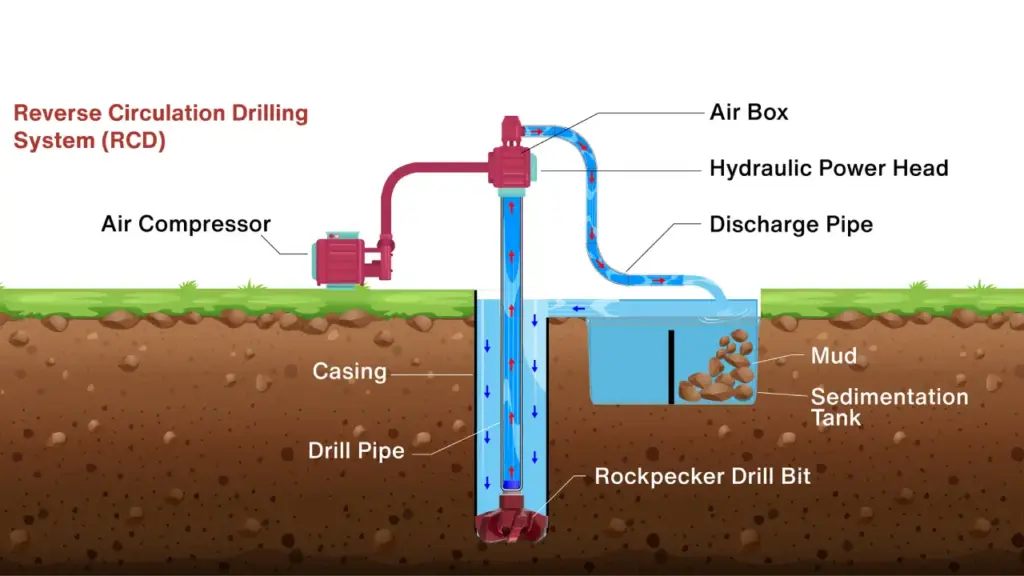

Reverse Circulation (RC) drilling stands as a prominent technique in mineral exploration and geotechnical investigations. This method employs a dual-walled drill pipe system where compressed air is forced down the outer tube. The air then lifts the pulverized rock cuttings through the inner tube to the surface, providing rapid and relatively uncontaminated samples for immediate analysis.

This blog post will delve into the intricacies of RC drilling, exploring its operational mechanics step by step. We will unravel how the downhole hammer pulverizes the rock, how the compressed air efficiently transports the cuttings, and the crucial role of the sampling system in ensuring representative samples. Join us to gain a comprehensive understanding of this vital drilling technique.

What is RC Drilling

What does RC drilling mean?

RC drilling, or reverse circulation drilling, is a method of percussion drilling that utilizes compressed air to forcefully eject rock cuttings from the drill hole. This technique employs dual-walled drill rods where compressed air is pushed down the outer tube, and the pulverized rock samples are forced back up through the inner tube to be collected at the surface.

RC drilling is favored in mineral exploration for its speed, cost-effectiveness, and ability to provide relatively dry, uncontaminated samples quickly for analysis.

What is RC Drilling in Mining?

Reverse Circulation (RC) drilling in mining is a rapid and cost-effective method primarily used for mineral exploration and early-stage resource definition. It utilizes a dual-walled drill pipe system and compressed air to extract rock samples. This method is highly valued for its ability to deliver relatively uncontaminated samples quickly, making it ideal for determining the presence and approximate grade of mineralization over large areas.

Here’s how it generally works:

- Dual-Walled Drill Rods: RC drilling employs specialized drill rods with an inner tube and an outer tube. Compressed air is forced down the annulus (the space between the inner and outer tubes).

- Downhole Hammer and Bit: At the bottom of the drill string, a pneumatic (air-driven) downhole hammer rapidly impacts a tungsten-carbide-tipped drill bit. This pulverizes the rock at the bottom of the borehole.

- Reverse Circulation of Cuttings: The high-pressure air, along with the rock cuttings (chips), is then forced up through the inner tube of the drill rods. This “reverse circulation” prevents contamination from the borehole walls.

- Sample Collection: Once the air and cuttings reach the surface, they are directed into a cyclone separator. The cyclone slows the air flow, causing the rock chips to drop into sample bags, which are collected at regular intervals (e.g., every meter).

- Real-time Analysis: The collected rock chips provide a continuous, representative sample of the geology being drilled, allowing geologists to assess the mineral content in real-time, guiding further exploration decisions.

How RC Drilling Works

RC drilling operates using a dual-walled drill rod system. Compressed air is forced down the outer tube, powering a downhole hammer that pulverizes the rock. The resulting rock cuttings are then pushed upwards through the inner tube by the returning high-pressure air.

At the surface, a cyclone separator collects these samples for analysis while the air is expelled. This method allows for rapid drilling and the collection of relatively dry and uncontaminated samples.

