Custom Ring Bit Casing System Manufacturer in China

We specialize in manufacturing custom ring bit casing systems, designed to your specific drilling needs. Our solutions are engineered to excel in challenging geological conditions, ensuring superior performance and stability for applications like water well, geothermal, and micropiling. We offer a full range of sizes and configurations to provide durable, reliable tools for your project’s success.

Sinodrills - Your Trusted Ring Bit Casing System Manufacturer from China

Sinodrills is a trusted manufacturer from China specializing in ring bit casing systems. Our advanced tools are engineered to provide efficient and reliable solutions for stabilizing boreholes in challenging ground conditions. We are dedicated to serving the geothermal, water well, and foundation drilling industries with superior performance and unwavering customer satisfaction.

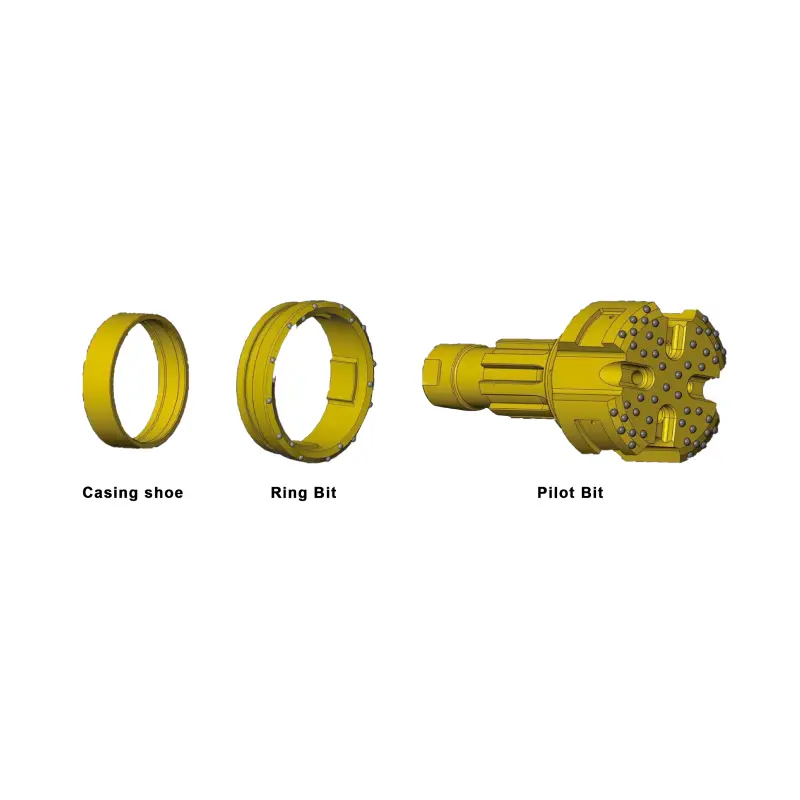

Concentric Casing System With Ring Bit

Pilot Bit: This is the primary cutting tool at the front of the assembly. It is responsible for drilling the initial pilot hole and guiding the entire system through the formation.

Ring Bit: The ring bit surrounds the pilot bit and is a key component. It reams the hole to a larger diameter, allowing the casing pipe to be advanced simultaneously with the drilling.

Casing Shoe: Welded to the bottom of the casing pipe, the casing shoe is a ring-like part. It helps the casing advance smoothly into the hole and prevents it from getting stuck.

DTH Hammer: The down-the-hole (DTH) hammer is the engine of the system. It delivers powerful, high-frequency percussive blows that drive the pilot bit and ring bit through rock and soil.

Casing Pipe: The casing pipe is the central element that stabilizes the borehole. It is driven into the ground as the drilling progresses, creating a secure, permanent well or foundation.

Concentric Drilling System with Ring Bits

Geothermal and Water Well Drilling: The system is ideal for drilling through unstable overburden to reach bedrock. It ensures a stable borehole for installing casings, critical for the longevity and productivity of both geothermal and water wells.

Foundation Piling and Micropiling: It’s used to create a secure foundation in challenging ground conditions. The system drives casing for piles and micropiles, preventing collapse and providing the necessary support for construction projects.

Mining and Quarrying: The ring bit system is used to install blast holes and exploration bores in broken or fractured rock formations. It provides a stable hole for loading explosives or for geological sampling, improving safety and efficiency.

Tunneling and Horizontal Boring: This system is highly effective for installing tunnels and pipelines in unstable ground. It ensures the casing is installed with precision, preventing ground collapse during horizontal drilling operations.

Various Ring Bit Casing System

RC drilling rods with metzke thread

We offer custom Odex casing systems and Odex casing bits designed for your specific needs. Our solutions are engineered to handle challenging overburden and unstable ground, ensuring borehole stability and efficiency. We provide a range of sizes and configurations, delivering durable and reliable tools for water well, geothermal, and micropiling applications.

retrievable symmetric casing system with ring bits

We provide custom retrievable symmetric casing systems with ring bits, designed to minimize costs and environmental impact. Our systems allow you to recover and reuse the casing, perfect for temporary applications like soil nailing, micropiling, or when a permanent casing is not required. We offer durable, high-quality tools for efficient, cost-effective drilling.

dTH ring bit multi-use casing system

We manufacture multi-use DTH ring bit casing systems, offering a versatile solution for diverse drilling projects. Our DTH casing system are designed for applications where the casing needs to be retracted and re-used, providing significant cost savings. We customize systems for various DTH hammers and casing sizes, ensuring high-performance and durability in challenging ground conditions.

rock drilling concentric casing system with ring bits

We provide custom rock drilling concentric casing systems with ring bits, meticulously engineered for superior performance in demanding geological conditions. Our solutions are designed to simultaneously drill and case a hole, ensuring borehole stability in formations with gravel, fractured rock, and boulders. We offer tailored dimensions and configurations to perfectly match your project’s needs.

ring bit retrievable drilling system

We manufacture custom ring bit retrievable drilling systems, providing a cost-effective solution for temporary casing projects. Our systems are engineered for easy retrieval of the casing and ring bit, allowing them to be reused on multiple jobs. We offer a full range of sizes and configurations to meet your specific drilling needs, ensuring high performance and efficiency.

