Rotary Air Blast (RAB) drilling is a fundamental technique in mineral exploration and geotechnical investigation. This method utilizes compressed air to clear cuttings while a rotating drill bit pulverizes the rock, offering a cost-effective and efficient way to obtain geological samples.

Understanding RAB drilling is crucial for anyone involved in exploration or ground engineering. This guide will delve into the mechanics, applications, advantages, and limitations of RAB drilling, providing you with a comprehensive overview to optimize your next project.

What is RAB Drilling?

Rotary Air Blast (RAB) drilling is a drilling technique primarily used in mineral exploration and geotechnical investigations, particularly for shallow to medium depths. As the name suggests, it combines rotary action with compressed air to clear the borehole.

How Does RAB Drilling Work?

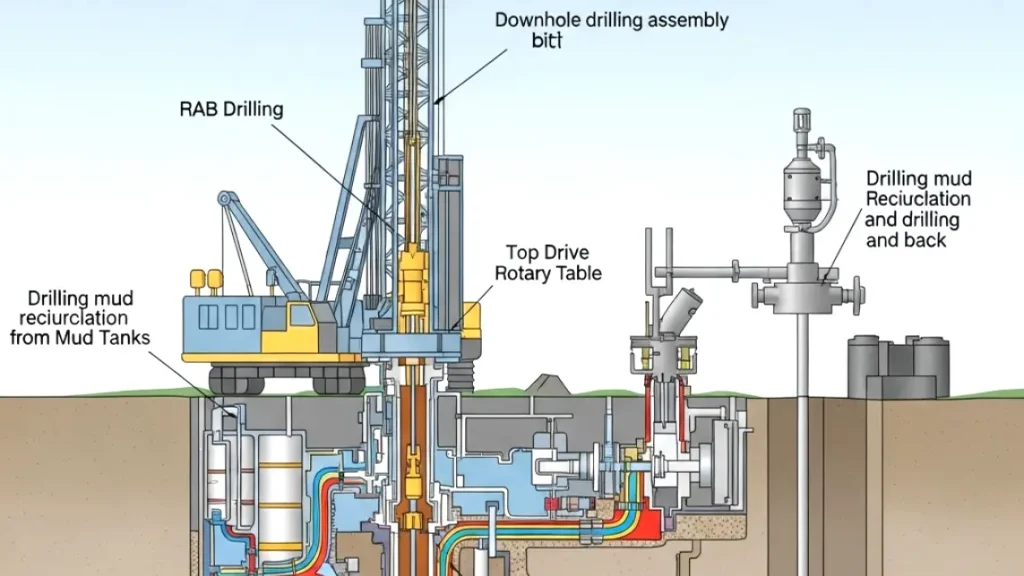

Rotary Air Blast (RAB) drilling operates on a straightforward principle that combines mechanical rotation with the power of compressed air. A drill rig drives a drill string, at the end of which is a drill bit, typically a drag bit or a button bit.

As the drill bit rotates, it grinds and pulverizes the rock at the bottom of the borehole. Simultaneously, a high-volume flow of compressed air is injected down the drill pipe. This air travels through the bit, picks up the fragmented rock cuttings, and carries them back to the surface through the annular space between the drill pipe and the borehole wall.

The continuous removal of cuttings by the air blast is crucial for efficient penetration, preventing the bit from grinding the same material repeatedly. This method is particularly effective in softer to medium-hard rock formations.

While some RAB systems might incorporate a down-the-hole (DTH) hammer for added percussive action in harder ground, the defining characteristic remains the use of air to clear the hole. The collected cuttings provide a continuous sample of the geology being drilled, allowing for real-time geological logging.

Here’s how RAB drilling works:

- Drill String Rotation: A drill bit at the bottom of the hole is rotated by the drill rig, mechanically breaking the rock.

- Compressed Air Injection: High-pressure compressed air is introduced down the drill pipe, exiting at the bit face.

- Cuttings Removal: The air blast carries the pulverized rock cuttings up the annulus (the space between the drill pipe and the borehole wall) to the surface.

- Sample Collection: Cuttings are collected at the surface for geological analysis, providing a continuous profile of the ground.

- Optional Percussion: In some RAB setups, a DTH hammer can be integrated to provide additional percussive blows to the bit, enhancing penetration in harder rock.

Percussion Rotary Air Blast Drilling

Percussion Rotary Air Blast (RAB) drilling is a specific variation of the broader RAB technique that significantly enhances its capability, especially in harder rock formations. While standard RAB primarily relies on the rotational grinding action and air flushing, Percussion RAB incorporates a Down-The-Hole (DTH) hammer directly behind the drill bit at the bottom of the borehole.

This DTH hammer delivers rapid, high-energy percussive blows to the drill bit, pulverizing the rock more effectively than rotation alone. The compressed air that drives the DTH hammer also serves the crucial function of continuously clearing the borehole of cuttings, carrying them to the surface for collection and geological analysis.

