centered and maximizes milling performance.

Circulation Ports: Strategically placed ports and fluid channels are integrated into the design. These ports direct drilling fluid to the cutting face for cooling, and help to efficiently remove cuttings and debris from the bottom of the hole.

Face Profile: The face profile, such as flat, convex, or concave, is a key design element. A concave face, for example, is effective for milling bit cones or other rounded objects by keeping them centered under the mill for maximum grinding efficiency.

Various Junk Mill Drill Bit

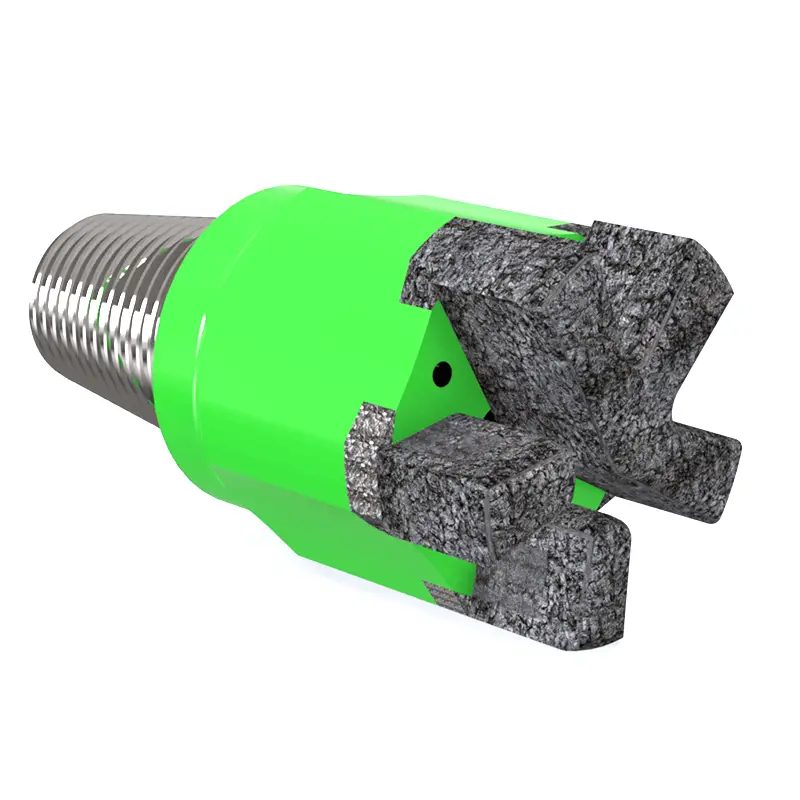

3 blade junk mill drill bits

We specialize in manufacturing and supplying 3-blade junk mill drill bits for the oil and gas industry. These tools are engineered with three robust blades, ensuring a balanced and stable milling action. This design is highly effective for milling through various downhole obstructions like cement, bridge plugs, and smaller metallic objects, providing a reliable solution for wellbore cleanup and maintenance.

5 blade junk mill drill bits

We specialize in providing 5-blade junk mill drill bits, expertly designed for heavy-duty milling applications. Our tools feature a robust five-blade configuration, enhanced with premium hardfacing and cutting inserts for maximum durability and penetration. We offer customized solutions to efficiently mill various downhole obstructions, including cement and steel, ensuring a successful drilling operation.

API oilfield flat bottom junk mill drill bits

We specialize in API oilfield flat bottom junk mill drill bits, providing a wide range of sizes and designs to suit various downhole challenges. Our mills are engineered with a flat cutting face, ensuring efficient and complete removal of debris, from lost tools to cement plugs. We provide tools with superior hardfacing and cutting inserts for exceptional durability and performance, enhancing your drilling efficiency and safety.

flat face junk mill drill bits for rock drilling

We provide high-performance flat bottom junk mill drill bits designed specifically for rock drilling and mining applications. These mills are engineered with a flat cutting face and robust crushed tungsten carbide hardfacing to aggressively mill through very hard and abrasive rock, as well as broken formations. This design is highly effective for clearing tough downhole obstructions.

carbide junk mill drill bits

We provide premium carbide junk mill drill bits designed for superior performance in oil and gas drilling. Our mills feature high-grade tungsten carbide inserts and hardfacing, ensuring exceptional durability and cutting efficiency. These tools are ideal for milling through challenging downhole obstructions like lost bits, casing, and cement, helping you save time and money.

inserted mill drill bits for mining

We specialize in manufacturing inserted mill drill bits for mining. Our bits are designed for maximum efficiency and durability in hard rock and abrasive formations. We provide high-quality tungsten carbide inserts tailored to your specific drilling needs, ensuring superior wear resistance and extended tool life. Trust our expertise for reliable, high-performance mining drilling tools.

