OCTG, or Oil Country Tubular Goods, plays a critical role in oil and gas drilling operations. These high-strength steel pipes—including casing, tubing, and drill pipes—provide structural support, fluid transport, and safety in wells. Understanding OCTG helps operators ensure efficient and reliable well performance.

High-quality OCTG products are essential for withstanding extreme pressures, temperatures, and downhole conditions. Proper selection, inspection, and maintenance of OCTG components prevent failures, reduce downtime, and extend service life. This guide explores what OCTG is, its main types, and why it matters for safe and efficient oil and gas operations.

What is OCTG?

OCTG, or Oil Country Tubular Goods, refers to a range of steel pipes used in the oil and gas industry for drilling, production, and well completion. These pipes provide structural support, enable fluid transport, and ensure well integrity under extreme downhole conditions. They are essential for safe and efficient oil and gas operations.

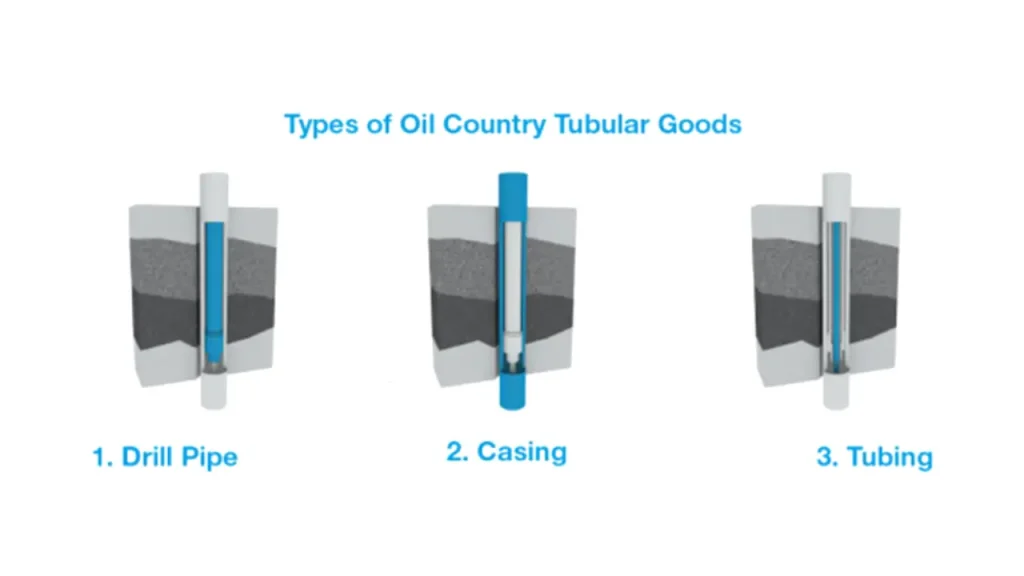

OCTG typically includes three main types: casing, tubing, and drill pipe. Casing stabilizes the wellbore and isolates different underground formations, tubing transports oil and gas to the surface, and drill pipes connect the drill bit to the rig while transmitting torque and drilling fluids. All OCTG products are manufactured to strict API standards for durability and reliability.

OCTG Material Handling Systems

OCTG material handling systems are essential solutions used to move, store, and protect pipes, tubing, and casings throughout drilling operations. These systems improve workflow efficiency while reducing safety risks and equipment damage. By using specialized racks, conveyors, and lift-assist tools, companies can streamline OCTG logistics and maintain consistent performance across demanding oilfield environments.

Pipe Racks – Pipe racks keep OCTG pipes organized, stable, and protected by preventing metal-to-metal contact and unnecessary pressure. Their structured layout allows safer stacking, easier retrieval, and smoother workflow movement. This reduces manual handling risks while improving operational efficiency and long-term storage conditions in demanding drilling environments.

Automated Handling Equipment – Automated systems, including robotic lifters and conveyors, reduce manual labor involvement while improving safety and speed. These technologies provide precise, consistent movement of heavy OCTG materials, prevent human error, and support continuous operations. They are essential for facilities aiming to modernize and streamline their tubular handling processes effectively.

