Custom Rock Drill Rods Manufacturer in China

Looking for a custom rock drill rods manufacturer in China? Look no further. Our company specializes in producing high-quality, tailor-made drill rods to meet your specific needs. We offer a wide range of materials and thread configurations for mining, quarrying, and construction applications. Contact us today for reliable and durable drilling solutions.

Sinodrills - Your Trusted Rock Drill Rods Manufacturer from China

Sinodrills is a trusted manufacturer of rock drill rods and other drilling tools in China. With over two decades of experience and two production facilities, Sinodrills offers high-quality products compatible with leading global brands. Their focus on reliability, competitive pricing, and professional service has made them a leading supplier for the mining, construction, and quarrying industries worldwide.

Your Leading Rock Drill Rod Manufacturer from China

Looking for a reliable rock drill rod manufacturer in China? We offer top-tier drilling tools designed for durability and high performance. Our products are compatible with major global brands and are ideal for mining, construction, and quarrying.

High-quality materials for extended service life

Customizable options to meet your specific project needs

Competitive pricing without compromising on quality

rock Drill Rod Benefits

Exceptional Durability and Longevity Rock drill rods are manufactured from high-grade alloy steel and undergo specialized heat treatments. This makes them incredibly strong, enabling them to withstand extreme stress, percussive forces, and torsion for a prolonged service life.

Efficient Energy Transfer A key function of a rock drill rod is to transmit the maximum impact energy from the rock drill to the drill bit. Their precision engineering ensures minimal energy loss, resulting in faster penetration rates and higher drilling efficiency.

Enhanced Drilling Accuracy The rigidity and design of high-quality drill rods minimize hole deviation, leading to straighter and more uniform boreholes. This precision is crucial for effective blasting, safe tunneling, and stable foundation work in construction projects.

Adaptability to Diverse Applications Available in various lengths, diameters, and thread configurations, rock drill rods can be tailored for specific rock formations and drilling conditions. This versatility makes them essential for mining, quarrying, construction, and geotechnical projects.

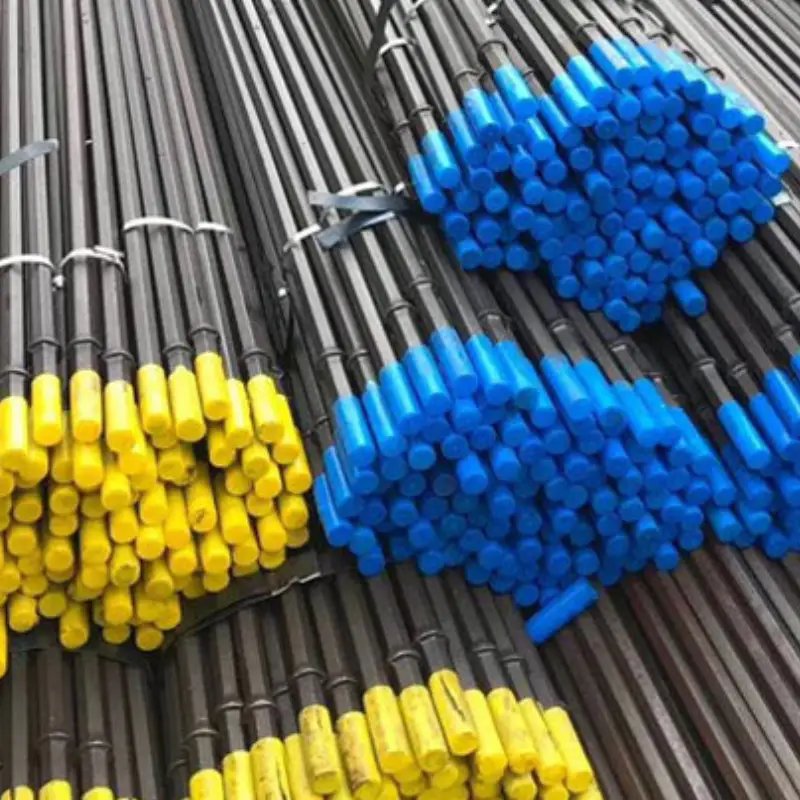

Various Rock Drill Rods

tapered rock drill rods

We offer a comprehensive range of tapered rock drill rods designed for efficient drilling in mining, quarrying, and construction. Our rods are manufactured from premium alloy steel, ensuring exceptional durability and superior energy transmission. Available with various taper angles and lengths, they provide a reliable and cost-effective solution for small-hole drilling applications, ensuring high performance and a long service life.

rock extension drill rods

We specialize in manufacturing rock extension drill rods designed for deep-hole drilling. Our rods are crafted from premium alloy steel with advanced heat treatment for superior strength and wear resistance. They are compatible with major global brands and come in various thread types like R25, R32, R38, T38, T45, and T51 to meet diverse drilling needs.

hexagon rock drill rods

Need custom hexagon rock drill rods? We offer a comprehensive solution for your specific drilling needs. Our manufacturing capabilities allow us to produce tailor-made rods with various lengths, shank sizes, and collar configurations. We use premium-grade materials and advanced heat treatment to ensure superior durability and optimal performance in all rock conditions.

steel metal rock drill rods

We manufacture premium steel metal rock drill rods designed for superior performance and durability. Our rock drill rods are crafted from high-grade alloy steel, ensuring they can handle the most demanding drilling applications. We offer a comprehensive range of threaded and tapered rods, compatible with leading brands, to meet the specific needs of mining, construction, and quarrying projects.

custom rock drill rods and bits for drilling

We manufacture custom rock drill rods and bits, providing tailored solutions for your drilling needs. Our products are made from premium materials, ensuring superior durability and performance. We offer a wide range of custom lengths, diameters, and thread types for mining, construction, and quarrying applications. Contact us to design the perfect drilling tools for your project.

round rock drill rods

Need custom round rock drill rods? We specialize in manufacturing high-quality, tailored drilling tools to your exact specifications. Our rods are made from premium alloy steel, ensuring exceptional durability and performance for your mining, quarrying, and construction projects. We offer various lengths, diameters, and thread types to meet your unique operational demands.

