RC drilling and diamond drilling stand as primary methods in subsurface exploration, each with unique strengths. RC drilling offers rapid, cost-effective bulk sample acquisition, ideal for initial resource evaluation. Conversely, diamond drilling excels in retrieving intact core samples, crucial for detailed geological and structural analysis.

The fundamental divergence lies in their sample output and operational approach. RC drilling yields fragmented rock chips through percussion and air flushing, prioritizing speed and economy. Diamond drilling, however, employs a rotating diamond-studded bit to cut solid, continuous cores, emphasizing sample integrity for in-depth geological understanding.

What is RC Drilling

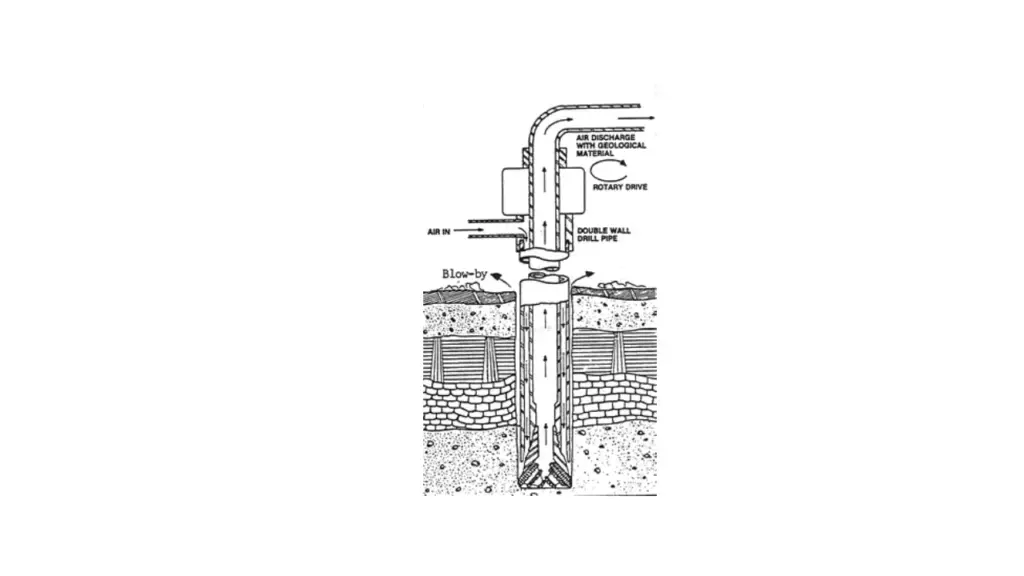

RC drilling, short for reverse circulation drilling, is a percussion drilling technique that uses compressed air to power a downhole hammer and simultaneously lift rock cuttings to the surface through a dual-walled drill rod system.

Compressed air is forced down the outer tube, and the pulverized rock samples are carried back up the inner tube to be collected via a cyclone separator. This method is favored for its speed, cost-effectiveness, and ability to provide relatively dry and uncontaminated samples, making it a common choice for mineral exploration and geotechnical investigations.

RC Drilling Hammers

RC drilling hammers are the driving force behind the rock pulverization in reverse circulation drilling. These downhole pneumatic hammers function similarly to conventional DTH (Down-The-Hole) hammers but are distinguished by an inner tube that runs through their center. This inner tube is crucial for the reverse circulation of cuttings.

Compressed air powers an internal piston that rapidly strikes the drill bit, breaking the rock. The resulting cuttings are then forced into ports on the face of the bit and travel up through the inner tube of the hammer and drill rods to the surface for collection. RC hammers are designed for high performance and reliability in various exploration drilling applications.

What is Diamond Drilling

Diamond drilling is a drilling method that utilizes a diamond-impregnated drill bit to cut a cylindrical core sample from subsurface formations. As the drill bit rotates, the diamonds, being extremely hard, grind away at the rock, allowing a solid core to enter the core barrel attached to the drill string. This intact core is then retrieved to the surface, providing a continuous and undisturbed sample that is invaluable for detailed geological analysis, including lithology, structural measurements, and mineralogical studies.

Diamond drilling is favored when high-quality, representative samples are required for accurate resource evaluation and geotechnical investigations, capable of penetrating very hard rock and reaching significant depths.

RC Drilling vs Diamond Drilling

RC drilling and diamond drilling represent distinct approaches to subsurface investigation, each with its own strengths and applications. RC drilling prioritizes rapid, cost-effective bulk sampling, delivering crushed rock chips for quick analysis. Conversely, diamond drilling focuses on retrieving intact core samples, essential for detailed geological and structural interpretation.

The selection between these drilling methods hinges on the project’s specific demands regarding speed, budget, and the granularity of geological information needed.

Sample Quality and Information

RC drilling yields fragmented rock chips, which are primarily used for geochemical analysis to identify potential mineralization. While these samples provide valuable elemental data, the destruction of the original rock fabric limits the ability to study textural relationships, structural features, and detailed mineralogy in their original context. This can make precise geological modeling more challenging, especially when understanding the spatial distribution and orientation of geological units is critical.