Hydraulic Lifting Tools – Hydraulic lifting tools deliver controlled lifting power to handle heavy OCTG pipes safely and accurately. They reduce accident risks, improve handling consistency, and assist operators in tight or high-pressure environments. These tools provide essential mechanical support where manual handling is unsafe or operationally inefficient.

Pipe Conveyors – Pipe conveyor systems transport OCTG pipes smoothly across storage yards and work zones, minimizing worker strain and drop hazards. They ensure faster, safer material transfer during high-demand drilling schedules. Their continuous movement support helps maintain efficient logistics flow in both onshore and offshore operational environments.

Tubular Storage Solutions – Tubular storage systems protect OCTG casings and tubing from corrosion, weathering, and accidental impacts. They offer organized compartments for easier inspections, faster retrievals, and overall safer handling. These solutions extend tubular lifespan, improve inventory control, and support smooth operations in fast-paced drilling projects.

Types of Oil Country Tubular Goods

Oil Country Tubular Goods (OCTG) are specialized steel pipes used in oil and gas drilling, production, and well completion. They provide structural support, enable fluid transport, and maintain well integrity under extreme downhole conditions. High-quality OCTG ensures safe, efficient, and reliable operations across various drilling environments.

- Casing Pipes: Casing pipes stabilize the wellbore and prevent collapse while isolating different underground formations. We provide API-compliant casing that withstands high pressures and temperatures, ensuring structural integrity and safe drilling operations in challenging downhole conditions.

- Tubing Pipes: Tubing pipes transport oil, gas, and other fluids from the reservoir to the surface efficiently. We manufacture tubing to optimize flow, resist corrosion, and maintain integrity under high-pressure and high-temperature well conditions, ensuring reliable production.

- Drill Pipes: Drill pipes connect the drill bit to the rig, transmitting torque and drilling fluids during operations. We produce high-strength drill pipes with precise threading and durable steel to withstand axial loads, torque, and harsh downhole environments.

Types of OCTG Drill Pipes

OCTG drill pipes are essential for efficient and safe drilling operations in the oil and gas industry. They are designed to transmit torque, drilling fluids, and weight to the drill bit while withstanding extreme pressures and harsh downhole conditions.

Understanding the types of drill pipes helps operators select the right pipe for specific well requirements.

Recommended Drill Pipes

Regular Weight Drill Pipe

Regular weight drill pipes are standard-grade pipes designed for general drilling operations. We manufacture these pipes with high-strength steel and precision threading, ensuring durability and reliable performance under normal downhole pressures and loads. They are suitable for most conventional drilling projects.

These pipes provide a balance between strength and flexibility, making them ideal for typical well depths. Regular weight drill pipes are cost-effective and widely used, offering dependable performance while meeting API standards for safety and quality in oil and gas drilling operations.

Heavy Weight Drill Pipe

Heavy weight drill pipes are thicker and stronger than regular pipes, designed to handle higher torque, axial loads, and deeper wells. We produce these pipes with enhanced steel grades and reinforced threading to withstand challenging drilling conditions and extreme pressures.

These pipes provide additional stiffness and durability, reducing pipe bending and fatigue in extended-reach or deviated wells. Heavy weight drill pipes are particularly useful for long, deep, or high-stress drilling projects, ensuring safety, stability, and operational efficiency throughout the well’s drilling process.

Slim Hole Drill Pipe

Slim hole drill pipes are narrower in diameter, designed for drilling smaller wells or exploration projects. We manufacture these pipes with high-quality steel while maintaining strength and performance despite the reduced size.

Slim hole drill pipes are ideal for cost-effective operations where space and weight are limited. They allow efficient drilling in restricted or difficult formations, offering flexibility without compromising structural integrity or reliability in exploration and specialized drilling applications.

Premium or Alloy Drill Pipe

Premium or alloy drill pipes use advanced steel alloys for enhanced strength, corrosion resistance, and fatigue life. We produce these pipes to meet demanding drilling requirements, such as high-pressure, high-temperature (HPHT) wells, or sour service environments.

