Custom Mining Roof Bolts Manufacturer in China

As a custom mining roof bolts manufacturer in China, we offer tailored solutions for underground mining support needs. Our roof bolts are produced from reliable steel grades, with flexible sizes, thread types, and surface treatments. We support bulk orders, consistent quality control, and stable supply for global mining and construction projects.

Sinodrills - Your Trusted Mining Roof Bolts Manufacturer from China

Sinodrills is your trusted mining roof bolts manufacturer from China, offering dependable ground support solutions for underground mining. We provide custom sizes, thread designs, and surface finishes to match different rock conditions. With stable production and strict inspection, we support wholesalers, contractors, and mining projects worldwide.

Mining Roof Bolts Benefits

Improved Underground Safety – Mining roof bolts reinforce loose rock layers and stabilize mine roofs, reducing rock fall risks, improving working conditions, and protecting miners, equipment, and daily underground operations.

Enhanced Ground Stability – By anchoring rock strata together, roof bolts distribute stress evenly, control deformation, limit ground movement, and help maintain long-term tunnel and roadway stability.

Cost-Effective Support Solution – Roof bolts require less steel and installation time than heavy supports, lowering labor costs, minimizing maintenance, and increasing overall mining efficiency.

Flexible Application – Mining roof bolts suit different geological conditions and mine designs, with various lengths, diameters, anchoring methods, and surface treatments available for specific roof control needs.

Mining Roof Bolts Applications

Underground Coal Mining – Mining roof bolts are widely used to support coal mine roofs, control rock movement, and prevent collapses, ensuring safe working conditions and continuous production in longwall and room-and-pillar operations.

Hard Rock Mining – In metal and non-metal mines, roof bolts stabilize fractured rock masses, improve tunnel integrity, and support shafts, drifts, and crosscuts under high stress conditions.

Roadway and Tunnel Support – Roof bolts are applied in mine roadways and access tunnels to reinforce surrounding rock, reduce deformation, and maintain long-term stability during excavation and operation.

Rehabilitation and Ground Control – Mining roof bolts are used to strengthen aging mine openings, repair damaged roof areas, and enhance ground control measures in existing underground structures.

Various Mining Roof Bolts

coal mining roof bolts

Coal mining roof bolts, we offer reliable ground support solutions for underground coal mines. Our roof bolts are manufactured from durable steel, with stable load capacity and consistent threading. We provide custom lengths, diameters, and surface treatments to match different coal seam conditions and support safer, more efficient mining operations.

resin mining roof bolts

Resin mining roof bolts, we offer reliable anchoring solutions for underground support systems. These bolts use fast-setting resin to bond steel bolts with surrounding rock, providing immediate load capacity. Our resin roof bolts are available in different sizes and designs, suitable for coal and hard rock mining applications worldwide.

self drilling anchor bolts for mining

Self drilling anchor bolts for mining are designed for fast installation and reliable ground support in unstable rock conditions. We offer complete systems including hollow bars, drill bits, couplers, and plates. With flexible sizes, thread types, and surface treatments, our solutions support safe, efficient mining and underground construction projects worldwide.

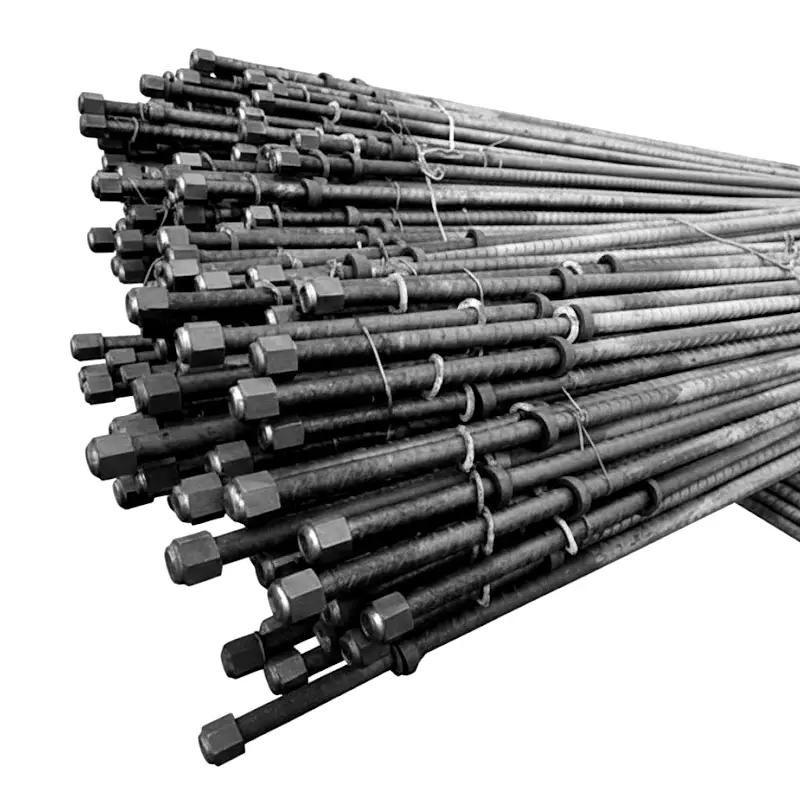

mine roof thread steel anchor bolt

Mine roof thread steel anchor bolts are designed to provide reliable roof support in underground mining operations. We offer threaded steel bolts with stable load capacity, accurate threads, and consistent quality. Available in custom lengths, diameters, and surface treatments, our anchor bolts support safe installation and long-term ground stability.

self drilling mining roof bolts

Self drilling mining roof bolts are designed to drill, grout, and anchor in one operation, making them ideal for weak or fractured rock conditions. We offer complete systems with hollow bars, drill bits, plates, and couplers. Custom sizes, thread types, and surface treatments support efficient, safe underground mining operations.

Customize Your Desired Mining Roof Bolts

Material Grade Selection

We customize mining roof bolts using different steel grades to match load requirements and geological conditions. By adjusting strength, ductility, and toughness, we ensure bolts perform reliably under varying stress levels and provide consistent support throughout the mine’s service life.

Bolt Length and Diameter

We tailor bolt length and diameter according to roof thickness and rock stability. Proper sizing allows effective anchorage in competent strata, improves load transfer, and avoids over-design, helping mining projects balance safety, performance, and cost efficiency.

Thread Type and Connection Design

We offer customized thread types and connection systems to suit installation methods and equipment. Optimized threads improve torque transfer, ensure secure plate fastening, and maintain compatibility with different drilling tools, resins, or grouting systems used on site.

Surface Treatment and Corrosion Protection

We apply suitable surface treatments based on mine environments, such as galvanizing or coatings. These options enhance corrosion resistance, extend service life, and maintain bolt strength in humid, corrosive, or chemically aggressive underground conditions.

All-in-one Mining Roof Bolts Solutions for Your Project

Mining roof bolts solutions for your project are designed to improve underground safety and ground stability. We offer a full range of roof bolts with custom lengths, diameters, thread types, and surface treatments. Our solutions support different mining conditions, ensuring reliable installation, consistent performance, and long-term roof control for underground operations.