Diamond drilling, in contrast, provides continuous, cylindrical core samples that meticulously preserve the in-situ characteristics of the subsurface. These intact cores allow geologists to conduct detailed macroscopic and microscopic examinations, identifying lithological boundaries, alteration styles, veining patterns, and structural orientations with high accuracy. The preservation of the original rock fabric is crucial for constructing robust geological models, estimating resource volumes, and understanding the geological controls on mineralization.

Speed and Cost Efficiency

RC drilling generally achieves significantly faster penetration rates compared to diamond drilling. The percussive action of the downhole hammer and the efficient removal of cuttings via compressed air allow for quicker progress, especially in softer to medium-hard rock formations. This rapid drilling translates to reduced rig time and lower overall operational costs per meter drilled, making RC drilling an attractive option for large-scale initial exploration programs where covering ground quickly is a priority.

Diamond drilling, with its grinding action and the need to retrieve core samples, typically progresses at a slower pace. The complexity of the equipment, the need for skilled operators to ensure good core recovery, and the often higher costs associated with consumables like diamond bits contribute to a higher cost per meter. While slower and more expensive, the value of the detailed geological information obtained from diamond core often outweighs the initial cost, particularly in later stages of exploration and resource definition.

Depth Capability and Ground Conditions

RC drilling is most effective at shallower to medium depths, commonly reaching up to 500 meters, although specialized rigs can go deeper. Its performance can be affected by significant groundwater inflow, which can hinder cuttings removal, and very hard or highly fractured ground, which can impact sample quality and drilling efficiency.

Diamond drilling excels at reaching greater depths, often exceeding 1000 meters, and can effectively penetrate virtually any rock type, including extremely hard, abrasive, or unconsolidated formations. The ability to use drilling fluids to stabilize the borehole and cool the bit enhances its capability in challenging ground conditions. This makes diamond drilling the preferred method for deep exploration targets and geological environments where core recovery is paramount, regardless of rock hardness or depth.

Environmental Impact

RC drilling generally has a lower environmental footprint compared to diamond drilling, primarily due to its reduced water consumption. In arid regions, this is a significant advantage. The disposal of dry cuttings is also often simpler than managing large volumes of drilling fluids and sludge generated by diamond drilling. However, the high-pressure air used in RC drilling can create dust, requiring dust suppression measures in some environments.

Diamond drilling typically requires significant amounts of water for cooling the drill bit and flushing cuttings, which can be a concern in water-scarce areas. The disposal of used drilling fluids and the associated sludge containing rock fines and additives requires careful management to minimize environmental contamination. However, advancements in drilling fluid recycling and environmentally friendly additives are helping to mitigate these impacts.

Sample Handling and Analysis

RC drilling produces a bulk sample of crushed rock chips for each drilling interval, typically 1-3 meters. These samples are relatively easy to handle and are often directly processed for geochemical analysis on-site or sent to a laboratory. The larger sample volume can be advantageous for achieving representative analytical results, especially in heterogeneous mineralization.

Diamond drilling yields cylindrical core samples that require careful handling and storage to preserve their integrity. The core is typically logged geologically, photographed, and then selectively sampled for laboratory analysis. While providing detailed visual and structural information, the amount of material available for destructive analysis from a core sample is limited compared to RC chips, potentially requiring more strategic sample selection.

How to Choose RC Drilling and Dimaond Drilling

Selecting between RC and diamond drilling hinges on the project’s objectives and constraints. If rapid, cost-effective preliminary assessment and bulk sampling for geochemical analysis are the priority, and the target depths are moderate, RC drilling is often the better choice.

However, when detailed geological and structural information from intact core samples is crucial for resource definition and complex geological environments, diamond drilling is preferred, despite its higher cost and slower pace. Consider the following factors:

- Project Budget: RC drilling generally has lower operational costs.

- Depth of Target: Diamond drilling is better suited for deep exploration.

- Required Sample Quality: Diamond drilling provides intact core, while RC yields crushed chips.

- Speed of Drilling: RC drilling offers faster penetration rates.

- Geological Complexity: Diamond core is essential for detailed structural analysis.

- Type of Analysis: RC samples are ideal for bulk geochemical analysis; diamond core allows for diverse studies.

Conclusion

In essence, RC drilling offers speed and cost-efficiency for initial resource evaluation, providing quick geochemical data from crushed samples. Diamond drilling, conversely, delivers high-quality, intact core samples crucial for detailed geological and structural understanding, albeit at a higher cost and slower pace. The project objectives dictate the most suitable method.

For businesses requiring reliable drilling equipment for either RC or diamond drilling operations, Sinodrills provides a comprehensive selection of wholesale drilling tools. Their expertise in manufacturing top hammer, DTH, and other drilling tools ensures access to high-performance solutions for diverse exploration needs.

Ultimately, the choice between RC and diamond drilling hinges on the balance between budget, speed, and the level of geological detail required. Regardless of the chosen method, sourcing quality tools from suppliers like Sinodrills is essential for efficient and successful drilling campaigns.