These pipes provide superior performance in extreme downhole conditions, resisting wear, corrosion, and stress-induced failures. Premium drill pipes ensure long-term reliability, reduced maintenance, and safer drilling operations, making them ideal for challenging oil and gas projects worldwide.

OCTG Casing and Tubing Pipe

OCTG casing and tubing pipes are essential for oil and gas well integrity and production efficiency. Casing stabilizes the wellbore, while tubing transports fluids from the reservoir to the surface. High-quality pipes ensure safe, reliable, and long-lasting performance under extreme pressures and downhole conditions.

- Casing Pipes: Casing pipes provide structural support to the wellbore, preventing collapse and isolating different formations. We manufacture API-compliant casing that withstands high pressures and temperatures, ensuring operational safety and long-term well integrity in challenging drilling environments.

- Tubing Pipes: Tubing pipes are used to transport oil, gas, and other fluids efficiently from the reservoir to the surface. We produce tubing with precise dimensions and high-strength steel, optimizing flow, minimizing leaks, and ensuring reliable production under harsh downhole conditions.

- Premium Casing and Tubing: Premium or alloyed casing and tubing offer enhanced resistance to corrosion, wear, and fatigue. We provide these pipes for high-pressure, high-temperature (HPHT), or sour service wells, ensuring durability, reduced maintenance, and safe operation.

- Custom Sizes and Grades: We offer custom OCTG casing and tubing in various lengths, diameters, and grades to meet project-specific requirements. Tailored solutions ensure compatibility with rigs, optimize well performance, and address unique downhole conditions effectively.

- Inspection and Maintenance: Regular inspection and maintenance of casing and tubing are crucial for performance and safety. We emphasize thorough checks for wear, corrosion, and defects, extending service life and preventing costly failures in oil and gas operations.

Why OCTG Matters?

OCTG, or Oil Country Tubular Goods, is critical for safe, efficient, and reliable oil and gas operations. High-quality OCTG provides structural support, ensures fluid transport, and maintains well integrity under extreme pressures and temperatures. Choosing the right OCTG products minimizes risks, reduces downtime, and enhances overall drilling performance.

- Wellbore Stability: OCTG casing stabilizes the wellbore, preventing collapse and isolating different underground formations. We ensure proper selection and installation, maintaining structural integrity and safety throughout the drilling and production process.

- Efficient Fluid Transport: Tubing allows smooth and reliable transport of oil, gas, and other fluids from the reservoir to the surface. We use high-quality pipes to optimize flow, prevent leaks, and enhance operational efficiency.

- Durability and Longevity: High-strength OCTG resists corrosion, wear, and fatigue, extending service life. We provide pipes that endure extreme downhole conditions, reducing maintenance costs and ensuring long-term reliable performance.

- Safety Assurance: Using API-compliant OCTG minimizes the risk of equipment failure, accidents, or environmental hazards. We prioritize quality and compliance to protect personnel, equipment, and the surrounding environment during drilling operations.

- Operational Efficiency: Properly selected and maintained OCTG ensures smooth drilling and production processes. We help optimize equipment performance, reduce downtime, and enhance productivity, contributing to cost-effective and successful oil and gas projects.

Conclusion

OCTG is fundamental to the safety, efficiency, and reliability of oil and gas drilling projects. Casing, tubing, and drill pipes provide structural integrity, fluid transport, and operational stability. Selecting the right OCTG products ensures wells function safely and efficiently, minimizing risks and downtime in challenging environments.

Proper maintenance and inspection of OCTG components are equally important. Regular checks for corrosion, wear, and defects help extend the service life of pipes and prevent operational failures. High-quality OCTG combined with effective maintenance maximizes well performance and protects both equipment and personnel during drilling operations.

For reliable, durable, and high-performance OCTG and drilling tools, get wholesale drilling tools from our Sinodrills. We provide precision-engineered, API-compliant products tailored for demanding oil and gas applications. Partnering with Sinodrills ensures safe, efficient, and long-lasting solutions for all your drilling projects.