Key aspects of how RC drilling works include:

- Dual-walled drill rods: An outer tube for compressed air and an inner tube for sample return.

- Downhole hammer: A pneumatic piston that rapidly impacts the drill bit to break rock.

- Compressed air: Used to power the hammer and transport cuttings to the surface.

- Drill bit: Typically features tungsten carbide buttons for effective rock penetration.

- Cyclone separator: A device at the surface that separates rock cuttings from the air stream for collection.

RC Drilling Tools

RC drilling utilizes a specific set of tools designed for efficient and rapid sample collection. These tools work together to pulverize rock and transport the cuttings to the surface via compressed air. Key components include:

- RC Hammer: A downhole pneumatic hammer that rapidly impacts the drill bit to break the rock. It features an inner tube for cuttings to pass through.

- RC Drill Bits: Specialized bits with tungsten carbide buttons designed for percussion drilling and efficient cutting generation. They have channels to direct cuttings into the inner tube of the hammer.

- Dual-Wall Drill Rods: These rods have an outer tube for the compressed air to travel down and an inner tube for the cuttings to be forced back up to the surface.

- Subs and Adapters: Various subs and adapters are used to connect different components of the drill string, ensuring compatibility between the rig, rods, hammer, and bit.

- Air Swivel: A component at the top of the drill string that allows the drill rods to rotate while high-pressure air is injected.

- Cyclone Separator: A surface unit that separates the rock cuttings from the returning air stream, allowing for sample collection.

How Deep Can RC Drilling Go?

The depth capability of RC drilling is influenced by several factors, including the power of the drilling rig, the air pressure supplied by the compressor, the diameter of the drill rods and bit, and the geological conditions encountered. Generally, RC drilling can achieve depths ranging from 300 to 500 meters (approximately 1,000 to 1,600 feet) routinely.

However, with larger and more powerful rigs, and favorable ground conditions, depths exceeding 800 meters (around 2,600 feet) have been reported. Groundwater can significantly impede depth, requiring increased air pressure to keep the hole dry and evacuate cuttings effectively.

The cost of RC drilling increases with depth due to the need for more powerful compressors and potentially larger diameter drill pipes to maintain adequate airflow for sample retrieval. While RC drilling is often more cost-effective than diamond core drilling for shallower exploration, the economic advantage can diminish at greater depths.

The choice of drill pipe diameter also plays a role; larger diameter pipes are needed for deeper holes to accommodate the increased air volume, but these are more expensive and require more robust handling equipment. Ultimately, the optimal depth for RC drilling is a balance between the project’s geological targets, budget constraints, and the capabilities of the available equipment.

| Depth (meters) | Typical Air Pressure (psi) | Considerations |

| 0-50 | 100-150 | Shallow exploration, minimal pressure needed |

| 50-100 | 150-200 | Increased pressure for cuttings removal |

| 100-200 | 200-300 | Moderate depth, requires more powerful compressor |

| 200-300 | 300-400 | Approaching typical depth limit for smaller rigs |

| 300-500 | 400-600 | Common range for larger RC drilling operations |

| 500-800+ | 600+ | Requires high-capacity rigs and powerful boosters, depth limited by groundwater and rig capacity |

RC Drilling Benefits

RC drilling offers a compelling suite of advantages, making it a preferred method for many mineral exploration and geotechnical projects. Its efficiency and cost-effectiveness, coupled with its ability to provide rapid and relatively clean samples, contribute significantly to streamlined operations and informed decision-making.

Speed and Efficiency

RC drilling boasts significantly faster penetration rates compared to other drilling methods like diamond core drilling. The continuous removal of cuttings via compressed air allows for quicker progress, enabling faster evaluation of potential mineralized zones or subsurface conditions. This speed translates to reduced project timelines and quicker turnaround on results.

Cost-Effectiveness

Generally, RC drilling operations are more cost-effective than diamond drilling, particularly for initial exploration phases and shallower depths. The simpler equipment and faster drilling cycles contribute to lower operational expenses, making it an attractive option for large-scale sampling programs and budget-conscious projects.

Sample Quality

RC drilling provides relatively dry and uncontaminated rock chip samples. The rapid removal of cuttings minimizes downhole contamination and weathering, offering a more representative sample for geochemical analysis compared to methods where cuttings can be exposed to drilling fluids for extended periods.

Versatility

RC drilling can be effectively employed in a variety of geological formations, ranging from soft to moderately hard rock. It is also adaptable to different terrains and can operate with relatively minimal water usage compared to some other drilling techniques, making it suitable for arid or water-scarce environments.

Real-Time Sample Collection

The continuous and immediate collection of samples at the surface allows for real-time monitoring and analysis of the encountered geology. This immediate feedback enables quick adjustments to the drilling program based on the lithology and mineralization encountered, optimizing the exploration process.