Customize Your Desired Junk Mill Drill Bit

Hardfacing Materials

We offer a variety of hardfacing options to maximize tool longevity and performance. Our choices include crushed carbide, tungsten carbide inserts, and other proprietary materials. We apply the hardfacing in specific patterns to optimize milling efficiency and wear resistance, tailoring the tool for different rock types and metal obstructions you may encounter.

Cutting Structure Design

We can customize the cutting structure to match your operational requirements. This includes variations in the number of blades (3 to 6), their orientation, and the type and placement of inserts. Whether you need a flat-bottom mill for general milling or a concave design to capture and mill a specific type of junk, we can design the ideal solution.

Mill Body & Connection

The tool body is the foundation of the junk mill. We offer customization of the body material, ensuring it can withstand the torsional and compressive forces of your drilling environment. We also provide a range of standard and custom API connections, allowing seamless integration with your existing drill string.

Size and Configuration

We manufacture junk mills in a wide range of sizes to fit any wellbore diameter. Additionally, we can configure the tool with specific features such as fluid circulation ports for efficient debris removal, or stabilizer pads to maintain a centered position during operation. We ensure every aspect is optimized for your drilling project.

what is junk mill?

A junk mill is a specialized downhole drilling tool used in the oil and gas industry to clear obstructions from a wellbore. Unlike a conventional drill bit, which is designed to cut through rock, a junk mill’s primary purpose is to mill, grind, and break up various types of “junk” or debris that have fallen into the well.

This debris can include lost equipment like bit cones, metal fragments, tubulars, or even cement and other hard materials. By grinding these objects into small, manageable pieces, a junk mill allows them to be circulated out of the wellbore, enabling drilling or other well operations to continue without the need for a more complex and costly “fishing” operation.

what is junk mill drill bit made of?

A junk mill drill bit is a robust downhole tool designed for milling through metal, cement, and other hard materials. Its construction is centered on a strong steel body that is then fortified with extremely hard, wear-resistant materials to create the cutting surfaces. The combination of these materials is crucial for the tool’s ability to grind up downhole obstructions effectively.

High-Strength Alloy Steel Body: The foundation of the junk mill is a heat-treated alloy steel body, such as AISI 4145HM. This material provides the necessary toughness and durability to withstand the intense torsional and compressive forces encountered during milling.

Tungsten Carbide: Tungsten carbide is the primary cutting material. It is applied to the bit’s face and blades in various forms, including crushed carbide embedded in a matrix or as individual inserts. This super-hard material is what allows the mill to grind through steel and other tough materials.

Hardfacing Matrix: To bond the crushed tungsten carbide particles to the steel body, a tough matrix material is used, often a nickel-containing brass or a proprietary alloy. This matrix holds the cutting particles firmly in place, ensuring the mill maintains its aggressive cutting action.

Cutting Inserts: In some designs, especially for milling cemented-in tubulars, the junk mill utilizes discrete tungsten carbide inserts. These are precision-manufactured shapes that are brazed into pockets on the bit face, providing a more aggressive and faster cutting action.

what is junk mill drill bit used for?

A junk mill is primarily used in the oil and gas industry for a range of wellbore remediation and intervention operations. Its main purpose is not to drill new hole in rock but rather to remove or break up obstructions that can halt or compromise drilling, completion, or workover operations. By milling these objects into small, manageable pieces, it allows them to be circulated out of the wellbore, restoring the full diameter and enabling subsequent downhole activities to proceed smoothly.

Milling Downhole Debris: Junk mills are the go-to tool for grinding up lost or fallen equipment such as drill bit cones, pipe fragments, wireline tools, or other metal objects that can block the wellbore and prevent further operations.

Removing Cement and Plugs: They are highly effective for milling out excess cement, bridge plugs, or other types of downhole sealing tools. This allows operators to clear a path to a deeper section of the wellbore.

Clearing Casing Obstructions: When a section of casing is collapsed, deformed, or has scale buildup, a junk mill can be used to ream out the obstruction and restore the casing to its full internal diameter, ensuring a smooth path for other tools.

Preparing for Sidetracking: In complex directional drilling, a junk mill can be used to mill a window or section of casing. This creates a new exit point for the drill string, allowing a new wellbore to be drilled from that point.

Well Abandonment: Junk mills are often a critical part of a well’s plug and abandonment process. They are used to mill away sections of casing to facilitate the placement of cement plugs for a permanent well closure.

Send Your Inquiry Now

All-in-one Junk Mill Drill Bit Solutions for Your Project

We offer all-in-one junk mill drill bit solutions, providing comprehensive tools and expertise for your drilling project. Our custom-engineered junk mills are designed to efficiently handle a variety of downhole obstructions, from lost equipment to hardened cement. We provide tailored designs, ensuring you have the right tool for optimal performance and successful wellbore remediation.