This combined action of rotary motion, percussive impact, and continuous air flushing makes Percussion RAB a highly efficient and faster drilling method for a wider range of geological conditions, bridging the gap between conventional RAB and more expensive core drilling.

Key aspects of Percussion Rotary Air Blast Drilling include:

- Combined Action: Integrates rotary drilling with a percussive DTH hammer for superior rock breaking.

- DTH Hammer: A pneumatic hammer located at the bottom of the hole delivers high-frequency impacts directly to the drill bit.

- Air Flushing: Compressed air powers the hammer and simultaneously clears rock cuttings up the annulus to the surface.

- Enhanced Penetration: Achieves significantly faster penetration rates, particularly in hard and abrasive rock types.

- Sample Collection: Cuttings are continuously collected at the surface, providing a detailed geological sample for analysis.

- Versatility: More effective than conventional RAB in a wider range of geological conditions, including harder rock.

- Cost-Effective: Offers a cost-efficient alternative for exploration and shallow geotechnical work compared to core drilling in certain formations.

RAB Drilling Tools

Recommended products

RAB drilling relies on a specialized set of tools designed to withstand the abrasive conditions and percussive forces involved in the drilling process, while also facilitating efficient sample recovery. These tools are selected based on the geological formation being drilled, the desired hole depth, and the specific capabilities of the drilling rig.

The primary components include the drill bits that directly break the rock, the drill rods that transmit power and air downhole, and the various ancillary equipment for handling cuttings and maintaining hole integrity. The quality and compatibility of these tools are paramount for achieving optimal penetration rates, maximizing bit life, and ensuring reliable geological sample collection.

Here are the essential RAB drilling tools:

RAB Drill Bits:

- Drag Bits: Used for softer, unconsolidated formations where cutting and scraping are effective.

- Button Bits (Carbide Insert Bits): More durable, featuring tungsten carbide inserts, ideal for medium to hard rock where impact and crushing are needed.

- Blade Bits: Suitable for softer ground, often with replaceable blades.

RAB Drill Rods: Hollow steel pipes that transmit rotation, percussive energy (if applicable), and compressed air to the drill bit. They are designed for quick coupling and uncoupling.

RAB Hammers (for Percussion RAB): Down-the-Hole (DTH) hammers used in Percussion RAB systems to provide additional percussive force to the drill bit in harder formations.

Air Compressors: Provide the high-volume, high-pressure compressed air necessary to power the hammer (if used) and flush cuttings from the borehole.

Sample Collection Systems: Cyclones, splitters, or simple collection bags used at the surface to capture and subdivide the rock cuttings for geological analysis.

Stabilizers: Used to ensure borehole straightness and reduce vibration by centralizing the drill string.

Casing: Sometimes used in unstable ground conditions near the surface to prevent the borehole from collapsing.

RAB Drilling Applications

Rotary Air Blast (RAB) drilling is a versatile and cost-effective technique widely employed across various industries, primarily due to its ability to rapidly penetrate and sample a broad range of geological formations. While often used for initial reconnaissance, its efficiency in obtaining large volumes of rock cuttings makes it suitable for numerous applications where a quick, representative geological profile is needed, and core recovery isn’t the primary objective. Its effectiveness shines in applications requiring shallow to medium-depth holes in relatively stable ground conditions.

Here are the primary applications of RAB Drilling:

Mineral Exploration:

- Reconnaissance Drilling: Quickly identifying potential mineralized zones over large areas.

- Grid Drilling: Systematically sampling at regular intervals to define the extent and grade of an orebody.

- In-fill Drilling: Providing denser sample coverage within known mineralized areas.

- Site Characterization: Assessing ground conditions for construction projects, including soil and rock type identification.

- Environmental Surveys: Drilling for baseline data or to delineate contamination plumes in overburden.

Water Well Drilling: For domestic, agricultural, or industrial water supply, particularly in unconsolidated or fractured rock formations.

Blast Hole Drilling: In smaller quarrying or construction operations where rapid, shallow holes are needed for explosives.

Pre-collar Drilling: Creating the initial, wider diameter portion of a borehole before switching to a different drilling method (e.g., diamond drilling for deeper core recovery).

Seismic Shot Holes: Drilling shallow holes for seismic exploration, where small explosive charges are detonated.

Conclusion

In conclusion, Rotary Air Blast (RAB) drilling offers a robust and economical solution for various shallow to medium-depth drilling requirements. Its efficiency in sampling and versatility across different ground conditions make it an invaluable technique for initial exploration and geotechnical assessments.

Mastering the nuances of RAB drilling can significantly enhance project outcomes, from optimizing operational costs to ensuring accurate geological data collection. By understanding its principles and proper application, you can leverage this method to its full potential.

For all your RAB drilling needs, consider Sinodrills. We offer a comprehensive range of wholesale RAB drilling tools, manufactured to high standards, ensuring reliability and performance for your projects.