Drilling through challenging ground conditions can often be a complex and time-consuming endeavor. When faced with unstable formations, loose overburden, or stubborn boulders, traditional drilling methods can fall short, leading to delays and increased costs. This is where the innovative Odex drilling system steps in as a game-changer.

The Odex drilling method, a type of eccentric overburden drilling, offers a highly efficient solution for simultaneously drilling and casing a borehole. By providing immediate support to the bore, it prevents collapse and ensures a stable hole, making it an indispensable technique for a wide range of construction and geotechnical applications.

What is Odex Drilling?

Odex drilling, short for Overburden Drilling EXcentric, is a specialized drilling method designed for efficiently creating cased boreholes in challenging ground conditions such as loose overburden, sand, gravel, and boulder-laden formations. It works by utilizing an eccentric drill bit that is slightly larger than the outer casing.

As the drill bit rotates and drills, its eccentric design creates a pilot hole wide enough for the casing to follow immediately behind, simultaneously drilling and installing the casing in a single pass. This continuous casing advancement provides immediate borehole stability, preventing collapse and ensuring a clean, open hole, which is crucial in unstable or caving ground.

Odex Drilling System Components

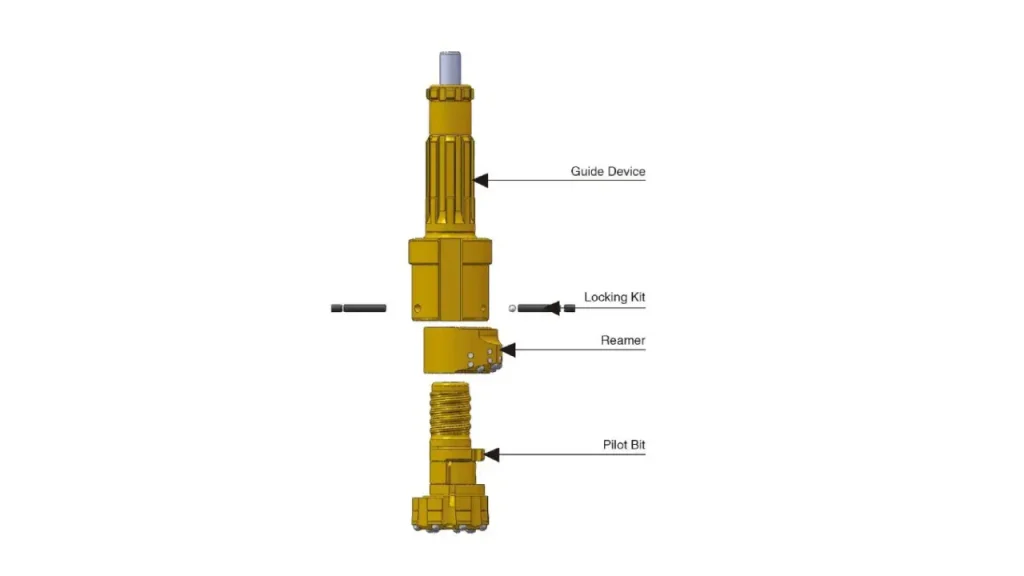

Based on the image provided, the Odex drilling system is composed of specialized components working in unison for efficient simultaneous drilling and casing. Each part plays a critical role in the system’s ability to create cased boreholes in challenging ground conditions.

- Guide Device: This upper section connects to the drill string and the DTH hammer. It transmits rotation and impact energy to the entire assembly, guiding the drill bit and casing through the ground with precision and stability during operation.

- Locking Kit: The locking kit securely fastens the reamer to the guide device. This small but vital component ensures that the reamer remains in its extended position during drilling, providing the necessary cutting diameter for the casing to follow.

- Reamer: The reamer is the eccentric cutting wing that swings out during drilling. Its function is to enlarge the pilot hole, creating a bore wide enough for the casing to pass through, and it retracts when rotation is reversed for easy extraction.

- Pilot Bit: Positioned at the very bottom, the pilot bit is the primary cutting tool. It initiates the borehole, drilling ahead of the reamer and casing, effectively creating the initial path through the rock or overburden.

How Does Odex Work?

The ODEX (Overburden Drilling Excentric) system is a specialized drilling method that allows for simultaneous drilling and casing installation through unstable ground. It uses an eccentric reamer bit that swings out during forward rotation to drill a hole slightly larger than the permanent casing, which follows immediately behind.

ODEX System Operation

- Eccentric Reaming Action: The system employs a pilot bit and a hinged, eccentric reamer wing that is forced outward by rotation and impact. This reamer enlarges the hole diameter just enough for the surrounding steel casing to be driven down directly behind the drill bit assembly.

- Simultaneous Casing Advancement: A portion of the down-the-hole (DTH) hammer‘s impact energy is transferred from a shoulder on the guide device to a special casing shoe at the bottom of the casing string. This drives the casing down concurrently with the drilling, providing immediate borehole stability.