Customize Your Desired Rock Drill Rods

Steel Grade and Heat Treatment

We use different grades of high-quality alloy steel to match the specific demands of your drilling conditions. Our advanced heat treatment processes are carefully controlled to optimize the rod’s hardness and toughness, providing superior wear resistance and a longer service life in abrasive or high-stress environments.

Thread Type and Configuration

We can manufacture rods with various thread types, including R, T, and a variety of proprietary designs, to ensure a perfect connection with your existing rock drill and bits. The thread configuration can be optimized for specific applications, enhancing energy transfer and minimizing the risk of thread stripping or failure.

Rod Diameter and Length

We can produce rods in a wide range of standard and custom diameters to match your required hole size. The length of the rods can also be precisely adjusted to achieve the desired drilling depth. This customization allows for more efficient drilling without the need for unnecessary couplings.

Anti-Corrosion and Surface Treatment

For operations in corrosive environments, we offer specialized anti-corrosion coatings and surface treatments. These treatments protect the rods from rust and chemical degradation, significantly extending their operational life and reliability. The surface can also be treated to enhance fatigue strength and reduce friction.

what are rock drill rods?

Rock drill rods are specialized steel tubes that are a fundamental component of a drill string, used in mining, quarrying, construction, and geotechnical projects. Their primary purpose is to connect the rock drill machine to the drill bit, efficiently transmitting the powerful percussive impact energy and rotational torque from the drill to the bit. Made from alloy steel and subjected to advanced heat treatments, these rods are engineered to withstand extreme stresses, including tension, compression, bending, and high-frequency impacts, ensuring durability and a long service life in harsh, abrasive rock formations.

what are rock drill rods made of?

Rock drill rods are primarily made from alloy steels, specifically engineered to handle the intense stress and repeated impacts of rock drilling. These steels are selected for their exceptional strength, toughness, and durability. The exact composition often includes a blend of carbon steel with additional alloying elements to enhance specific properties.

High Carbon Steel: Provides a foundational hardness and wear resistance, making the rods strong enough to withstand abrasive conditions.

Alloy Elements: Metals like chromium, molybdenum, and nickel are added to improve the steel’s overall performance. This enhances properties like fatigue strength, resistance to heat, and toughness, which are crucial for preventing cracks and breakage.

Heat Treatment: The steel undergoes a specialized heat treatment process, such as carburizing, to create a hard outer casing while maintaining a tougher, more flexible core. This unique combination allows the rod to absorb impact energy without fracturing, significantly extending its service life.

what are rock drill rods used for?

Rock drill rods are versatile tools used across a range of industries to create holes in rock and other hard materials. Their primary function is to serve as the critical link in a drill string, transferring the energy from a drilling machine to a drill bit. This allows for the efficient and precise boring of holes for various applications.

Mining and Quarrying: They are essential for creating blast holes to break up large rock formations for mineral extraction and aggregate production. The rods are designed to withstand constant impact and rotational forces in harsh environments.

Construction and Civil Engineering: Rock drill rods are used for a variety of tasks, including drilling holes for foundations, anchors, and micro-piles to stabilize structures and slopes. They also play a vital role in tunneling and road construction for both excavation and rock reinforcement.

Geotechnical and Exploration Drilling: In this field, they are used to drill deep into the earth to obtain rock and soil samples. These samples are then analyzed to assess ground conditions for new construction projects or to search for mineral deposits.

how to choose suitable rock drill rods?

Choosing the right rock drill rod is crucial for ensuring drilling efficiency, safety, and cost-effectiveness.

The selection process should be guided by several key factors related to the specific project and equipment being used.

1. Match Your Drilling Method and Equipment

The type of rod must be compatible with your drilling rig. For top-hammer drilling, you will need extension rods (MF or male-female rods) or integral rods. For Down-the-Hole (DTH) drilling, specialized DTH rods are required, which are designed to carry compressed air to the hammer. The thread type and size of the rod must also match your shank adapter and drill bits.

2. Consider Rock and Ground Conditions

The geological formation is a major factor. For hard, abrasive rock, a rod made from a high-grade alloy steel with advanced heat treatment is necessary for durability and wear resistance. In softer formations, a standard rod may suffice. The presence of fractures or complex geology can also influence the choice, as some rods offer greater rigidity to maintain hole straightness.

3. Determine Rod Diameter and Length

The diameter of the rod is generally chosen based on the required hole diameter. A larger rod diameter provides greater rigidity, which helps prevent hole deviation, especially in deep drilling. The length of the rods should be selected based on the total depth of the hole you need to drill. Using longer rods can reduce the number of connections, which saves time and minimizes points of potential failure.

4. Evaluate Customization and Quality

Choosing a reputable manufacturer is essential. Look for a company that offers a range of customization options, from steel grade and heat treatment to specific thread configurations. A high-quality rod, while potentially more expensive upfront, will provide better performance, a longer service life, and lower overall project costs due to reduced downtime and replacements.

Send Your Inquiry Now

All-in-one Rock Drill Rods Solutions for Your Project

Discover your all-in-one rock drill rods solution from our expert team. We provide a full range of high-performance drill rods, from tapered and threaded to integral designs. Our products are made with superior materials and advanced manufacturing techniques to ensure exceptional durability and efficiency. We are your reliable partner for all your mining, quarrying, and construction drilling needs.