Environmental Considerations

Compared to some other drilling methods, RC drilling can have a lower environmental impact, especially in terms of water consumption. The relatively dry operation reduces the need for large volumes of drilling fluids and the associated disposal challenges, making it a more sustainable option in certain environments.

Is RC Better Than Percussion Drilling?

RC drilling and traditional percussion drilling share the fundamental principle of using impact to break rock. However, they differ significantly in how cuttings are managed and the overall efficiency. Traditional percussion drilling, often called cable tool drilling, involves repeatedly lifting and dropping a heavy drill bit to crush the rock. The broken material is then periodically removed using a bailer. This process is generally slower and less efficient for continuous sample collection compared to RC drilling.

RC drilling employs a more advanced method using compressed air to power a downhole hammer and, crucially, to immediately and continuously evacuate the rock cuttings through a dual-walled drill rod system.

This reverse circulation of air and cuttings provides several advantages over traditional percussion drilling, including faster penetration rates, the collection of relatively dry and uncontaminated samples at the surface in real-time, and a reduced risk of cross-contamination downhole.

While traditional percussion drilling can be effective in certain shallow applications and some consolidated formations, RC drilling is generally considered a more efficient and accurate method for mineral exploration and geotechnical investigations requiring continuous and representative samples.

What is the Difference Between AC and RC Drilling?

While both Air Core (AC) and Reverse Circulation (RC) drilling methods utilize compressed air to bring rock cuttings to the surface, their key differences lie in their application, depth capabilities, and sample quality. AC drilling is generally a shallower, faster, and more cost-effective method primarily used for first-pass exploration in unconsolidated ground, while RC drilling is more robust, capable of deeper penetration, and provides higher quality, less contaminated samples, making it suitable for more detailed resource definition.

- Air Core (AC) Drilling: This method uses a three-bladed steel or tungsten drill bit to bore into softer, unconsolidated materials like clays, sands, and weathered rock. Compressed air flushes the cuttings up an inner tube, making it quick and economical for shallow exploration. However, it struggles with hard rock and generally yields smaller, sometimes dustier samples.

- Reverse Circulation (RC) Drilling: RC drilling employs a downhole hammer and a dual-walled drill pipe system. Compressed air powers the hammer to pulverize harder rock formations, and the cuttings are then forced up the inner tube by the “reverse” flow of air. This process provides larger, relatively dry, and highly representative samples, ideal for deeper exploration and accurate grade control in mining.

RC Drilling vs Diamond Drilling

RC drilling and diamond drilling are both vital methods in mineral exploration, yet they cater to distinct objectives. RC drilling excels in rapid, cost-effective bulk sampling, while diamond drilling prioritizes the recovery of intact core samples for detailed geological and structural analysis.

The choice between them hinges on the project’s specific requirements for speed, cost, and the level of geological detail needed.

Sample Quality and Information

RC drilling produces crushed rock chips, which are valuable for quick geochemical analysis and identifying mineralized zones. However, the fragmented nature of the samples can obscure the original rock texture and structural relationships. In contrast, diamond drilling yields continuous, cylindrical core samples that preserve the in-situ rock structure, allowing for detailed examination of lithology, alteration, veining, and structural features. This intact core is crucial for accurate geological modeling and resource estimation.

Speed and Cost Efficiency

RC drilling generally boasts significantly faster penetration rates compared to diamond drilling, making it a more time-efficient method for initial exploration phases and large-scale sampling programs. The operational costs of RC drilling are also typically lower due to simpler equipment and faster drilling cycles. Diamond drilling, while providing superior sample quality, is a slower and more expensive technique, often reserved for follow-up drilling on promising targets where detailed geological information is paramount.

Depth Capability and Ground Conditions

RC drilling is most effective at shallower to medium depths, typically reaching up to 500 meters, although deeper drilling is possible with specialized equipment. It performs well in various rock types, but very hard or highly fractured ground can pose challenges for sample recovery. Diamond drilling, on the other hand, is capable of achieving much greater depths, exceeding 1000 meters, and can penetrate virtually any rock type, including very hard and abrasive formations. This makes it the preferred method for deep exploration targets and challenging geological environments.

Conclusion

RC drilling stands out as an efficient and cost-effective method for mineral exploration and geotechnical investigations, offering rapid penetration and sample recovery. Its ability to function in diverse terrains with minimal water usage further enhances its practicality. While it may provide less detailed geological information compared to other methods, its speed and cost savings make it a preferred choice for initial exploration phases.

For businesses seeking reliable and high-performance drilling tools for RC or other drilling applications, Sinodrills offers a comprehensive range of wholesale options. As a specialized manufacturer, they provide top hammer drilling tools, DTH drilling tools, drag bits, and self-drilling anchor tools, catering to various drilling needs in mining, construction, and tunneling.

In conclusion, RC drilling is a valuable technique in subsurface exploration, balancing efficiency and cost. To support such operations with quality equipment, consider sourcing wholesale drilling tools from Sinodrills, a reputable supplier in the industry.