Customize Your Desired Ring Bit Casing System

Material Selection

We meticulously select high-grade steel alloys for the main pilot bit and the ring bit to guarantee exceptional strength and wear resistance. For projects in corrosive environments, we can use specific alloys that offer enhanced protection, extending the tool’s lifespan and maintaining its performance under harsh conditions.

Drilling Diameter

We can customize the diameter of the ring bit and pilot bit to match your required casing size. This precision ensures a perfect fit, providing stable drilling and allowing the casing to be driven efficiently. We can also tailor the system for specific hole sizes, guaranteeing optimal performance for your particular application.

Carbide Button Configuration

The placement and type of carbide buttons on both the pilot and ring bits are crucial for cutting efficiency. We can adjust the pattern, size, and grade of these buttons to suit different rock formations, from soft soils to hard rock, maximizing penetration rates and tool life while minimizing operational costs.

Flushing System and Air Holes

We can customize the flushing system, including the size and configuration of the air or water holes. This is critical for efficiently clearing cuttings and debris from the borewell. By tailoring the fluid flow, we ensure the drill bits remain clean and cool, improving both drilling speed and the longevity of the entire casing system.

what is Casing sytem?

A casing system in drilling refers to the process and components used to line the inside of a drilled hole with steel pipe, known as casing. This is a critical step in well construction, as it serves multiple purposes: it prevents the wellbore from collapsing, isolates different geological formations to prevent fluid contamination between them, and provides a stable conduit for drilling deeper.

In conventional drilling, a hole is drilled and then the drill string is removed so the casing can be run in and cemented. However, in modern “casing while drilling” systems, specialized tools like the ring bit casing system allow the casing to be installed simultaneously with the drilling process, significantly improving efficiency and wellbore stability, especially in unstable ground conditions.

what is ring bit in Casing sytem?

A ring bit is a crucial component of a concentric casing system, used for simultaneously drilling and installing casing pipe. It’s essentially a reaming tool with carbide buttons that works in conjunction with a central pilot bit.

As the pilot bit drills the initial hole, the ring bit follows behind, reaming the hole to a larger diameter, just wide enough for the casing to advance into the ground. The ring bit is attached to the casing and receives the percussive and rotational energy from the drill hammer, which is transferred through the pilot bit.

This integrated process is highly effective for drilling through loose, unstable, or bouldered ground formations where the wellbore would otherwise collapse.

The ring bit stays in the hole with the casing, providing a permanent lining to the well.

what does ring bit casing system have?

A ring bit casing system is composed of several key components that work together to drill and install casing simultaneously.

The casing drill system is designed to be highly efficient, especially in difficult ground conditions where conventional drilling methods would lead to borehole collapse. The primary components include:

Pilot Bit: This is the inner, central drill bit that cuts the main hole. It’s connected to the down-the-hole (DTH) hammer and transmits the percussive and rotational energy to the rest of the system.

Ring Bit: This is a larger, outer bit that reams the hole to a diameter slightly larger than the casing. It’s connected to the pilot bit and is responsible for creating the space for the casing to be advanced into the ground.

Casing Shoe: This component is welded to the bottom of the casing pipe and is what transfers the pulling force from the ring bit to the casing, driving it into the ground as the drilling progresses.

Casing Pipe: The pipe itself, which is installed into the ground to line the borehole and provide stability.

where to use ring bit casing system?

A ring bit casing system is an ideal solution for a variety of drilling applications, particularly in unstable, difficult ground conditions. It is used in situations where the borehole has a high risk of collapsing, such as when drilling through loose soil, sand, gravel, fractured rock, or formations with large boulders.

By simultaneously drilling and installing the casing, the system ensures the integrity of the hole and prevents it from caving in, which saves time and cost while improving overall safety. Its efficiency and reliability make it a preferred choice for numerous project types.

The primary applications include:

Water Well and Geothermal Drilling: Ensures well integrity in various ground conditions.

Foundation and Piling Construction: Used for creating stable foundations, micropiles, and anchor installations.

Tunneling and Horizontal Drilling: Provides a safe and effective way to pre-support and line the ground ahead of the main tunnel face.

Mining and Quarrying: Used for applications where a permanent or retrievable casing is needed.

Environmental and Geotechnical Projects: Ideal for site investigation and monitoring wells in unstable overburden.

Send Your Inquiry Now

All-in-one Ring Bit Casing System Solutions for Your Project

We offer comprehensive ring bit casing system solutions that we can fully customize for your specific project. From selecting the ideal materials and configuring the perfect drilling diameter to optimizing the carbide buttons and shank, we ensure a perfect fit with your equipment. We also tailor the flushing system for optimal performance in your ground conditions.