- Retrievable Drill String: Once the desired depth is reached, the drill rotation is carefully reversed. This action causes the eccentric reamer wing to swing inwards and retract. The entire drill bit assembly can then be easily pulled out through the inside of the already-installed, permanent casing.

Odex Drilling Benefits

Odex drilling offers significant benefits, particularly when dealing with challenging ground conditions. Its core advantage lies in its ability to simultaneously drill and case a borehole, providing immediate stability and preventing hole collapse in unstable or caving formations like sand, gravel, and overburden.

This integrated approach dramatically increases drilling efficiency, reducing overall project time and associated costs by eliminating the need for separate drilling and casing operations.

Key benefits of Odex drilling include:

- Enhanced Hole Stability: By advancing the casing concurrently with drilling, Odex systems immediately support the borehole walls, preventing collapse and ensuring a stable, open hole in even the most challenging, loose, or fractured ground.

- Increased Efficiency and Speed: The simultaneous drilling and casing process streamlines operations, leading to faster penetration rates and reduced project timelines compared to conventional methods that require multiple passes.

- Cost Savings: Reduced drilling time, minimized risk of hole collapse, and less need for remedial work contribute to significant cost savings on projects, making Odex a highly economical choice for complex conditions.

- Versatility: Odex systems are effective in a wide range of geological formations, including overburden, boulders, gravel, and fractured rock, making them suitable for diverse applications like water wells, micropiles, and geotechnical investigations.

- Improved Safety: By maintaining borehole integrity throughout the drilling process, Odex reduces the risks associated with unstable ground, enhancing safety for personnel and equipment on site.

Odex Drill Bits

Recommended Odex Drilling Systems

Odex drill bits are the specialized cutting tools at the heart of the Odex drilling system, designed for simultaneous drilling and casing in unstable ground. Their unique eccentric design allows them to create a borehole slightly larger than the outer casing.

This enables the casing to follow immediately behind the bit, providing continuous support and preventing hole collapse. Key characteristics include:

- Eccentric Reamer: A crucial component that swings out during drilling to enlarge the pilot hole, allowing the casing to pass.

- Pilot Bit: The central cutting element that initiates the borehole.

- Retractable Design: The reamer can be retracted by reversing rotation, allowing the drill string to be pulled out through the installed casing.

- Robust Construction: Made from high-strength materials like tungsten carbide to withstand challenging drilling conditions.

Odex and Symmetrix Drilling Methods

Odex and Symmetrix are two prominent overburden drilling methods, both designed for simultaneous drilling and casing in challenging ground conditions, yet they employ different mechanisms for reaming the hole. Both systems use a DTH hammer to provide the percussive energy, allowing for efficient penetration through diverse geological formations, from loose overburden to hard rock and boulders.

Their shared goal is to maintain borehole stability and accelerate project completion by combining drilling and casing installation into a single, continuous operation.

- Odex (Overburden Drilling EXcentric): This system utilizes an eccentric reaming principle. It features a pilot bit and a reamer wing that swings out during rotation, creating a hole larger than the casing. Once the desired depth is reached, reversing the rotation causes the reamer wing to retract, allowing the drill string to be retrieved through the installed casing, making the bit reusable for the next hole. Odex is typically favored for shorter holes and normal overburden conditions, offering a cost-effective and retrievable solution.

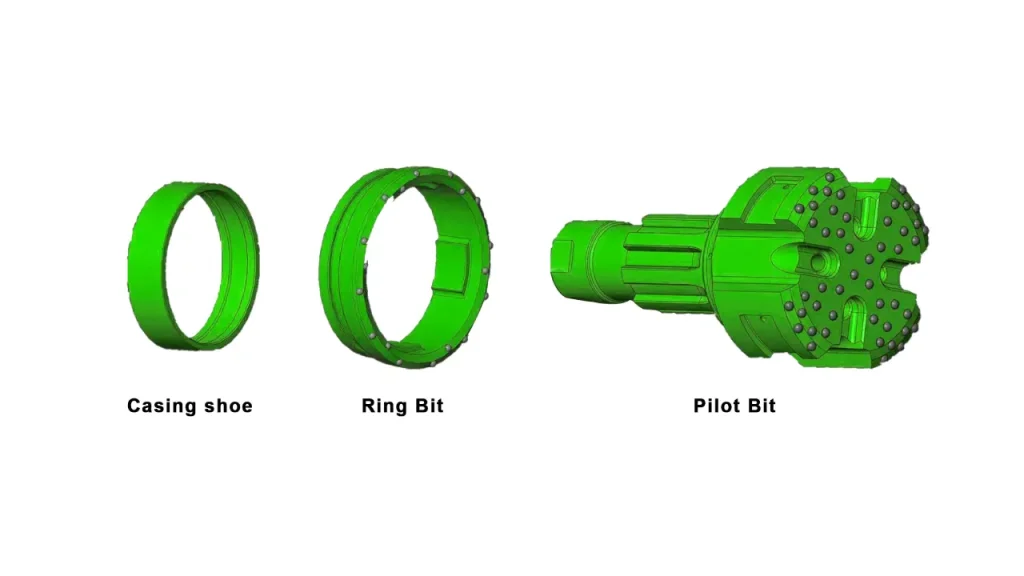

- Symmetrix (Concentric Overburden Drilling): In contrast to Odex’s eccentric design, Symmetrix is a concentric drilling system. It uses a pilot bit and a ring bit (or ring bit set) that together form a full-face drilling head, creating a consistently sized hole for the casing. The ring bit is either left in the hole permanently with the casing or can be designed to be retrievable depending on the specific system. Symmetrix is generally preferred for larger diameter holes, deeper drilling, and very hard, difficult ground conditions, as its concentric design offers superior straightness and robust performance through obstacles.

Where to Use Odex Drilling?

Odex drilling is a highly versatile method employed in various applications where drilling through challenging or unstable ground is required. Its ability to simultaneously drill and case a borehole makes it indispensable in preventing hole collapse and ensuring project success.

- Water Well Drilling: It’s ideal for creating stable and clean water wells, especially in areas with loose soil, sand, or gravel, where conventional drilling methods would struggle to maintain an open hole. The immediate casing prevents contamination and ensures the well’s integrity.

- Foundation and Micropiling: Odex is extensively used for establishing strong foundations and installing micropiles in unstable ground. It can penetrate overburden and boulders, allowing for secure anchoring into bedrock, which is crucial for structural stability.

- Geotechnical Investigations: When precise soil and groundwater samples are needed in caving formations, Odex provides a reliable solution. It maintains borehole integrity, allowing for accurate sample collection and in-situ testing without the risk of collapse.

- Environmental Drilling: For projects involving environmental remediation or monitoring in contaminated or unstable sites, Odex ensures that boreholes remain open and that there’s no cross-contamination between different layers, maintaining environmental safety.

What Size is Odex Casing?

Odex casing systems are available in a range of sizes to accommodate various drilling project requirements, typically correlating with the diameter of the borehole needed. The “Odex” designation often includes a number that refers to the approximate outer diameter of the pilot bit, which in turn dictates the size of the casing that can be simultaneously installed.

This flexibility allows for efficient casing in different ground conditions and for diverse applications, from smaller monitoring wells to larger foundation piles.

Common Odex casing sizes typically include:

- Odex 90: Designed to work with approximately 90mm pilot bits, allowing for casing around 114mm (4.5 inches) outer diameter.

- Odex 115: Suited for pilot bits around 115mm, with compatible casing often around 140mm (5.5 inches) outer diameter.

- Odex 140: For larger applications, it uses a 140mm pilot bit and typically installs casing around 168mm (6.6 inches) outer diameter.

- Odex 165, 190, and 240: These larger systems cater to increasingly larger casing diameters, with the Odex 240, for instance, able to use casing up to approximately 273mm (10.75 inches) outer diameter.

How Much Does It Cost to Replace Well Casing?

The cost to replace well casing varies significantly, typically ranging from $1,500 to $5,000 for repair work, but can be much higher depending on the project scope. The total price is heavily influenced by the well’s depth, the casing material chosen, and the complexity of accessing the damaged section deep underground, making professional assessment essential for an accurate quote.

- Well Depth and Diameter: Deeper wells require significantly more material and specialized equipment to remove and replace the damaged casing section. A greater diameter also increases the volume and therefore the cost of the new piping material needed for the replacement.

- Casing Material Type: The cost per foot ranges widely, with PVC being the most economical option at roughly $6–$10 per foot. Conversely, sturdier materials like galvanized or stainless steel pipe can increase the cost to $30–$130 per foot, which is often necessary for deeper or rocky conditions.

- Extent of Damage and Labor: Minor cracks may only require a patch, keeping costs lower, whereas a full casing collapse necessitates more complex, costly, and time-consuming drilling equipment and labor. Difficult ground conditions, like large boulders or solid rock, also increase labor costs substantially.

Conclusion

In summary, Odex drilling stands out as a highly effective and efficient method for navigating challenging ground conditions. Its ability to simultaneously drill and case provides unmatched stability and significantly reduces project timelines, making it a valuable asset for various applications, from water well construction to foundation work. The reliability and precision offered by Odex systems contribute to safer and more successful drilling operations.

Choosing the right drilling tools is paramount to harnessing the full potential of Odex technology. High-quality components ensure optimal performance, durability, and cost-effectiveness in the long run. Investing in robust and precisely engineered drilling tools directly translates to increased productivity and fewer operational setbacks on site.

For all your drilling tool needs, including premium Odex systems and accessories, look no further than Sinodrills. As a leading manufacturer based in Qingdao, China, we offer a comprehensive range of wholesale drilling tools designed to meet the highest standards of quality and performance. Get wholesale drilling tools from Sinodrills and empower your projects with reliable, top-tier equipment.